Integral plugged electric-hydraulic control reversing valve with classified filtering function

An electro-hydraulic control reversing valve and graded filtration technology, which is applied in the directions of fluid pressure actuation devices, fluid pressure actuation system components, pillars/supports, etc., can solve the problem of tube filter replacement difficulty, easy secondary pollution, filtration The problem of large size of the filter is eliminated, and the effects of easy disassembly, maintenance and replacement of the filter element, saving the space of the bracket, and simplifying the hydraulic system are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

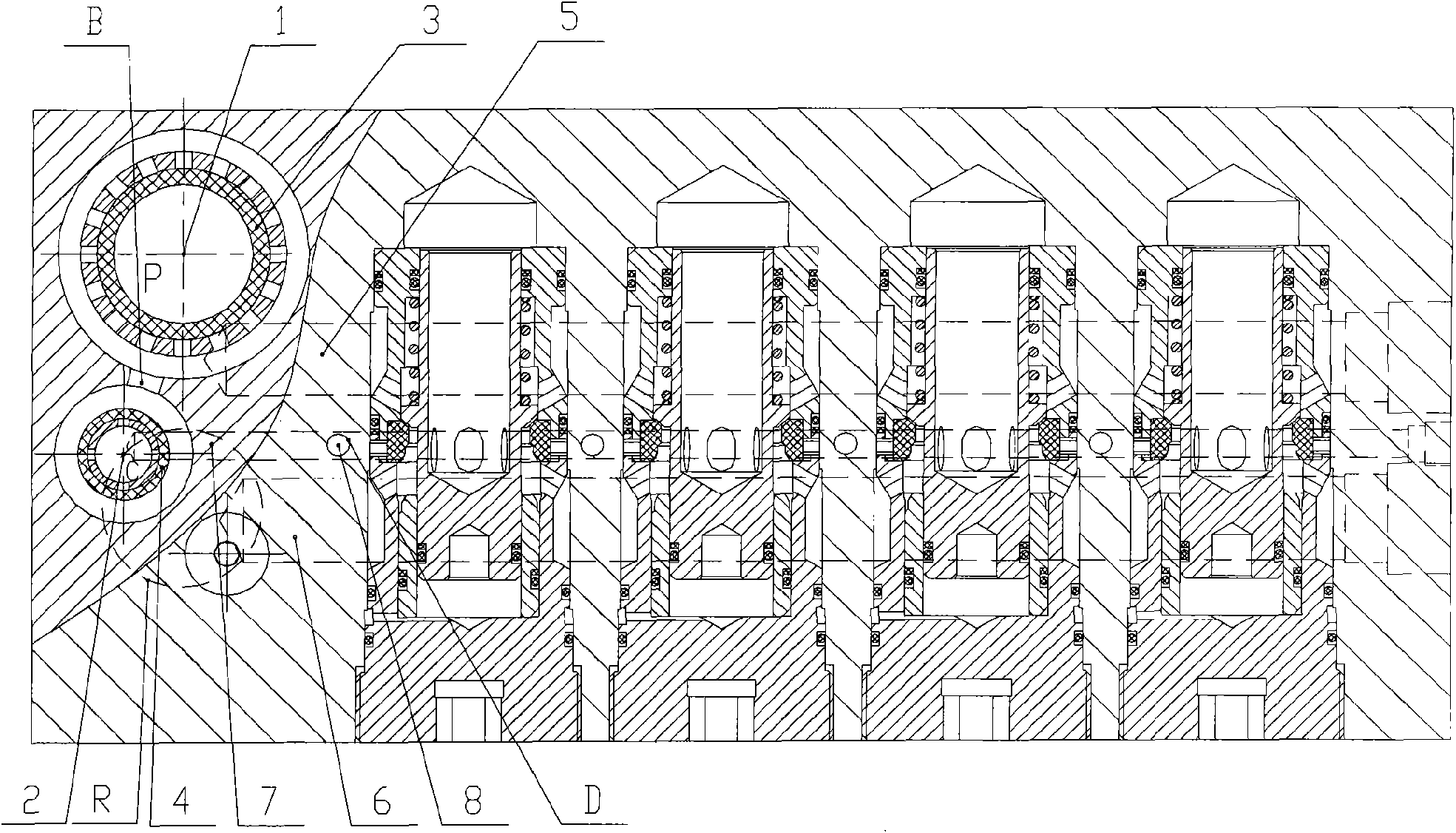

[0016] Such as figure 1 As shown in the figure, a cartridge-type electro-hydraulic control reversing valve with graded filtration includes bracket filter 1, pilot valve filter 2 and reversing valve group, and the filtration accuracy of pilot valve filter 2 is not lower than that of bracket filter 1. , the bracket filter 1 and the pilot valve filter 2 are integrally installed in the reversing valve group through threaded connection; the reversing valve group has a liquid inlet P, a first liquid outlet R and a second liquid outlet D, The liquid inlet P communicates with the bracket filter 1; the liquid inlet P communicates with the channel B, the channel B communicates with the channel C, the channel C communicates with the second liquid outlet D, and the liquid inlet P communicates with the second liquid outlet The bracket filter 1 and the pilot valve filter 2 are installed between the D channels. The liquid inlet of the integral plug-in electro-hydraulic control reversing val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com