A kind of pesticide sustained-release microsphere and preparation method thereof

A technology for slow-release microspheres and pesticides, applied in the field of pesticides, can solve the problems of fast drug release rate and low drug entrapment rate, and achieve the effects of improving slow-release performance, expanding control spectrum and reducing pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

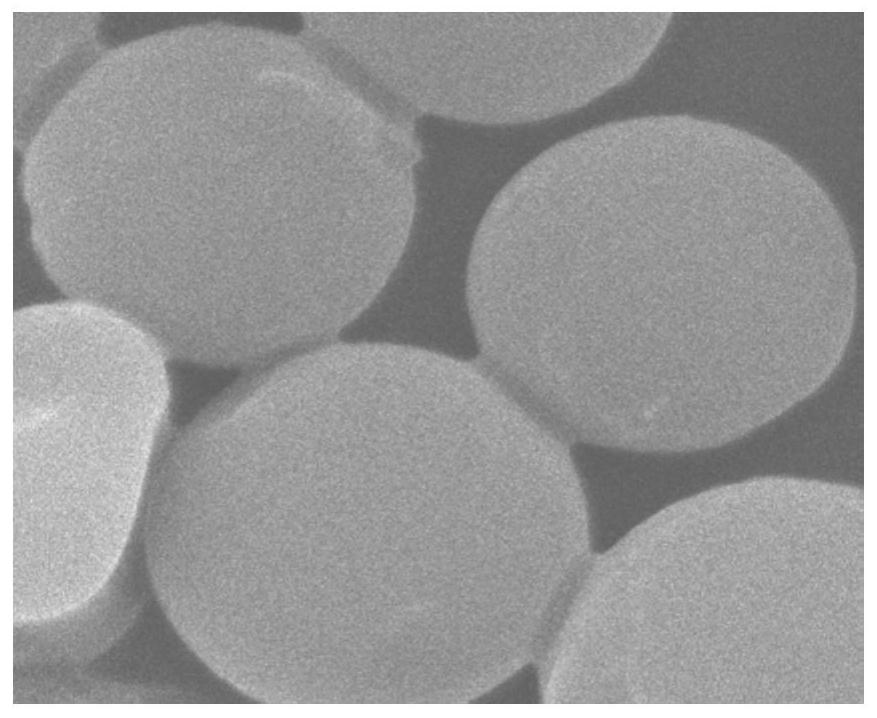

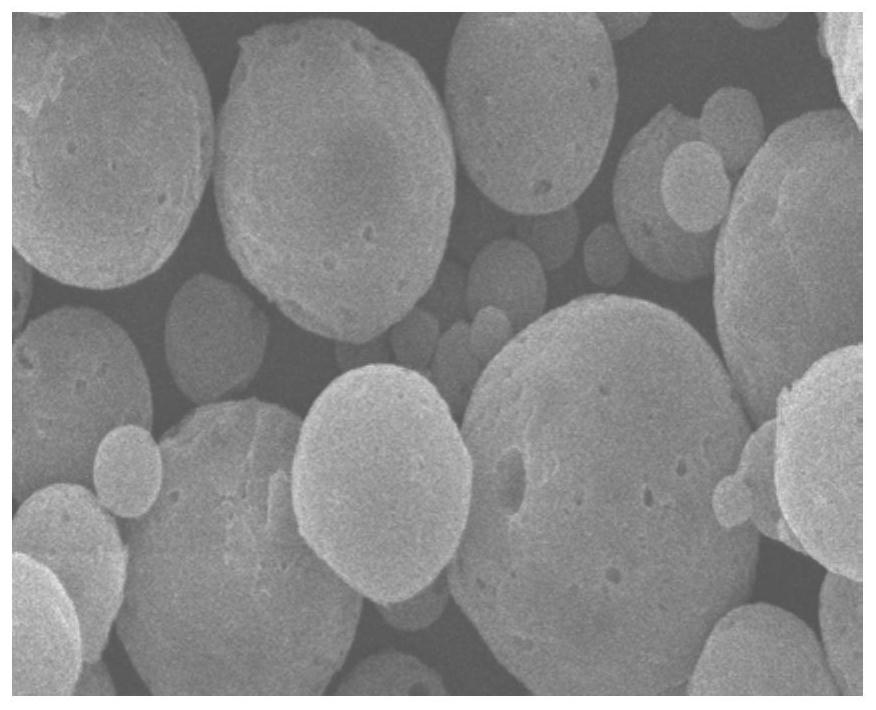

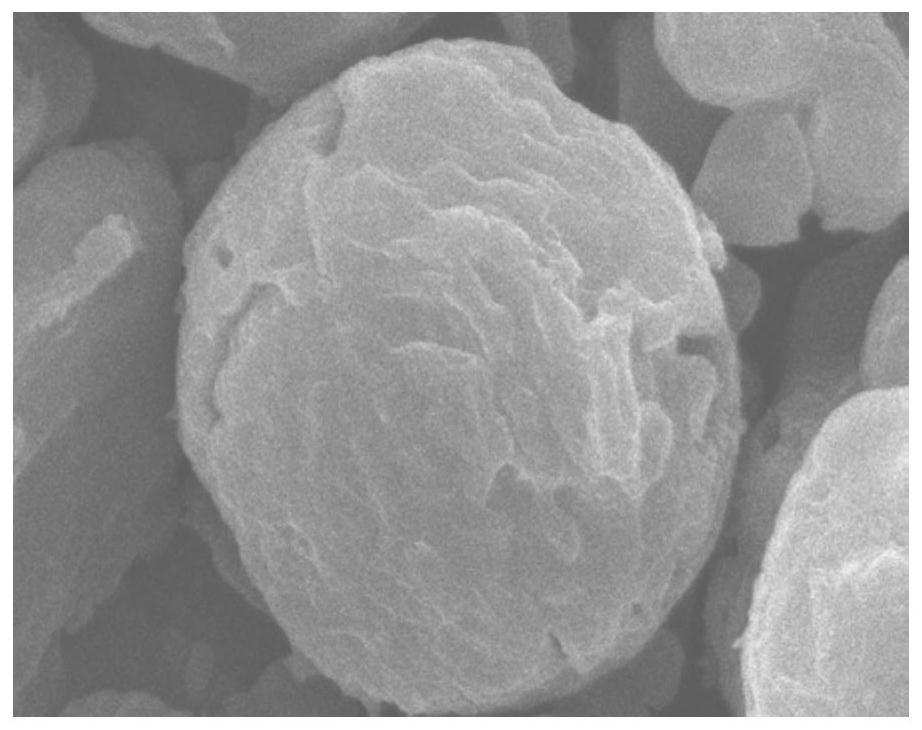

Image

Examples

Embodiment 1

[0026] 1) Preparation of drug-containing and carrier oil phase: 0.4g azoxystrobin, 0.25g difenoconazole pesticide technical, 1.365g polybutylene succinate, 0.585g polylactic acid were dissolved in 30ml dichloride In methane, obtain the mixed liquid oil phase containing medicine and carrier; (the weight-average molecular weight of polylactic acid is 140,000, and the weight-average molecular weight of polybutylene succinate is 150,000)

[0027] (2) Preparation of the aqueous phase of the emulsified dispersant: preparing an aqueous polyvinyl alcohol solution with a mass fraction of 25 mg / ml as the aqueous phase;

[0028] (3) Add 30ml of the mixed liquid oil phase in step (1) to the 90ml water phase in step (2), and cut at 6000rpm for 3min at room temperature to obtain an oil-in-water emulsion; The oil-in-emulsion was stirred at a speed of 600 rpm until the dichloromethane solvent was completely volatilized, centrifuged three times at a speed of 10,000 rpm for 7 minutes each time,...

Embodiment 2

