Method for preparing nano-silica with controllable particle size

A nano-silica, particle size technology, applied in the field of nano-silica preparation, can solve the problems of low purity, large particle radius, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation of PAMAM template

[0025] 1. Preparation of 0.5-generation PAMAM: Put 120g of methyl acrylate and 10g of methanol in a 400mL volumetric flask, stir magnetically at 5°C, pass He protection for 1h, and add 10.5g of ethylenediamine and 27.5g of methanol with a dropping funnel. The mixture was added dropwise for 1h and passed through He. After the addition, the reaction was carried out at room temperature for 36h. Use a rotary evaporator to distill under reduced pressure (approximately 140Pa, 40°C) to remove unreacted methyl acrylate and methanol to obtain a slightly yellow and slightly viscous liquid.

[0026] 2. Preparation of 1.0-generation PAMAM: Put 84g of ethylenediamine and 11g of methanol in a 500mL volumetric flask, stir magnetically at 5°C, pass He protection for 1h, and add 20g of 0.5-generation PAMAM and 64g of methanol with a dropping funnel. The mixture was added dropwise for 2h and passed through He. After the addition was completed, reacted for 36h ...

Embodiment 1

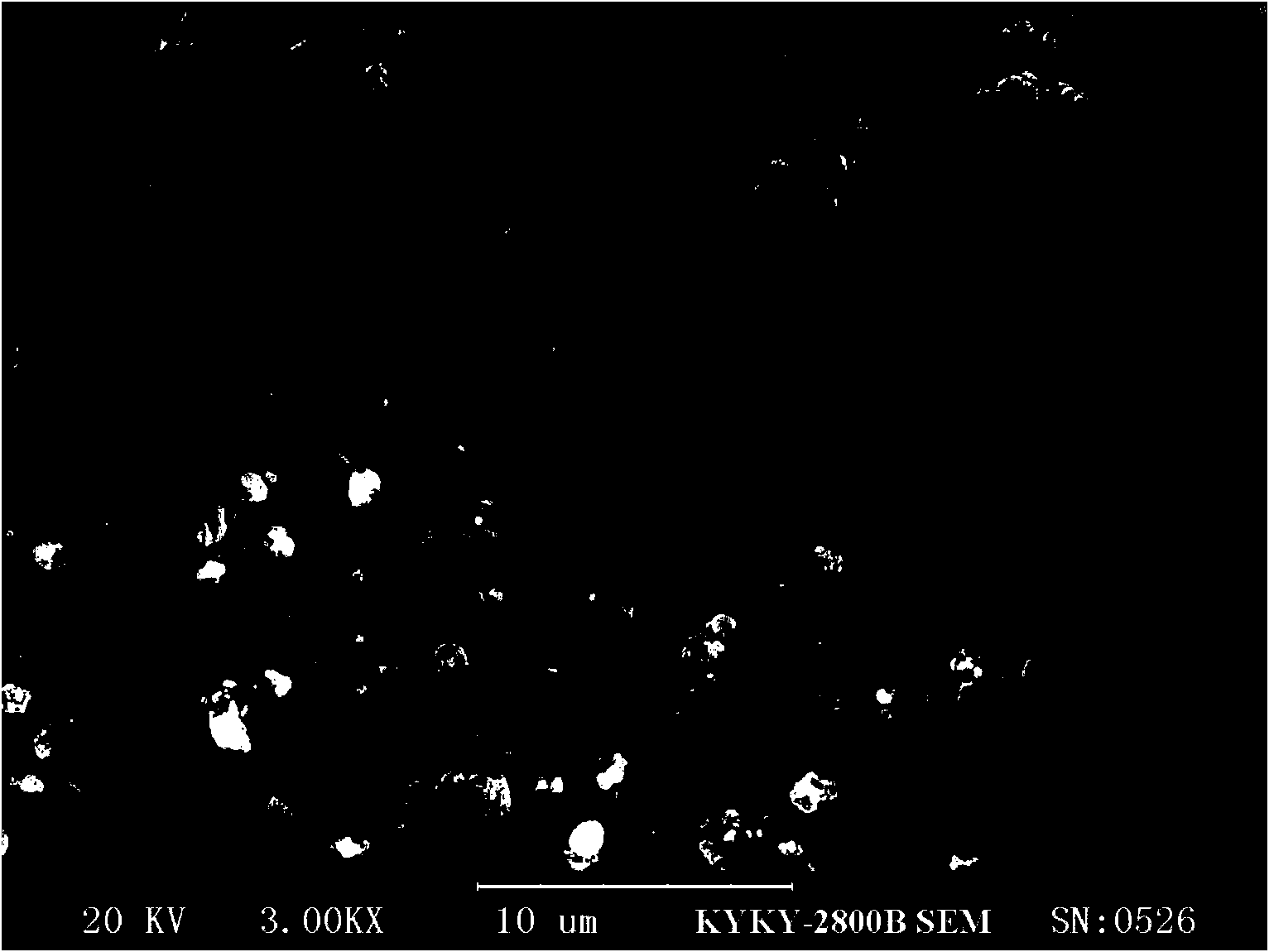

[0036] Example 1: Using 6.0 generation PAMAM as a template to prepare nano-silica, its primary particle size is between 500-650nm and the specific surface area is 11.8-6.9m 2 / g.

