Method of thick mash alcohol fermentation by using fresh cassava

A technology of alcohol fermentation and fresh cassava, applied in fermentation, biofuel, etc., can solve the problems of low mass transfer efficiency, high viscosity of feed liquid, and poor fluidity, so as to improve mass transfer efficiency, reduce labor productivity, and have good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

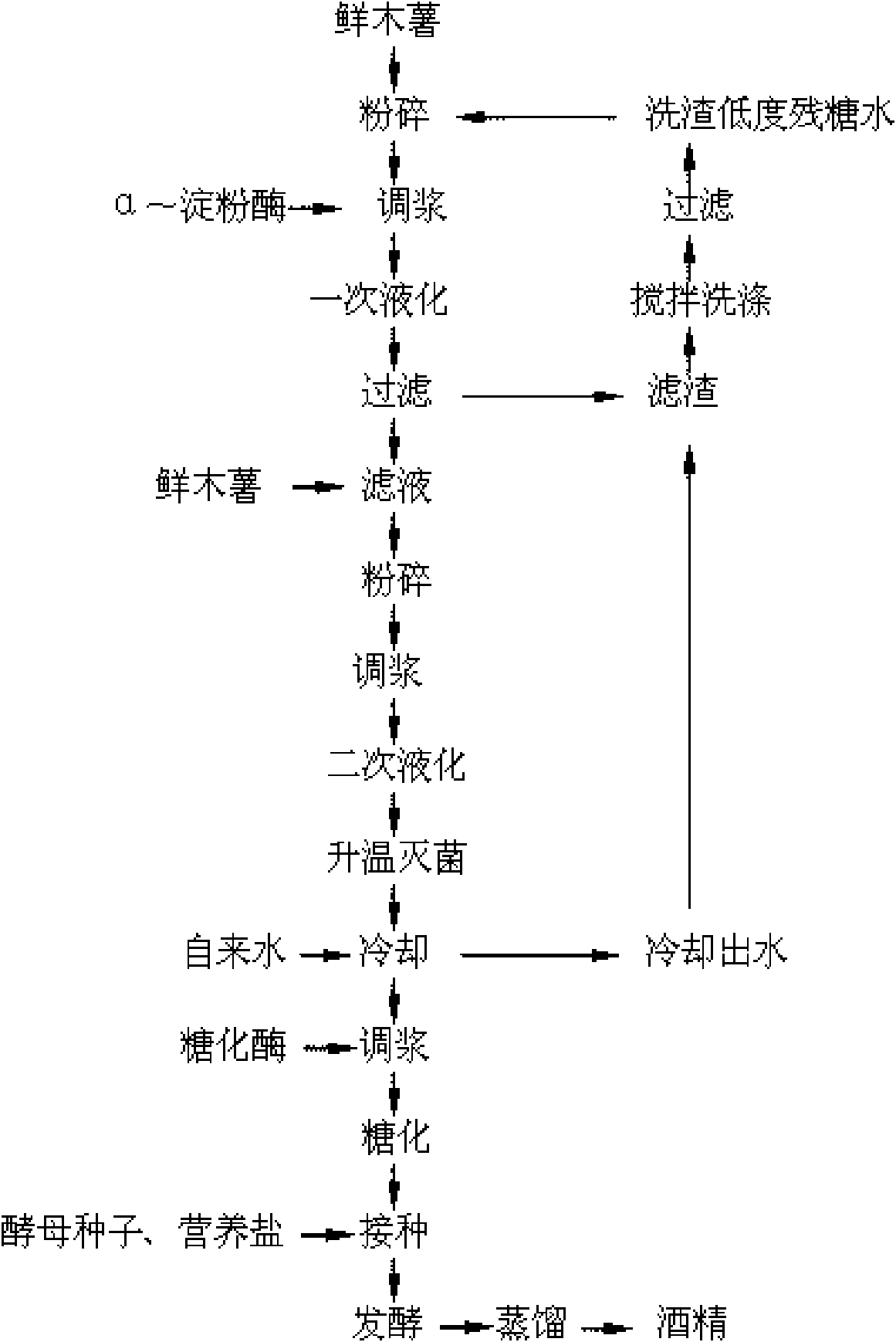

Image

Examples

Embodiment

[0021] A method for alcohol fermentation using fresh cassava mash includes the following steps:

[0022] (1) Crushing: mixing fresh cassava and washing residue with low-level residual sugar water in a ratio of 1:1 to crush to make the particle size less than 1.5mm; the dry matter content in the slurry is 15%-17%.

[0023] (2) Sizing: Adjust the pH of the slurry to 5.8-6.5 with an acid-base solution, and add 12u of high-temperature resistant α-amylase per gram of absolutely dry tapioca starch fed during the first crushing.

[0024] (3) Liquefaction and filtration: heat the slurry to 90℃~95℃, keep it for 60min~120min, filter with 80 mesh nylon filter cloth to obtain the filtrate, the liquefied liquid; the dry matter content of the filtrate is above 15%; To recover the residual sugar from the filter residue, add 85°C hot water to the filter residue according to the ratio of filter residue: water = 1:10, stir it evenly, keep it at 85°C~90°C for 10 minutes, and filter. The filtrate obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com