Elastic anti-overflow recovery device and recovery method of roller coating equipment

A recycling device and anti-spill technology, which is applied to devices and coatings that apply liquid to the surface, which can solve the problems of wasting paint, polluting roller coating equipment and production environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

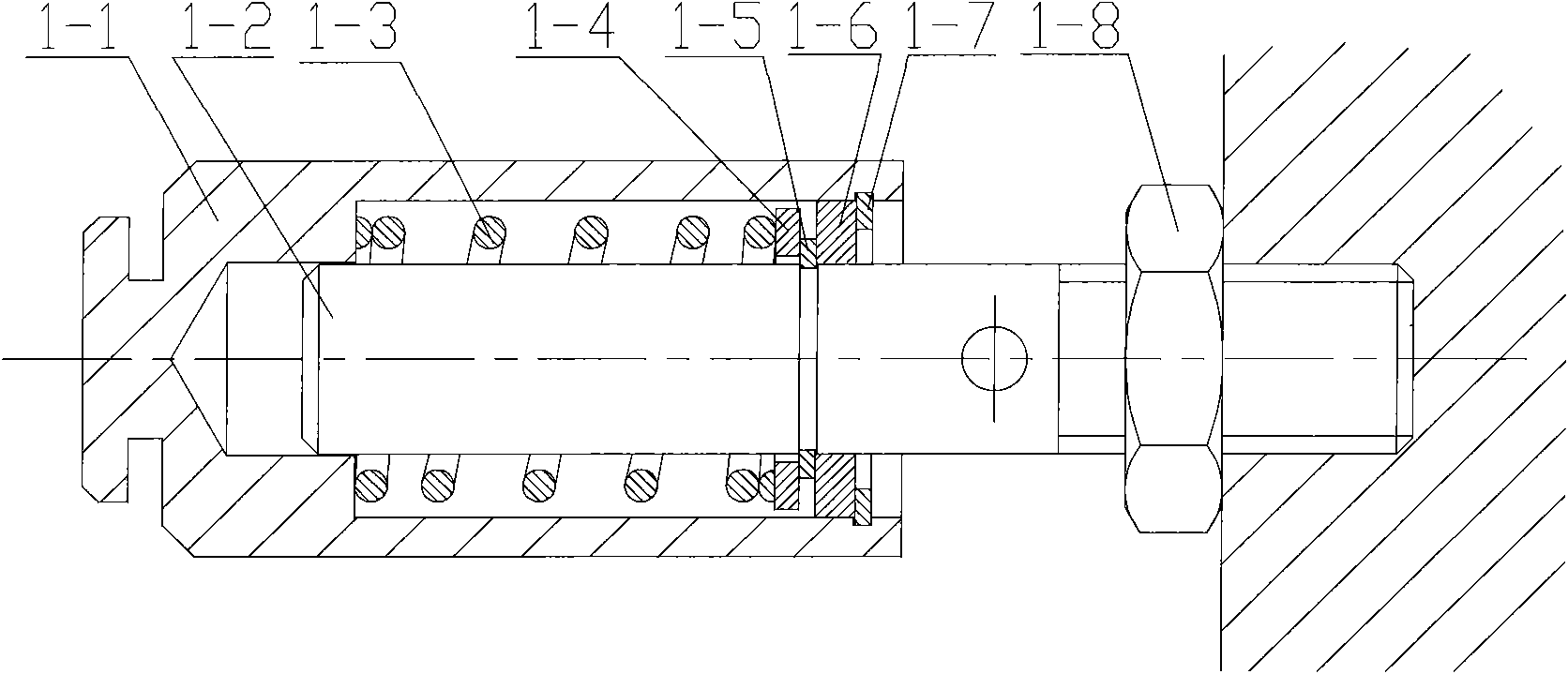

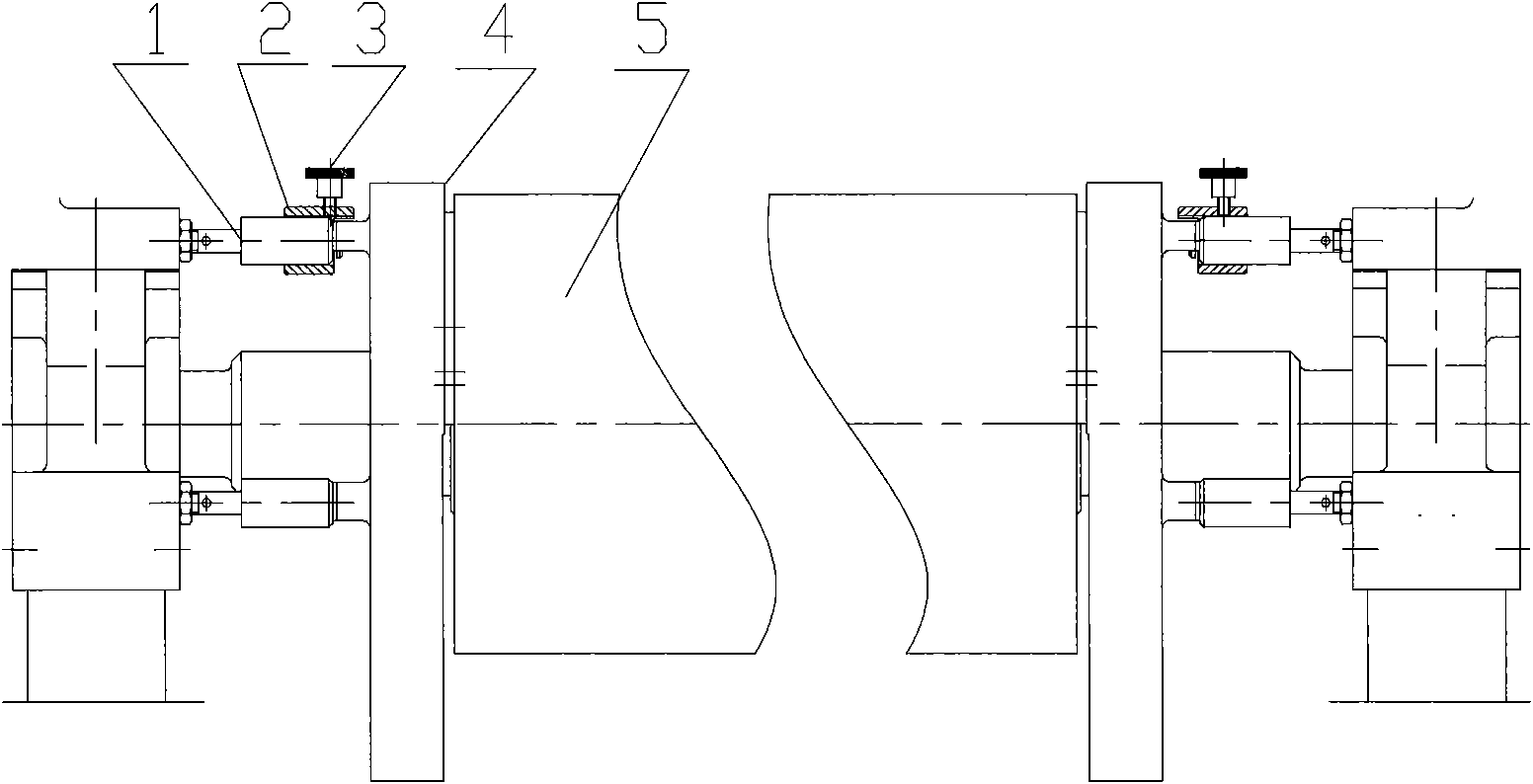

[0010] Embodiment 1: see attached figure 1 and 2 . Elastic anti-spill recovery device for roller coating equipment, the spring assembly 1 is fixed on the frame, the material receiver 4 is connected to the spring assembly 1 through the fixing bolt 3, the material receiver 4 is located between the spring assembly 1 and the roller assembly 5 The receiving edge of the device 4 is elastically matched with the end face of the roller assembly 5 . The spring assembly 1 is composed of a spring sleeve 1-1, a spring pin 1-2, a compression spring 1-3, a circlip 1-7 for a hole, and a nut 1-8. One end of the spring pin 1-2 is located at the spring sleeve 1-2. 1 and the spring pin 1-2 is covered with a stage clip 1-3, and the hole is stuck in the inner port of the spring sleeve 1-1 with a circlip 1-7 and the other part of the stage clip 1-3 limit spring pin 1-2 One end is covered with a nut 1-8, and its retaining ring 1-6 is set on the spring pin 1-2 and is located inside the retaining ri...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the elastic anti-spill recovery method of roller coating equipment, the elastic component 1 is fixed on the frame, the material receiver 4 is fixed on the elastic component, and the material receiver 4 is movable connection and can be used at any time When it is removed, the material receiver 4 can be close to the two ends of the roller assembly 5 due to the support of the elastic component 1. When there is a gap between the two ends of the roller component 5 during work, the material receiver 4 will automatically fill in under the support of the elastic component 1. Try to make the paint can not be splashed outside the receiver 4 of the paint circulation system, so that the paint will not be wasted, and the roller coating equipment and the production environment will not be polluted, so as to achieve the anti-spill recovery function from the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com