Novel moment limiter for crane

A torque limiter and crane technology, applied to cranes and other directions, can solve problems such as the inability to accurately grasp the position and real-time status of the crane, the failure of the torque limiter to work normally, and the error alarm of the torque limiter. It is suitable for promotion, complete functions, The effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

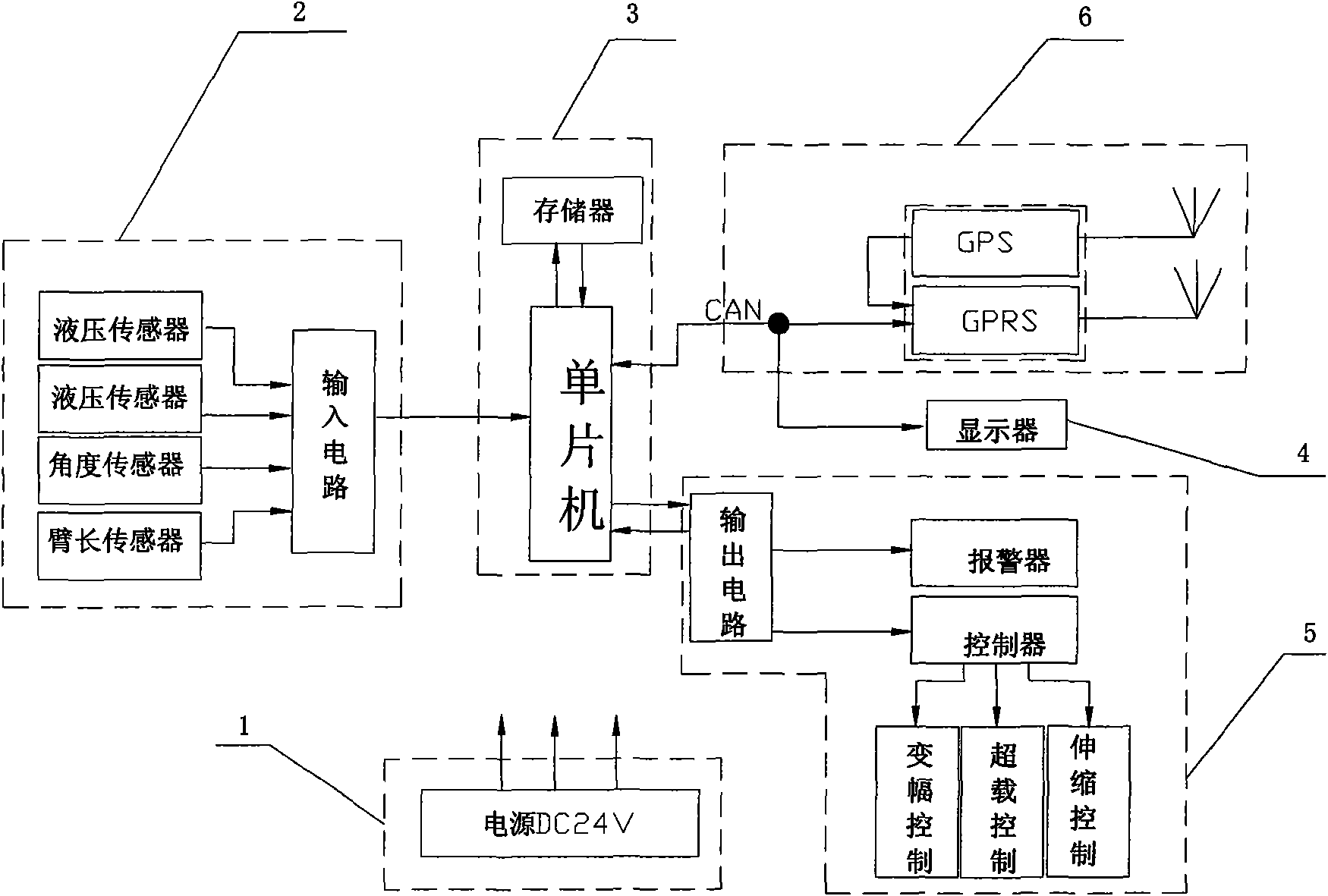

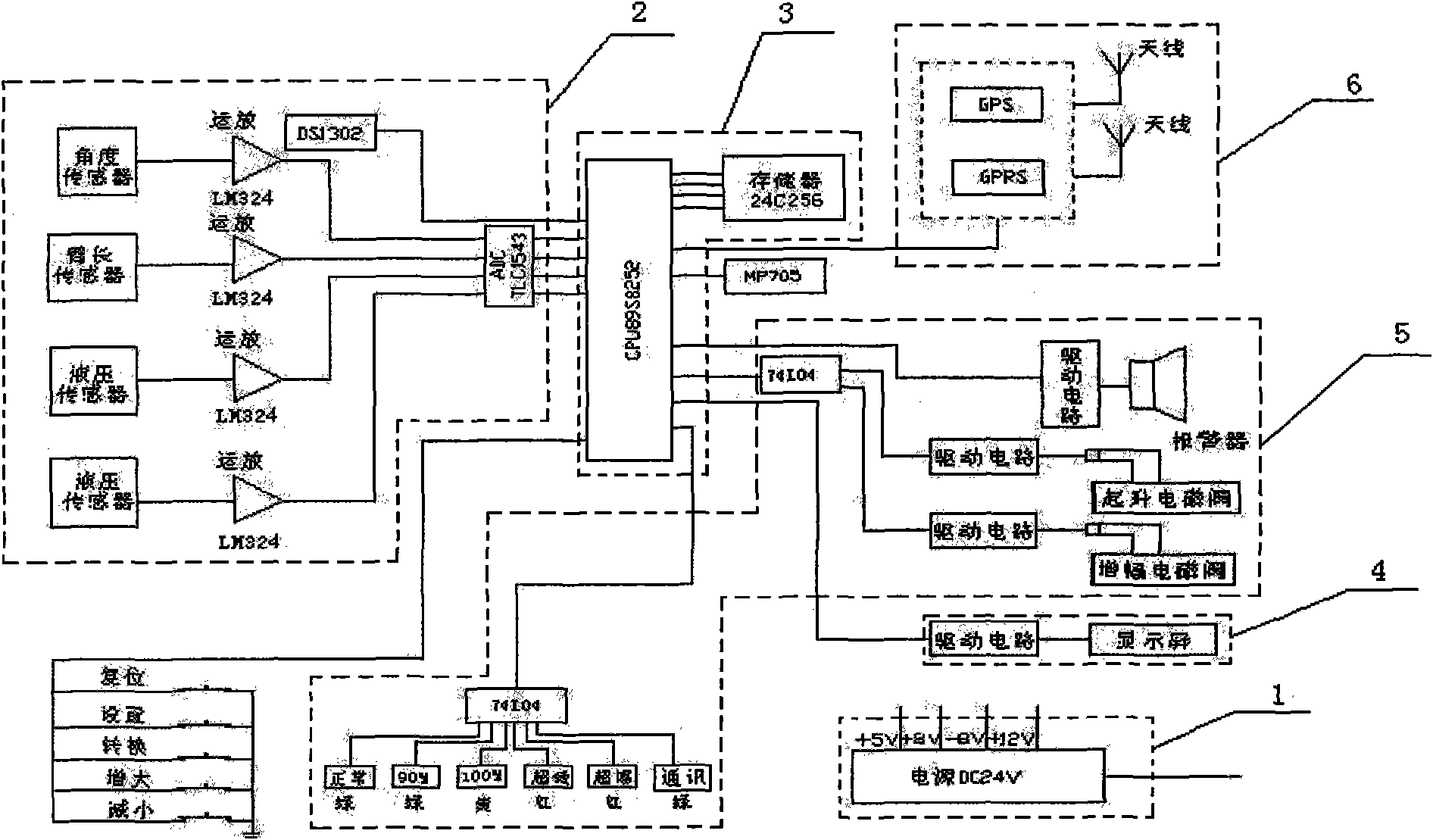

[0024] Such as figure 1 with figure 2 As shown, the present invention includes a power supply module 1, which also includes a data acquisition module 2, a data processing module 3, a data display module 4, a control module 5 and a remote monitoring and maintenance module 6, in which:

