Distribution method and distribution device of mobile phases of chromatographic columns

A distribution method and a technology of a distribution device, which are applied in the field of mobile phase distribution in a chromatographic column, can solve the problems of reduced distribution uniformity, uneven initial fluid distribution, and influence on separation effect, so as to achieve easy clogging, easy cleaning and repeated use, The effect of simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

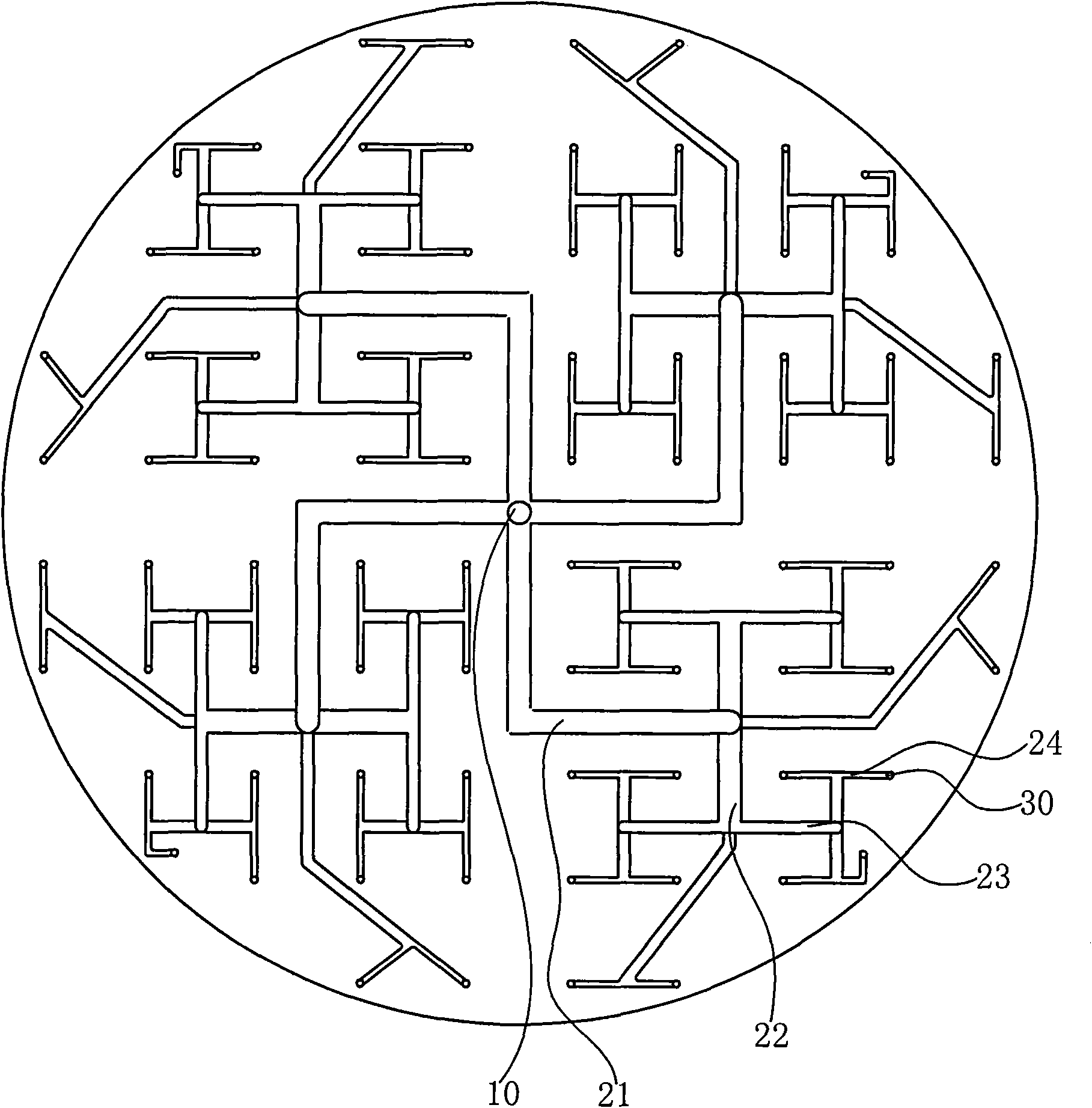

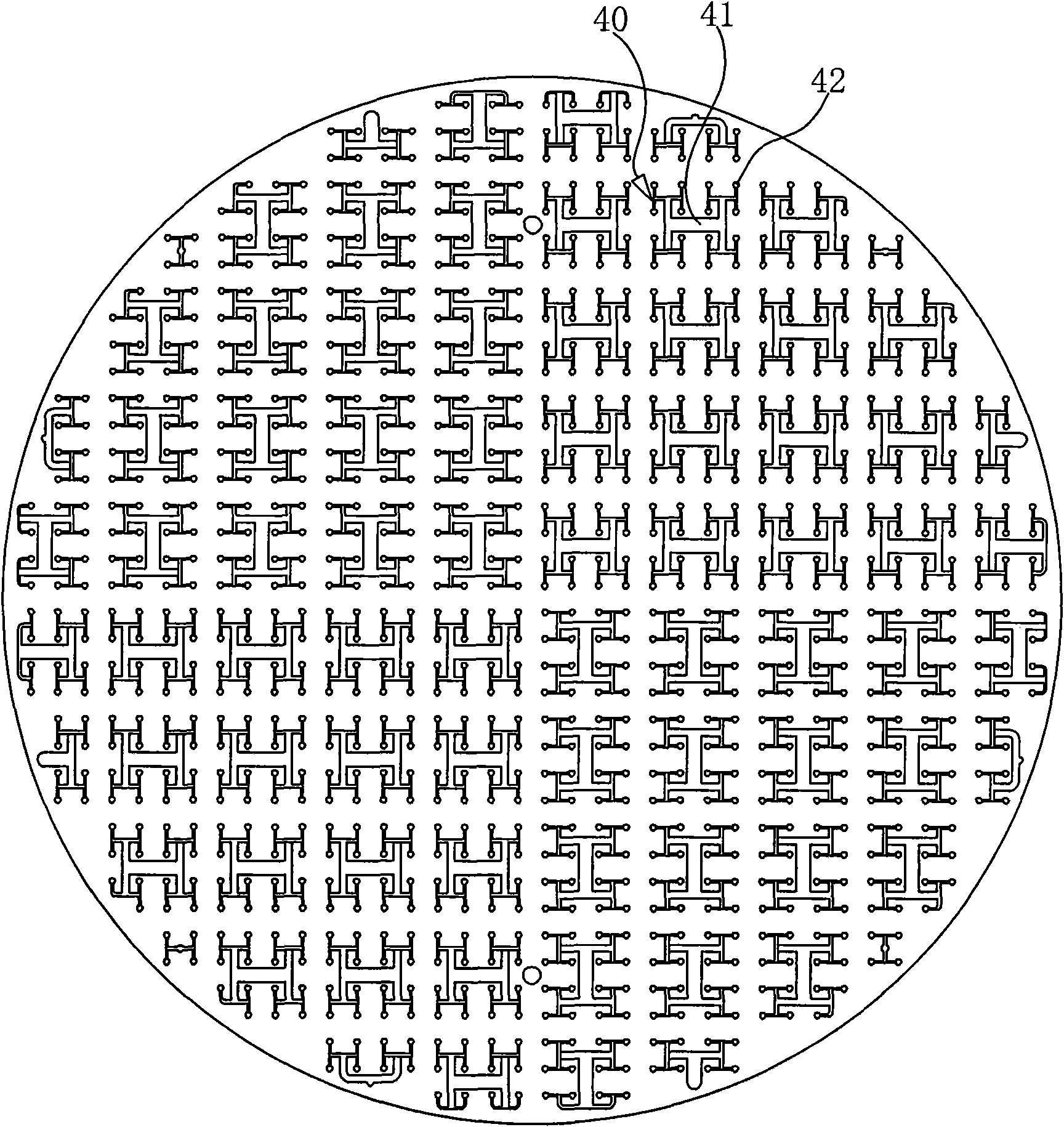

[0026] The mobile phase distribution method of the chromatographic column is used to distribute the mobile phase on the upper surface of the stationary phase in the preparation chromatographic column. It adopts a circular distributor that matches the cross-section of the preparation chromatographic column. The outer tree diverges to set the fluid phase distribution liquid path, and the end of each fluid phase distribution liquid path is provided with a distribution hole, and the length of the fluid phase distribution liquid path of the same specification from the center of the distributor to each distribution hole is equal; the fluid phase Distribute evenly from the center of the distributor along the distribution path of each fluid phase to each distribution hole, and then evenly distribute to the stationary phase of the chromatographic column. The liquid phase distribution liquid path includes a plurality of first distribution liquid paths that diverge from the center to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com