Measuring method of 3D profilometry of free-form surface based on computer-generated hologram

A technology for calculating holography and three-dimensional topography, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of low manufacturing accuracy, complicated manufacturing process, and long manufacturing cycle, and achieve high measurement accuracy, improved processing technology, The effect of quasi-real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

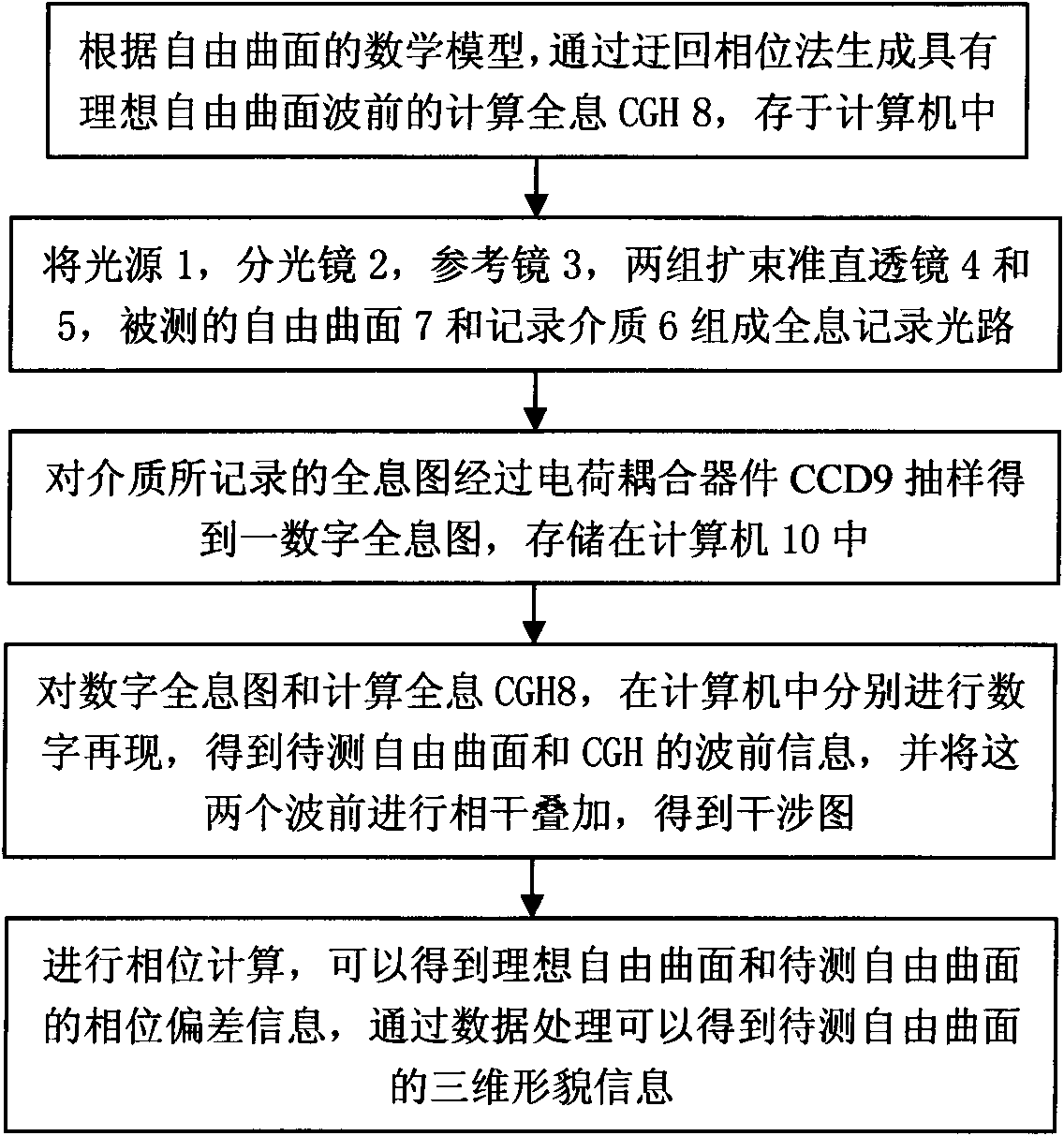

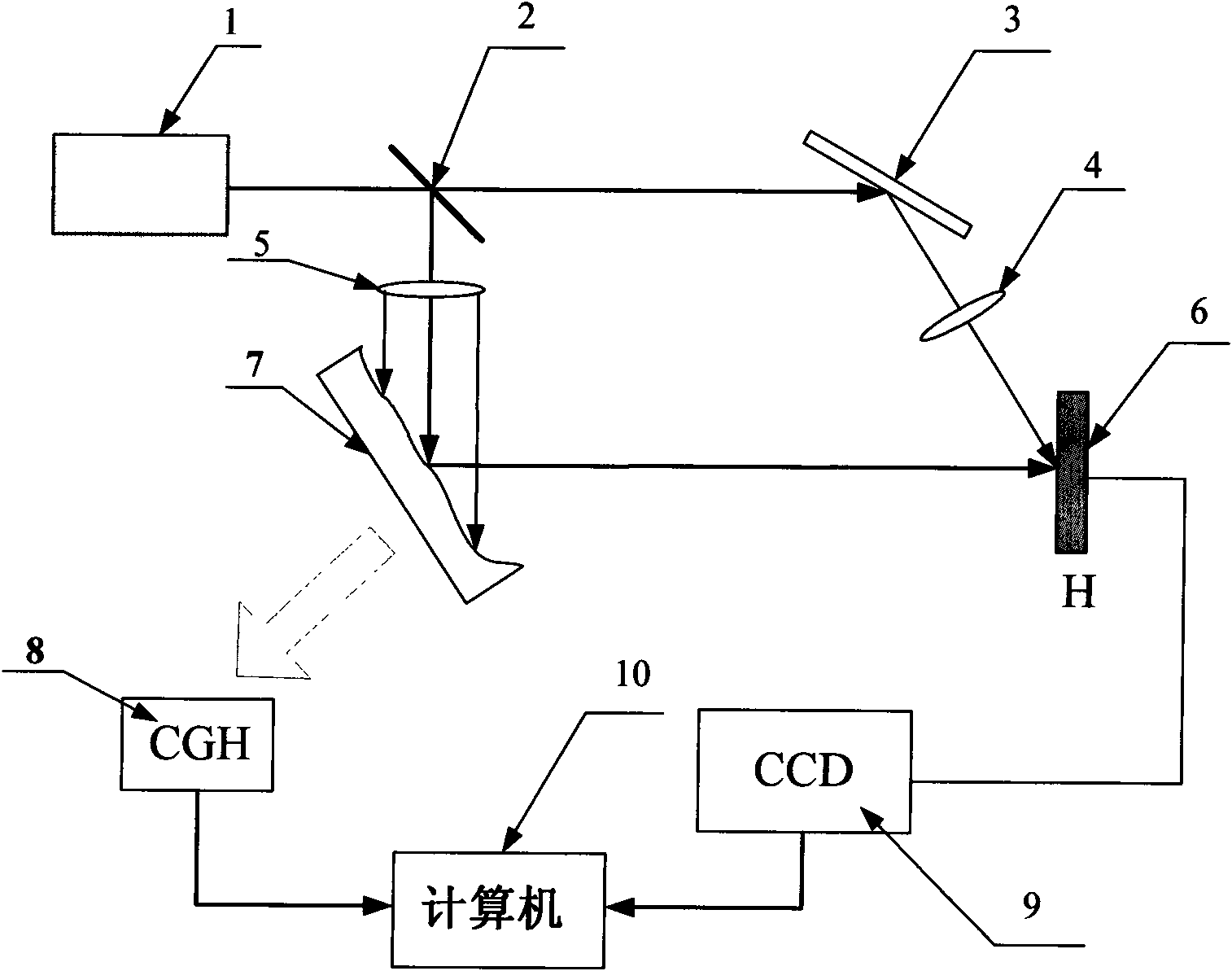