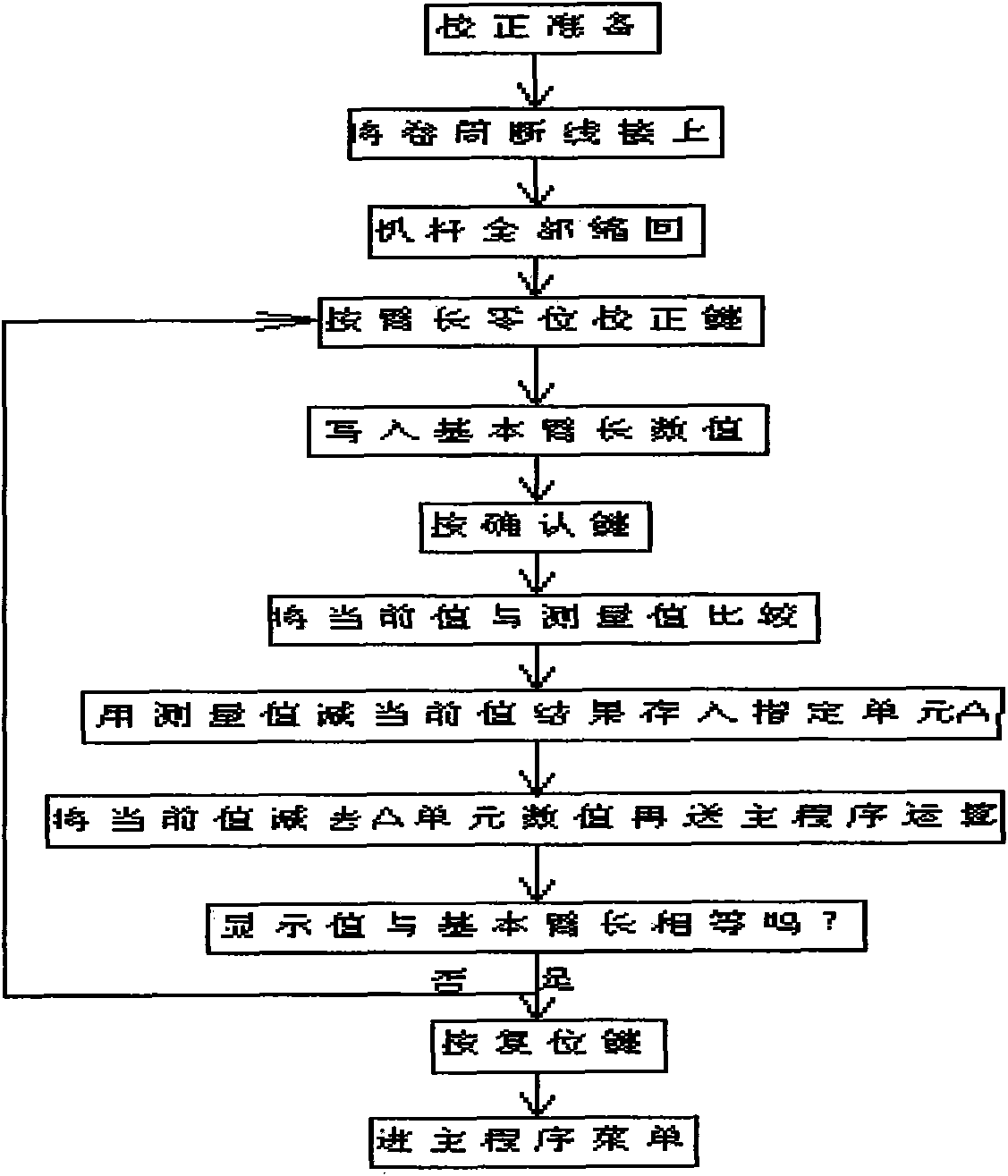

[0025] In the data acquisition module 2, the hydraulic sensors, angle sensors and boom length sensors respectively installed in the corresponding parts of the crane are connected to the input circuit. The hydraulic sensors and boom length sensors can be manually adjusted to realize zero self-tuning;

[0026] In the data processing module 3, the single-chip microcomputer is connected with the memory, the single-chip microcomputer is connected with the input circuit, and the data processing and control programs are stored in the memory;

[0027] In the control module 5, the controller is connected with the single-chip microcomputer through the output circuit, and the alarm is connected with the single-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com