Preparation method of mesoporous composite taking chelate surfactant as template

A surfactant and composite technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of long period, uneven particle distribution, and complex reaction equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At 42°C, 0.127g (0.435mmol) Ni(NO 3 ) 2 ·6H 2 O was added to 40 mL of 0.027 mol / L sodium N-dodecylethylenediaminetriacetate solution and stirred vigorously for 2 hours to form a uniform and stable blue solution. The pH of the system was adjusted to 6 with 0.1 mol / L hydrochloric acid solution, and the stirring was continued for 2 hours.

[0030] Add 0.523g (2.92mmol) 3-aminopropyltrimethoxysilane to the aqueous chelate system, and when the color of the solution starts to turn white, quickly add 0.90g (4.32mmol) tetraethyl orthosilicate, and stir for 3 minutes.

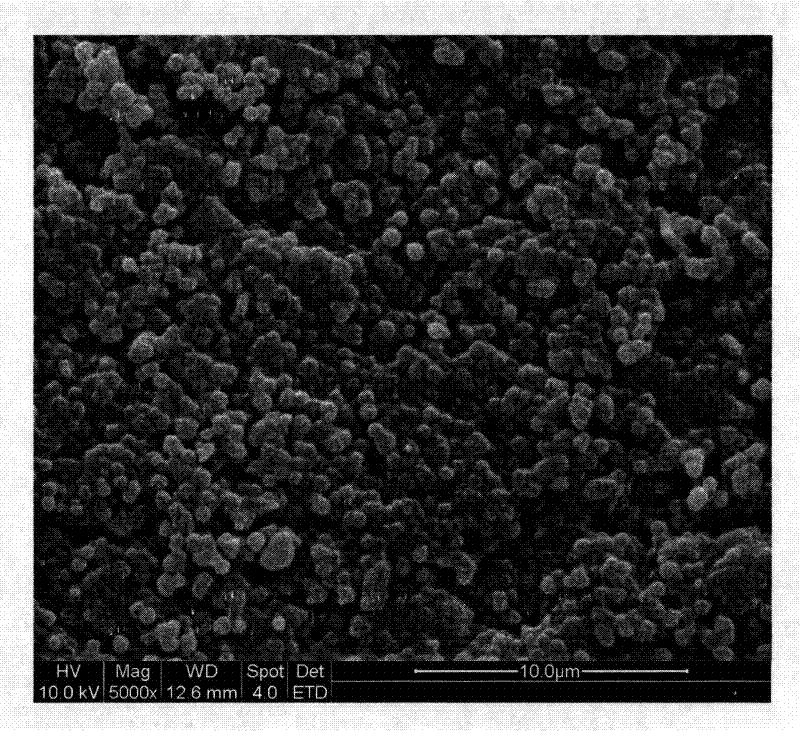

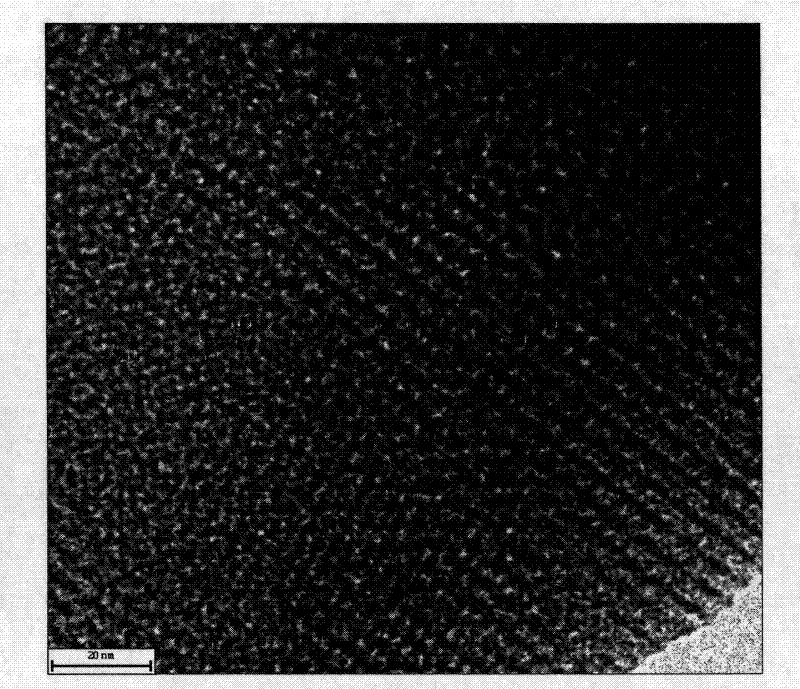

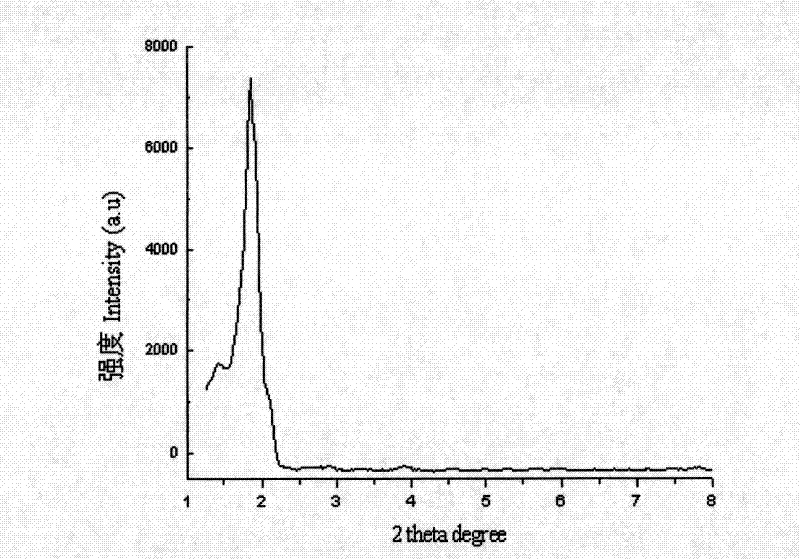

[0031] The reaction bottle was taken out and aged at room temperature for 48 hours, then the precipitate was filtered and washed with deionized water until the washing liquid was neutral. The precipitate was collected and dried, and the resulting product was calcined in a muffle furnace at 560 °C for 5 hours to obtain NiO / SiO 2 mesoporous complex.

Embodiment 2

[0033] At 45°C, 0.208g (0.872mmol) Co(Cl) 2 ·6H 2 O was added to 40 mL of 0.027 mol / L sodium N-tetradecyl ethylenediamine triacetate solution, and stirred vigorously for 2 hours to form a uniform and stable lavender-red solution. The pH value of the system was adjusted to 6.8 with 0.1 mol / L NaOH solution, and the stirring was continued for 2 hours.