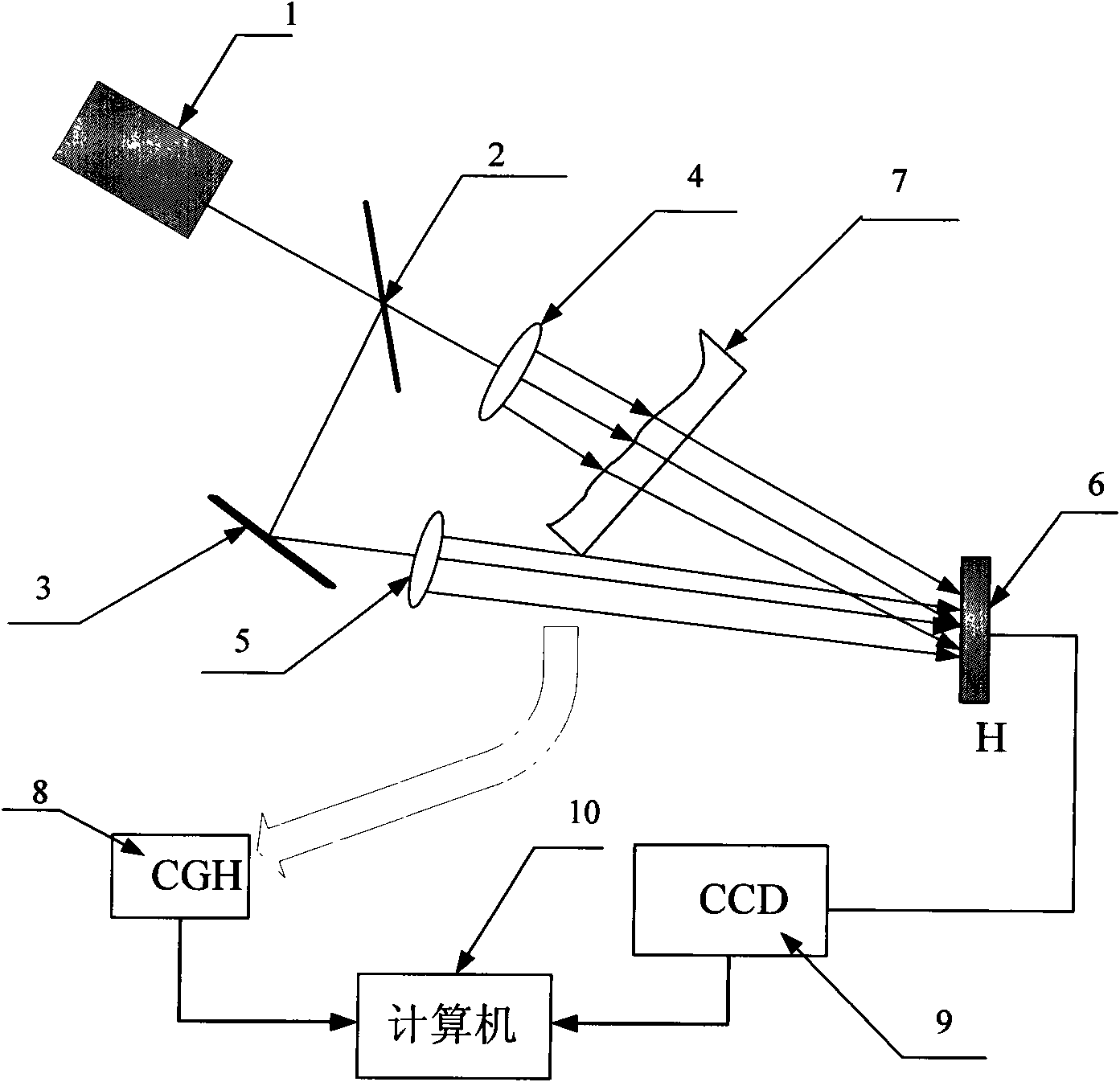

[0031] According to the mathematical model of the measured free-form surface, the present invention generates a corresponding computational holographic CGH, performs holographic detection on the actual free-form surface to be measured, and records the hologram on the medium. The recorded hologram is sampled to obtain a digital hologram, and the digital hologram and CGH are digitally reproduced in the computer respectively to obtain the wavefront information of the free-form surface to be measured and the CGH, and then the two wavefronts are coherently superimposed, Through the image processing of the interferogram, the three-dimensional shape information of the free-form surface can be obtained.

[0032] The present invention comprises the following steps:

[0033] The first step is to generate a computational holographic CGH with an ideal free-form surface wavefront according to the mathematical model of the ideal free-form surface, and store it in the computer; the hologram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com