Apparatus for producing a mixture of hydrogen and oxygen

A gas generation system, hydrogen-oxygen technology, applied in electrodes, cells, electrolysis process, etc., can solve the problems of spark backfire and economic decline, and achieve the effect of easy falling off, ensuring economical efficiency, and improving electrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings.

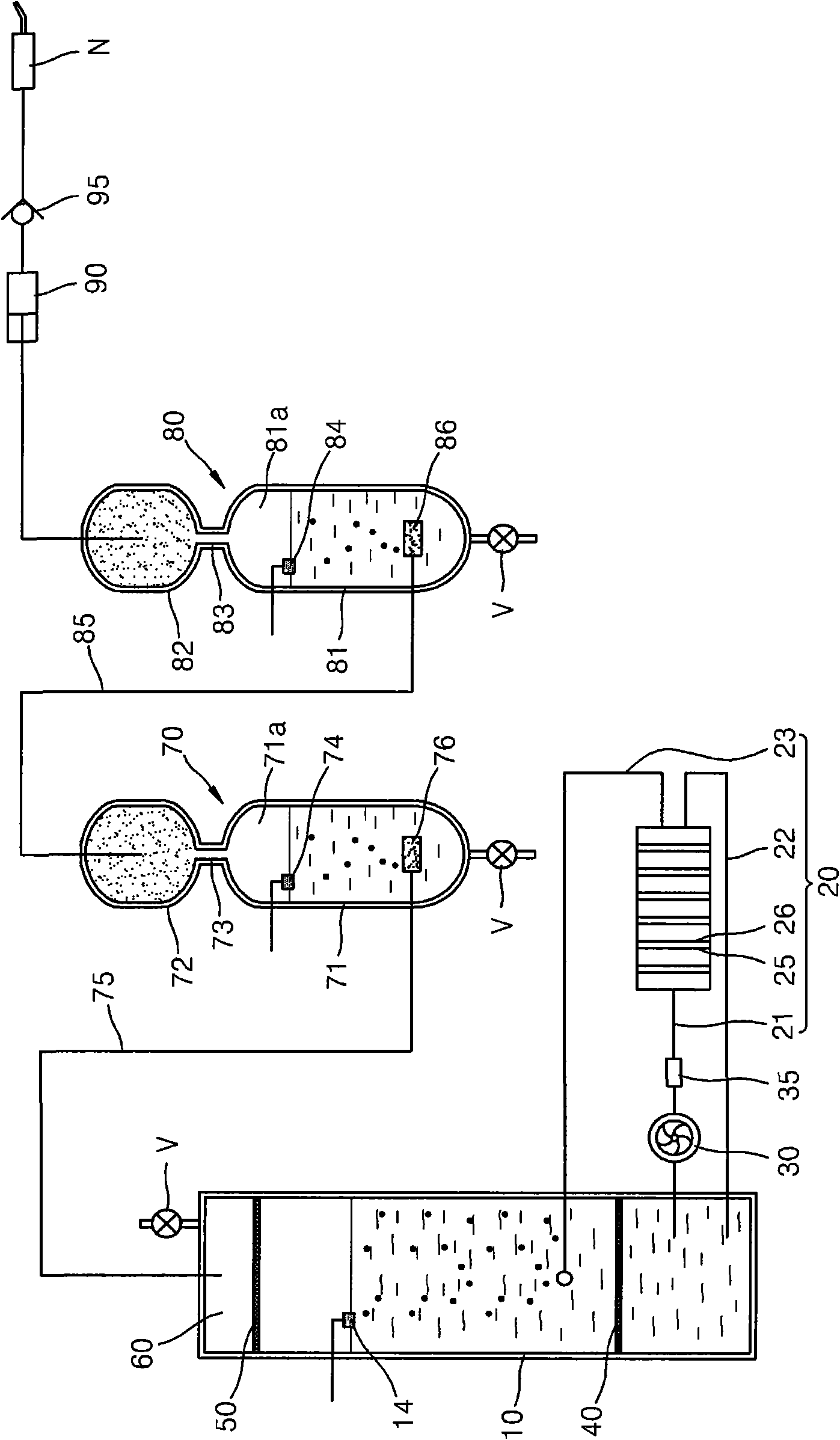

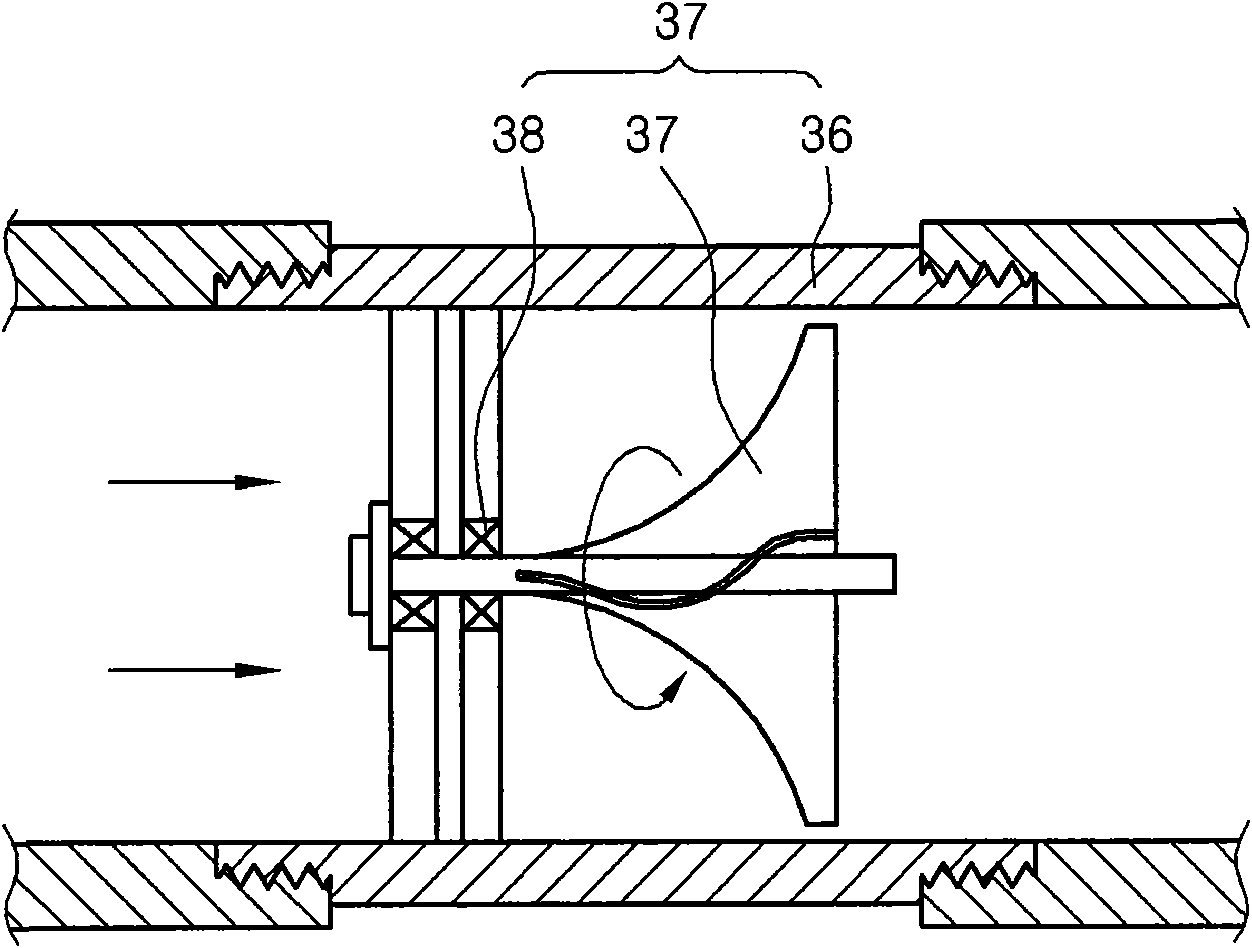

[0038] figure 1 It is a detailed diagram showing the structure of the oxyhydrogen gas generation system of the present invention, figure 2 is displayed figure 1 Detailed diagram of the nanoparticle generation device in .

[0039] As shown in the figure, the oxyhydrogen gas generation system provided by the present invention includes: an electrolyte storage tank 10, an electrode assembly 20, a mixed gas separator 40, a mixed gas separation filter 50, a gas collecting device 60, and a first filter assembly 70 , the second filter assembly 80, the second gas pipeline 85, the anti-backfire device 90 and the nozzle N.

[0040] Wherein the electrolytic solution storage tank 10 is used for storing the electrolytic solution formed by the remaining part after the water is electrolyzed;

[0041] The electrode assembly 20 is composed of a plurality of positive electrodes 25 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com