A kind of macromolecule anion-nonionic emulsifier and preparation method thereof

A non-ionic, non-ionic reactive technology, applied in the field of macromolecular anion-nonionic emulsifiers and their preparation, can solve the problems of easy migration of small molecule emulsifiers and affect the performance of paint films, etc., to achieve good emulsification effect, The effect of high emulsifying ability and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

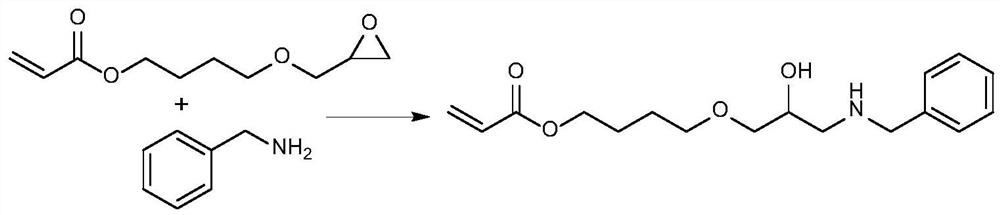

Method used

Image

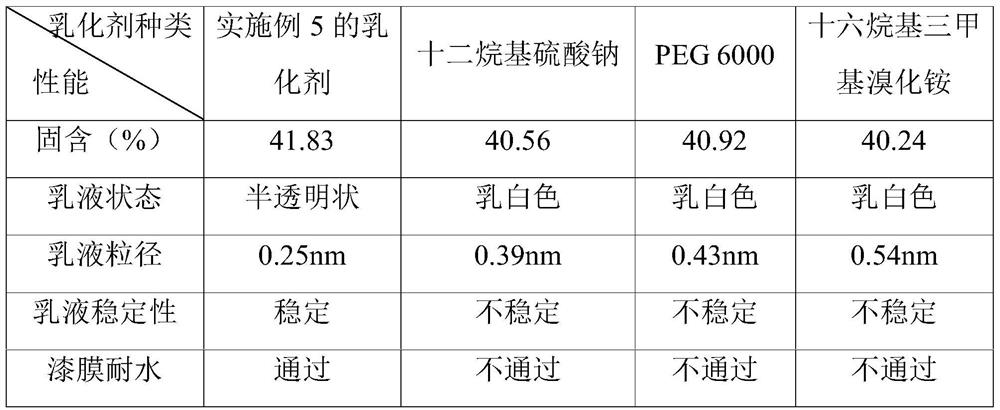

Examples

Embodiment 1

[0036] Example 1: 15 g vinyl monomers (8 g methyl methacrylate, 10 g butyl acrylate), 6 g hydroxyl reactive monomers, 9 g nonionic monomers (vinyl pyrrolidone), 18 g organic acid reactive monomers body (acrylic acid), 4g initiator (di-tert-butyl peroxide), 20g neutralizer (dimethylethanolamine), and the rest are solvent (ethylene glycol butyl ether), totaling 100g.

Embodiment 2

[0037] Example 2: 15g vinyl monomers (5g methyl acrylate, 10g butyl methacrylate), 5g hydroxyl reactive monomer, 8g nonionic monomer (1,4 butylene glycol), 18g organic acid quasi-reactive monomer (methacrylic acid), 4g initiator (tert-butyl oxybenzoate), 20g neutralizer (ethanolamine), and the rest are solvent (propylene glycol butyl ether), totaling 100g.

Embodiment 3

[0038] Example 3: 20 g vinyl monomers (11 g methyl acrylate, 9 g isooctyl acrylate), 6 g hydroxyl reactive monomers, 10 g nonionic monomers (acrylamide), 18 g organic acid reactive monomers ( allyl sulfonic acid), 5 g initiator (di-tert-butyl peroxide), 25 g neutralizing agent (triethylamine), and the rest are solvent (dipropylene glycol methyl ether), totaling 100 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com