[0041] (1) Preparation of drug-containing and carrier oil phase: 0.4 g of azoxystrobin, 0.25 g of difenoconazole pesticide technical, 1.755 g of polybutylene succinate, and 0.195 g of polylactic acid were dissolved in 30 ml of difenoconazole In methyl chloride, the mixed liquid oil phase containing medicine and carrier is obtained; (the weight-average molecular weight of polylactic acid is 100,000, and the weight-average molecular weight of polybutylene succinate is 200,000)

[0042] (2) Preparation of the aqueous phase of the emulsified dispersant: preparing an aqueous polyvinyl alcohol solution with a mass fraction of 15 mg / ml as the aqueous phase;

[0043] (3) Add 30ml of the mixed liquid oil phase in step (1) to the 60ml water phase in step (2), and cut it at 7000rpm for 4min at room temperature to obtain an oil-in-water emulsion at a reaction temperature of 35°C. The oil-in-emulsion was stirred at 800 rpm until the organic solvent evaporated completely, centrifuged three ...

Embodiment 3

[0046] (1) Preparation of drug-containing and carrier oil phase: 0.4 g of azoxystrobin, 0.25 g of difenoconazole pesticide technical, 0.975 g of polybutylene succinate, and 0.975 g of polylactic acid were dissolved in 30 ml of difenoconazole In methyl chloride, the mixed liquid oil phase containing medicine and carrier is obtained; (the weight-average molecular weight of polylactic acid is 200,000, and the weight-average molecular weight of polybutylene succinate is 150,000)

[0047] (2) Preparation of the aqueous phase of the emulsified dispersant: preparing an aqueous polyvinyl alcohol solution with a mass fraction of 22 mg / ml as the aqueous phase;

[0048] (3) Add 30ml of the mixed liquid oil phase in step (1) to 150ml of the water phase in step (2), and cut at 8000rpm for 5min at room temperature to obtain an emulsion; at 35°C, stir the emulsion at a speed of 400rpm , until the organic solvent is completely evaporated, centrifuged at 6000rpm three times for 10min each time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com