Combined type piston of telescopic shock absorber

A shock absorber and combined technology, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of unsuitable shock absorbers, etc., to overcome pitching vibration, improve safety, and attenuate the body The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

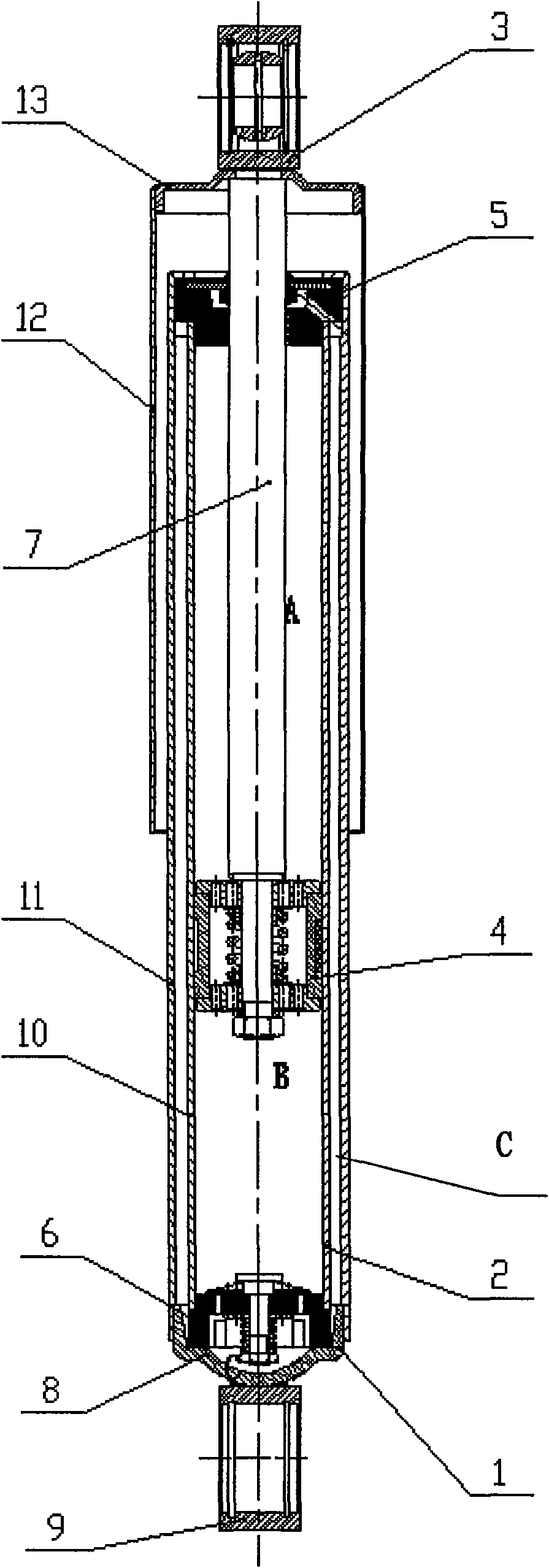

[0021] The following is a detailed description of the assembly method of the military barrel shock absorber in conjunction with the attached drawings:

