Breathable fiber with moisture penetrability and preparation method thereof

A fiber and arc technology, which is applied in the field of perspiration and moisture permeable and breathable fibers and their preparation, can solve the problems of airtightness and moisturetightness of hollow fibers, and achieve the effects of sufficient rigidity, good elasticity and hygienic use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1, sweat-conducting, moisture-permeable and breathable fiber

[0014] Raw material: polyethylene terephthalate (intrinsic viscosity 0.65-0.66, melting point 266°C, carboxyl content ≤ 25 equivalents / g x 106, ash content < 0.04%)

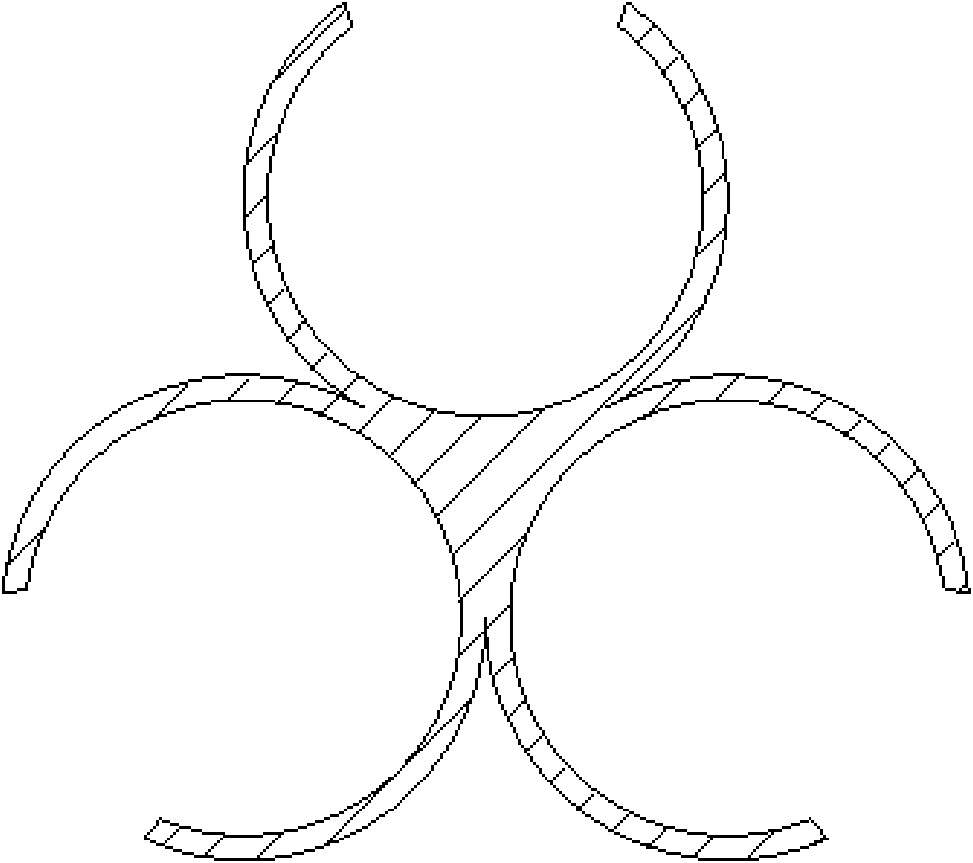

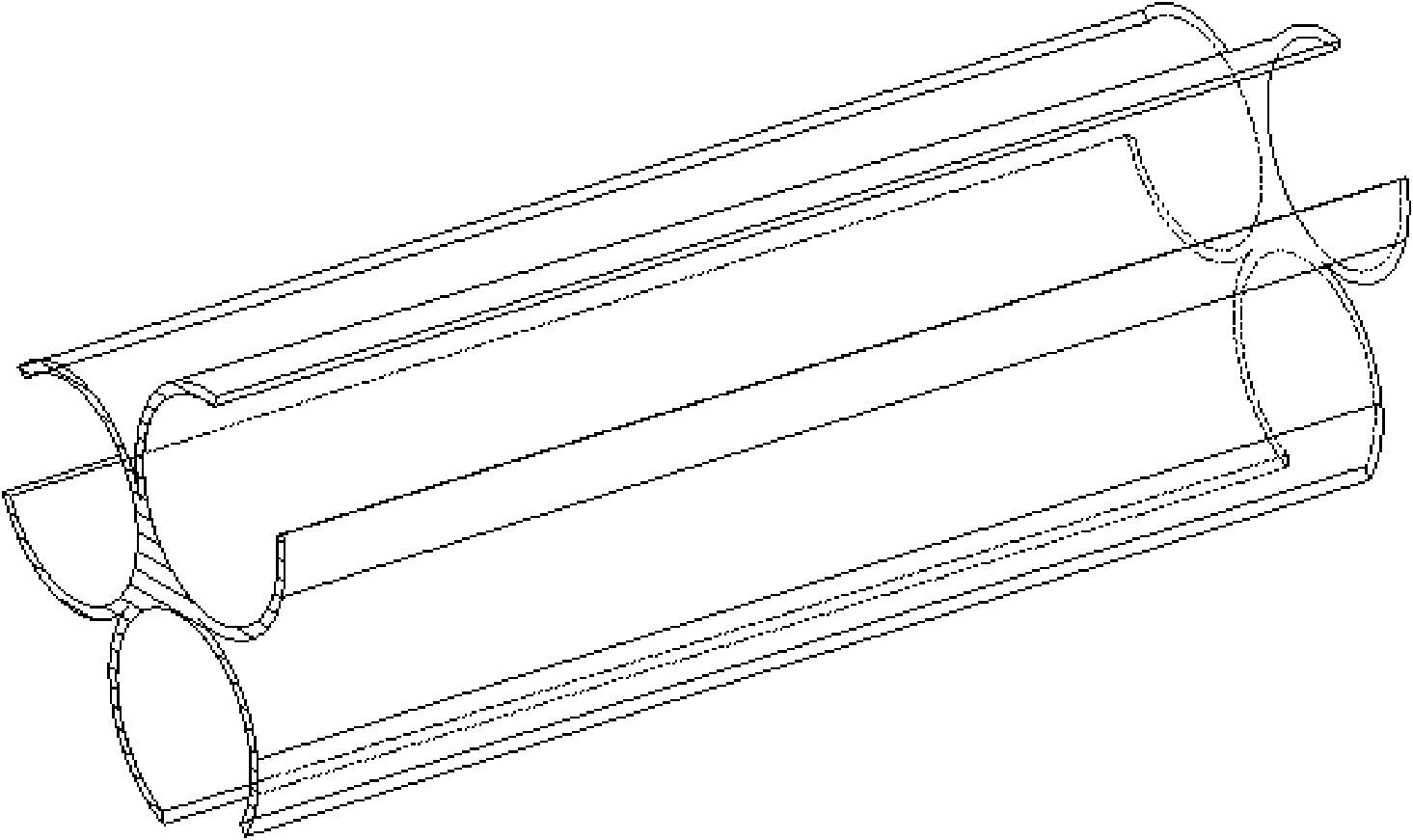

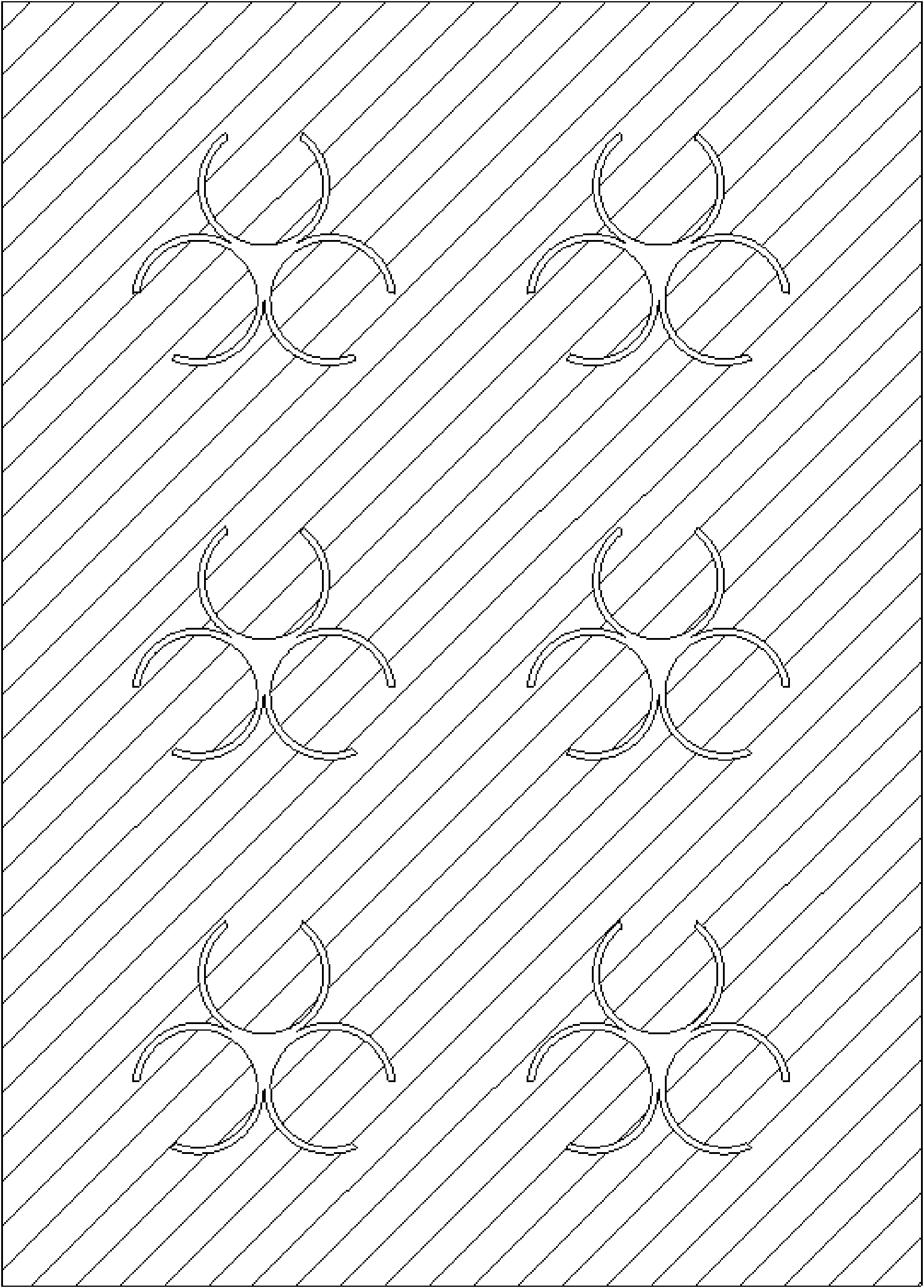

