Edge expansion type high coupling coefficient non-contact transformer

A high-coupling, transformer technology, applied in the direction of transformer/inductor core, inductor/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problems of low coupling coefficient and heavy core weight, etc. To achieve the effect of increasing the coupling coefficient and increasing the width of the window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The accompanying drawings disclose several specific implementation examples of the present invention without limitation, and the present invention will be further described as follows in conjunction with the accompanying drawings.

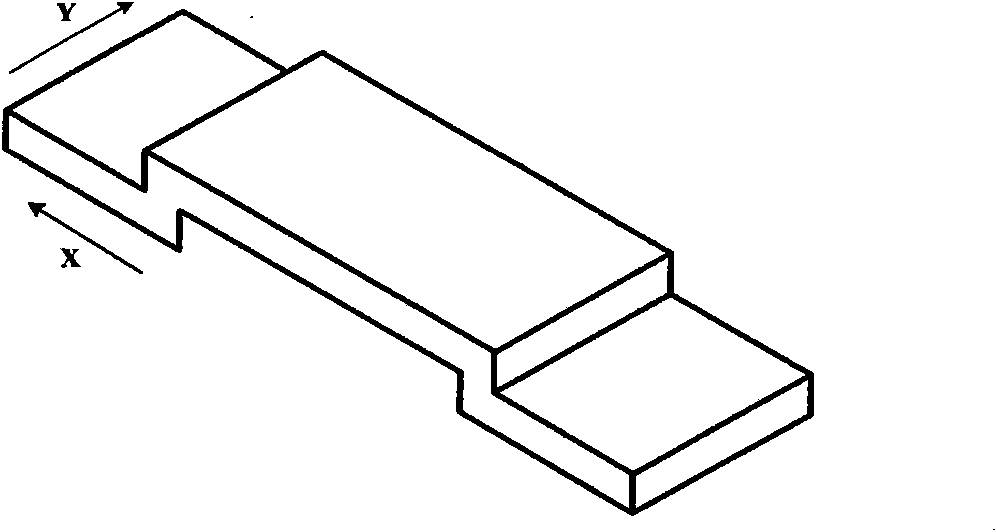

[0025] See attached figure 1 , the extended part of the magnetic core adopts a rectangular shape, and only expands in one direction along the X direction of the magnetic core window width.

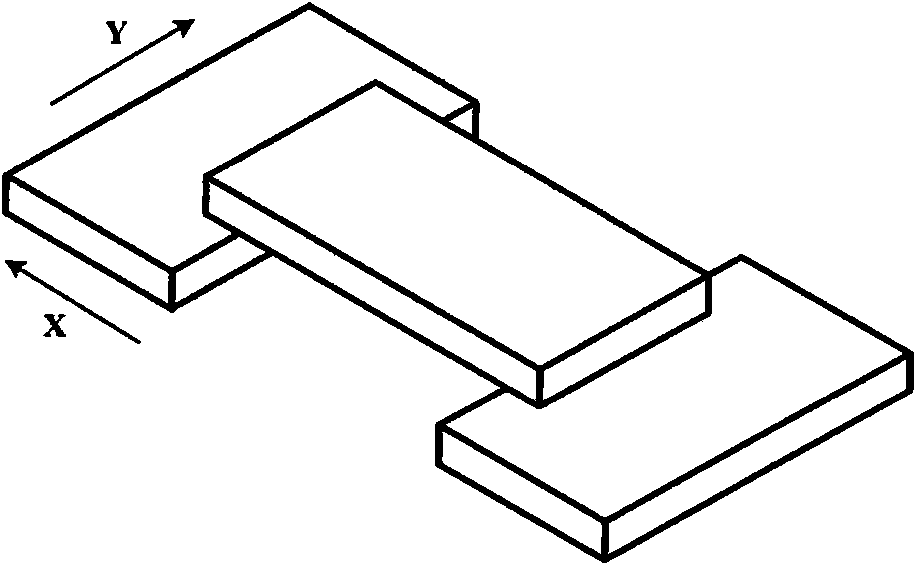

[0026] See attached figure 2 , the edge extension part of the magnetic core adopts a rectangular shape, and bidirectionally expands along the X direction of the magnetic core window width and the Y direction of the window depth.

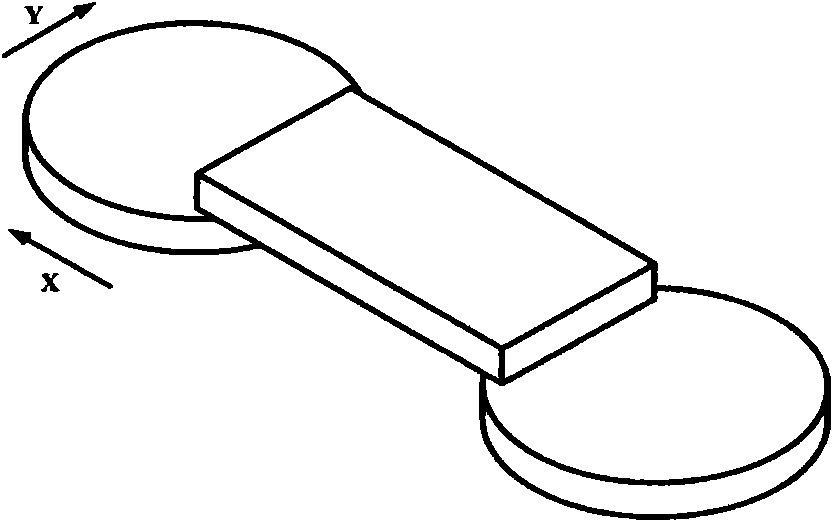

[0027] See attached image 3 , the edge extension of the magnetic core adopts a circular shape, and expands bidirectionally along the X direction of the magnetic core window width and the Y direction of the window depth.

[0028] See attached Figure 4 , the edge extension of the magnetic core adopts a hexagonal shape, and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com