Preparation method of super-hydrophobic fluorine-containing organic silicon microspheres

A technology of organosilicon microspheres and superhydrophobicity, which is applied in the field of organosilicon materials, can solve the problems such as the difficulty of preparing superhydrophobic microspheres, and achieve the effects of excellent hydrophobicity, good sphericity, and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of superhydrophobic fluorine-containing silicone microspheres in this embodiment comprises the following steps:

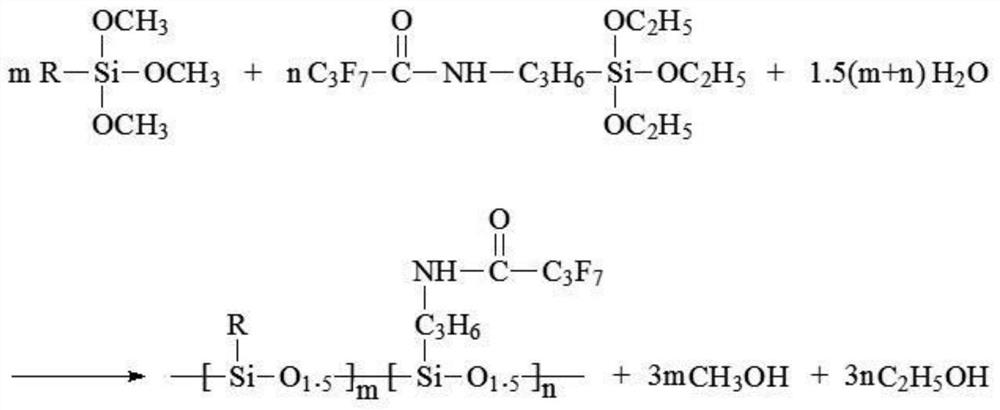

[0026] (1) Mix 5mL of γ-aminopropyltriethoxysilane and 15mL of methyl perfluorobutyrate thoroughly, blow in nitrogen gas, and reflux at 65°C for 12h;

[0027] (2) After the reaction, add 100mL of absolute ethanol and 100mL of perfluorohexane to separate the liquid, take out the lower layer liquid, and obtain perfluorosilane through vacuum distillation;

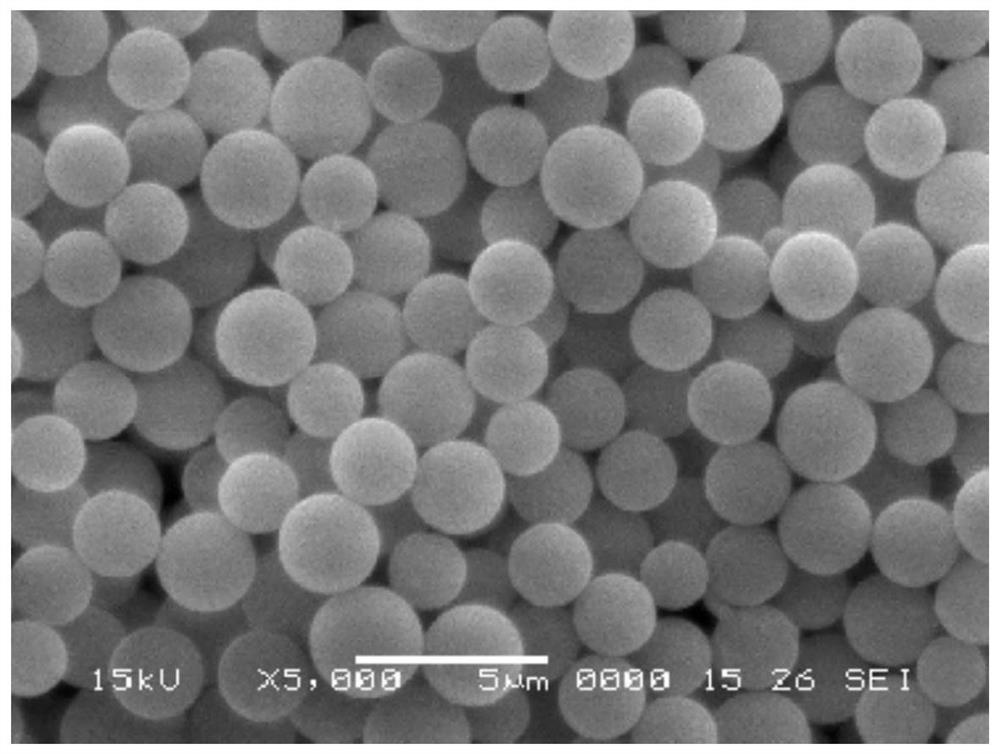

[0028] (3) Mix 10mL perfluorosilane, 30mL methyltrimethoxysilane, 20mL ethanol and 160mL water evenly, then add tetramethylammonium hydroxide to adjust the pH value to 8.5, and react at 50°C for 4 hours to obtain superhydrophobic fluorine-containing Silicone microspheres with a particle size of 2.9 μm, such as figure 1 As shown, it can be seen that the superhydrophobic fluorine-containing silicone microspheres prepared in this example have a single particle size, good sphericity, a yi...

Embodiment 2

[0030] The preparation method of superhydrophobic fluorine-containing silicone microspheres in this embodiment comprises the following steps:

[0031] (1) Fully mix 5mL of γ-aminopropyltriethoxysilane and 10mL of methyl perfluorobutyrate, blow in nitrogen gas, and reflux at 65°C for 12h;

[0032] (2) After the reaction, add 100mL of absolute ethanol and 100mL of perfluorohexane to separate the liquid, take out the lower layer liquid, and obtain perfluorosilane through vacuum distillation;

[0033] (3) Mix 10mL perfluorosilane, 30mL methyltrimethoxysilane, 20mL ethanol and 160mL water evenly, then add tetramethylammonium hydroxide to adjust the pH value to 8.5, and react at 50°C for 4 hours to obtain superhydrophobic fluorine-containing Silicone microspheres, the particle size is 3.2 μm, and the yield is 89%.

Embodiment 3

[0035] The preparation method of superhydrophobic fluorine-containing silicone microspheres in this embodiment comprises the following steps:

[0036] (1) Fully mix 5mL of γ-aminopropyltriethoxysilane and 10mL of methyl perfluorobutyrate, blow in nitrogen gas, and reflux at 65°C for 12h;

[0037] (2) After the reaction, add 100mL of absolute ethanol and 100mL of perfluorohexane to separate the liquid, take out the lower layer liquid, and obtain perfluorosilane through vacuum distillation;

[0038] (3) Mix 10mL perfluorosilane, 40mL phenyltrimethoxysilane, 30mL ethanol and 160mL water evenly, then add tetramethylammonium hydroxide to adjust the pH value to 8.5, and react at 50°C for 4 hours to obtain superhydrophobic fluorine-containing Silicone microspheres, the particle size is 3.8 μm, and the yield is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com