[0015] The polyethylene terephthalate was dried by a drum dryer (at a temperature of 150° C.), and then put into a VD406 short filament melt spinning machine for melt spinning. The raw material is melted at a temperature of 280°C, and then enters the screw extruder for extrusion (the temperature in the 1st zone of the screw is 260°C, the temperature in the 2nd zone of the screw is 270°C, the temperature in the 3rd zone of the screw is 272°C, and the temperature in the 4th zone of the screw is 278°C, the temperature in the 5th zone of the screw is 279°C, and the temperature in the 6th zone of the screw is 280°C), enter the spinning assembly through the melt pipe and spray out from the porous spinneret. image 3 Shown is the schematic...

Embodiment 2

[0016] Embodiment 2, sweat-conducting, moisture-permeable and breathable fiber

[0017] Raw material: polyethylene terephthalate (PETS) (intrinsic viscosity 0.65-0.66, melting point 266°C, carboxyl content ≤ 25 equivalents / g x 106, ash content < 0.04%)

[0018] The polyethylene terephthalate was dried by a drum dryer (at a temperature of 150° C.), and then put into a VD406 short filament melt spinning machine for melt spinning. The raw material is melted at a temperature of 290°C, and then enters the screw extruder for extrusion (the temperature in the 1st zone of the screw is 270°C, the temperature in the 2nd zone of the screw is 280°C, the temperature in the 3rd zone of the screw is 282°C, and the temperature in the 4th zone of the screw is 288°C, the temperature in the 5th zone of the screw is 289°C, and the temperature in the 6th zone of the screw is 290°C), enter the spinning assembly through the melt pipe and spray out from the porous spinneret. image 3 Shown is the sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com