[0037] Preparation of nano-particle silica

[0038] Nano SiO 2 The main steps of the preparation:

[0039] 1. Put 100g of the prepared 6.0-generation PAMAM into a 350g mixed solvent of water and methanol, and dissolve it in a closed container (the ratio of water to methanol is 1:3, and the water should be heated at 35℃) , The dissolution time is 30min, use analytically pure ammonia and dilute hydrochloric acid to adjust the pH value to 8-9, as the base fluid for use.

[0040] 2. Add 150g of 28% potassium water glass to the mixed base solution at a rate of 150 drops per minute, and use dilute hydrochloric acid to adjust the pH of the solution at 6~7. Stir and add for 0.5 hours. After that, keep stirring for 1h;

[0041] 3. Filter the resulting precipitate, wash it with a mixed solvent of water and methanol (...

Embodiment 2

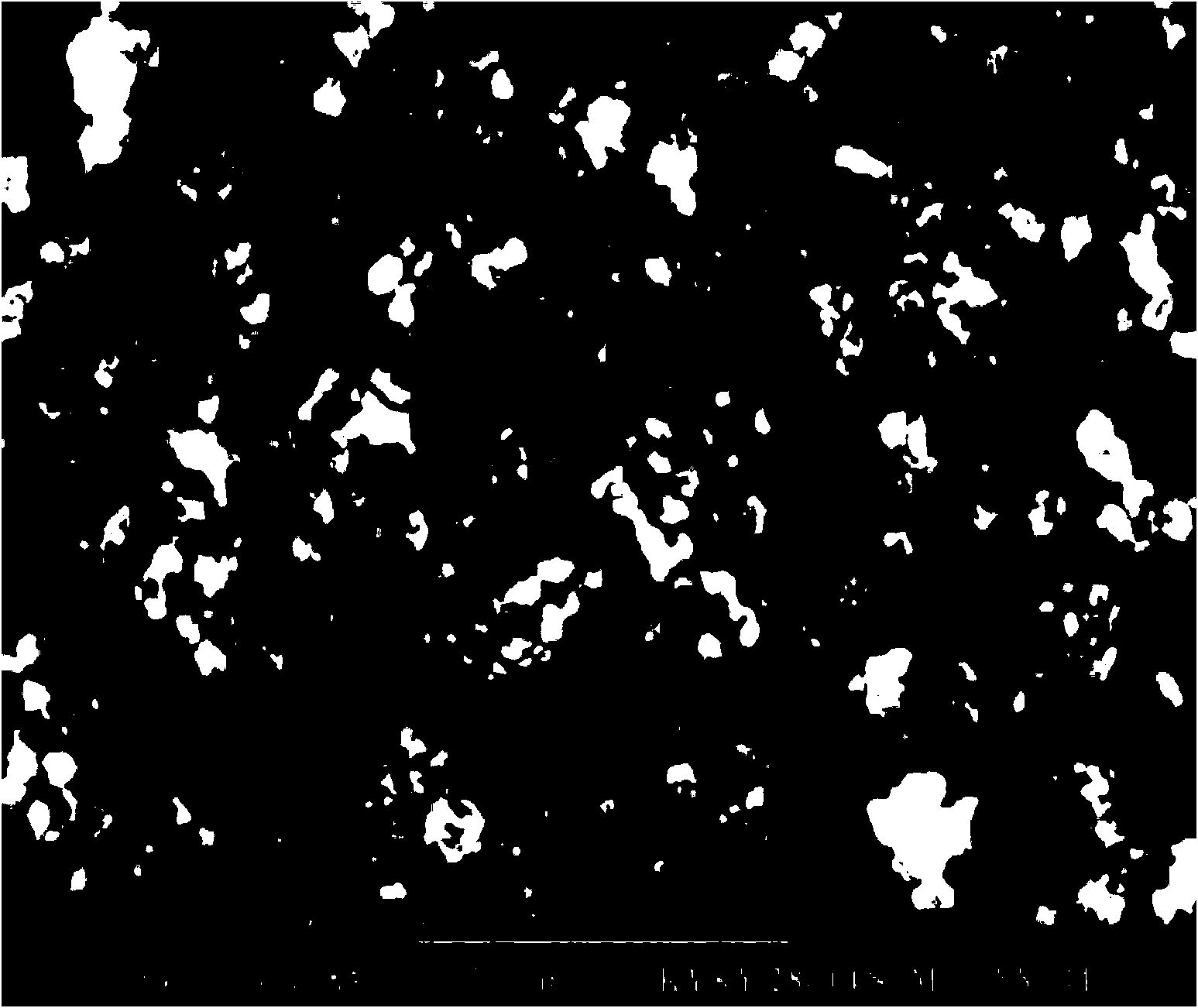