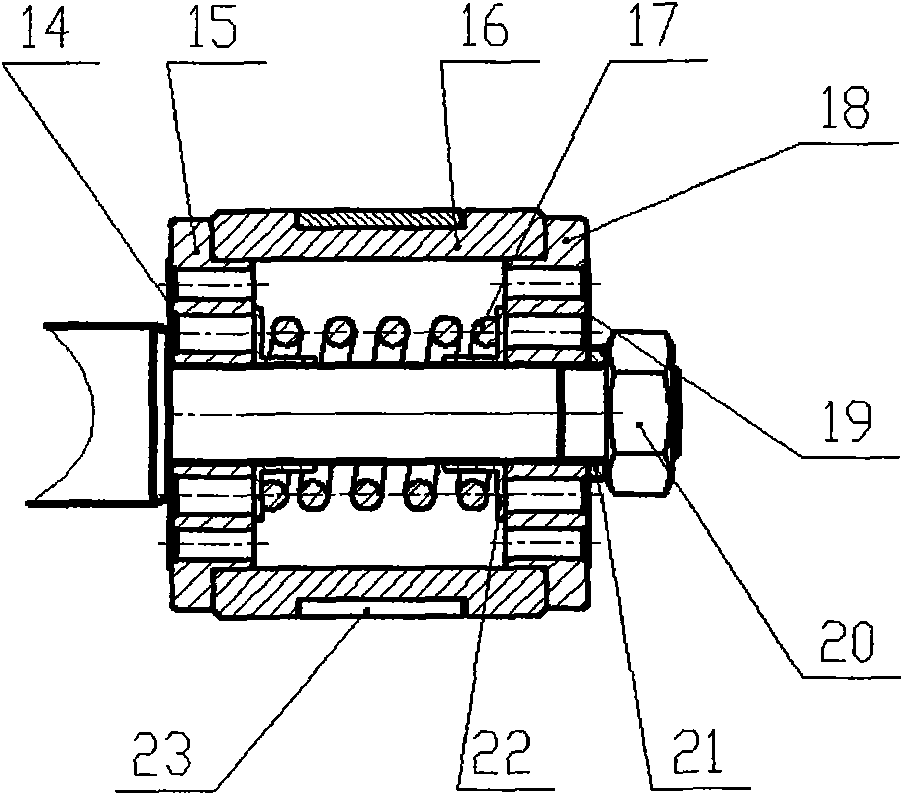

[0022] figure 2 A drawing of the shock absorber piston assembly is shown. According to the sequence of compression valve plate, upper valve plate, piston, piston ring, piston spring seat, piston spring, lower valve plate, recovery valve plate, adjusting gasket and piston tightening nut, assemble the piston assembly on the piston rod welding part On the assembly, the piston rod is then riveted.

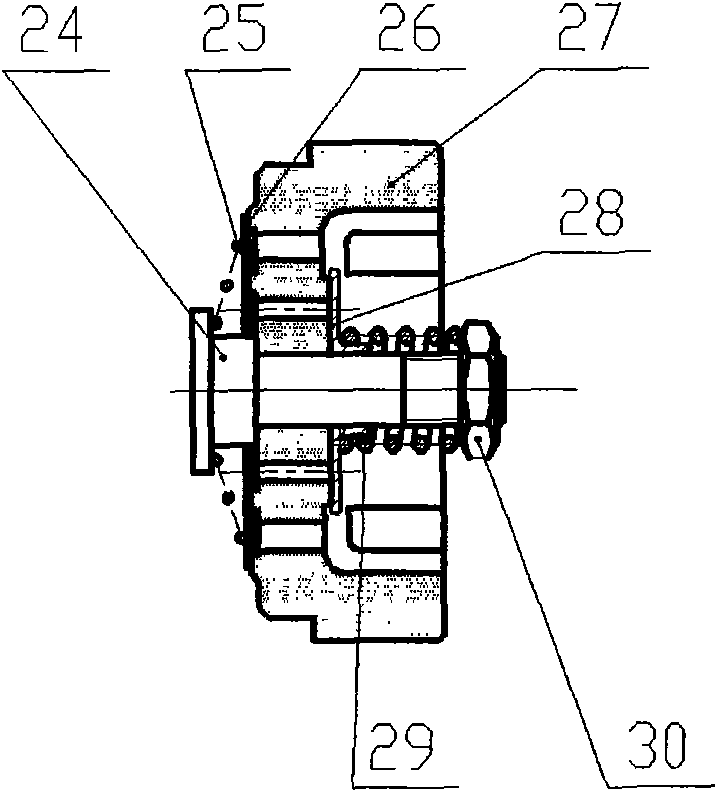

[0023] image 3 As shown in the bottom valve assembly diagram, install the bottom valve screw, compensation valve spring, compensation valve plate, bottom valve seat, safety valve spring seat, safety valve spring, and bottom valve tightening nut in sequence, tighten the nut, and then tighten the bottom valve. When the valve is screw riveted, the assembly of the bottom valve assembly is completed.

[0024] Weld the piston rod, dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com