[0034] Add 0.581g (3.24mmol) 3-aminopropyltrimethoxysilane to the chelate solution system, and when the color of the solution starts to turn white, quickly add 1.12g (5.39mmol) tetraethyl orthosilicate, and stir for 3 minutes.

[0035] The reaction bottle was taken out and aged at room temperature for 64 hours, then the precipitate was filtered and washed with deionized water until the washing liquid was neutral. The precipitate was collected and dried, and the resulting product was calcined in a muffle furnace at 580 °C for 6 hours to obtain Co 3 o 4 / SiO 2 mesoporous complex.

Embodiment 3

[0037] At 48°C, 0.063g (0.217mmol) Ni(NO 3 ) 2 ·6H 2 O with 0.052g (0.218mmol) Co(Cl) 2 ·6H 2 O was added to 40 mL of 0.027 mol / L sodium N-hexadecyl ethylenediamine triacetate solution and stirred vigorously for 2 hours to form a uniform and stable dark blue solution. The pH value of the system was adjusted to 6.5 with 0.1 mol / L hydrochloric acid solution, and the stirring was continued for 2 hours.

[0038] Add 0.542g (3.02mmol) 3-aminopropyltrimethoxysilane to the chelate solution system, and when the color of the solution starts to turn white, quickly add 1.01g (4.86mmol) tetraethyl orthosilicate, and stir for 3 minutes.

[0039] The reaction bottle was taken out and aged at room temperature for 72 hours, then the precipitate was filtered and washed with deionized water until the washing liquid was neutral. The precipitate was collected and dried, and the resulting product was calcined in a muffle furnace at 600 °C for 7 hours to obtain NiO-Co 3 o 4 / SiO 2 mesoporou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com