[0045] Example 2: The steps for preparing nano-silica with 4.0-generation PAMAM as a template are the same as above. Its primary particle size is between 560~770nm, and the specific surface area is between 10.2~5.3m 2 / g, SiO prepared 2 High purity, uniform particle size distribution, single particle size, no hard agglomeration, and extremely high practical value.

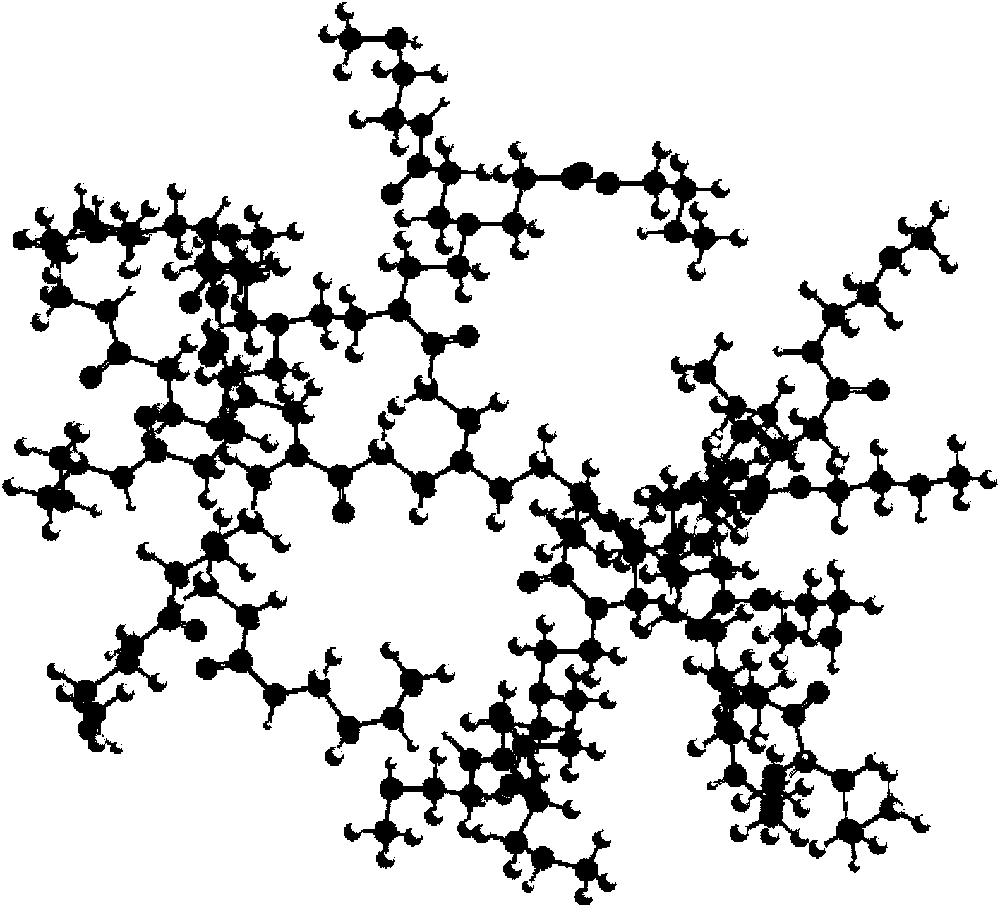

[0046] 1. Prepare the prepared 4.0 generation PAMAM (for molecular structure, please refer to figure 1 ) 100g, put it into 350g of mixed solvent of water and methanol, and dissolve in a closed container (the ratio of water to methanol is 1:3, and the water should be hot water at 35℃), the dissolution time is 30min, use analysis Adjust the pH value to 8-9 with pure ammonia water and dilute hydrochloric acid, and use it as a base liquid.

[0047] 2. Add 150g of 28% potassium water glass to the mixed base solution at a rate of 150 drops per minute, and use dilute hydrochloric acid to adjust the pH of the solution at 6~7. S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com