Coal digging machine

A technology of coal diggers and manipulators, applied in cutting machinery, ground mining, earth drilling and mining, etc., can solve the problems of non-open-pit coal mines, such as poor applicability, inability to meet production needs, and high labor intensity of workers, and achieve compact structure , long service life and high coal mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

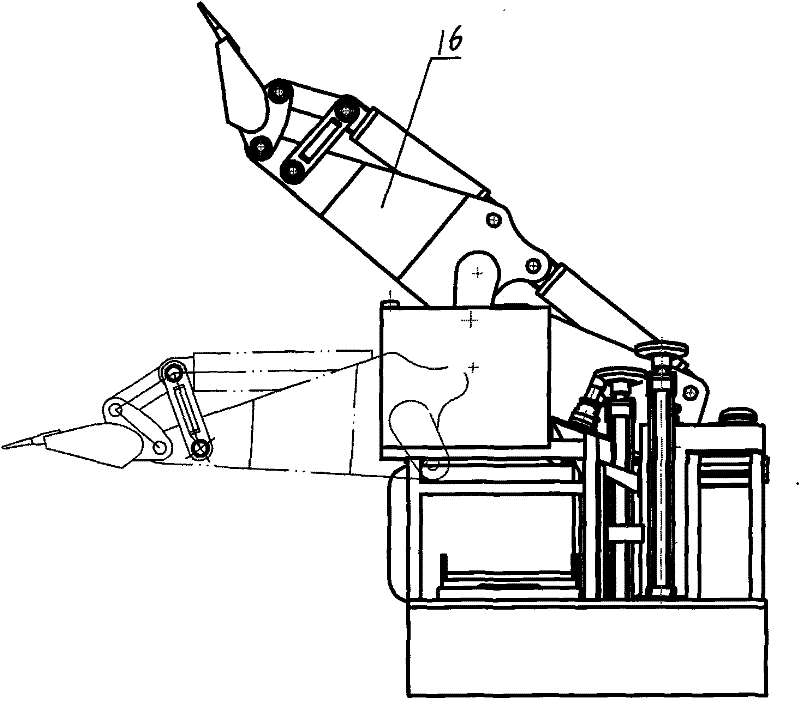

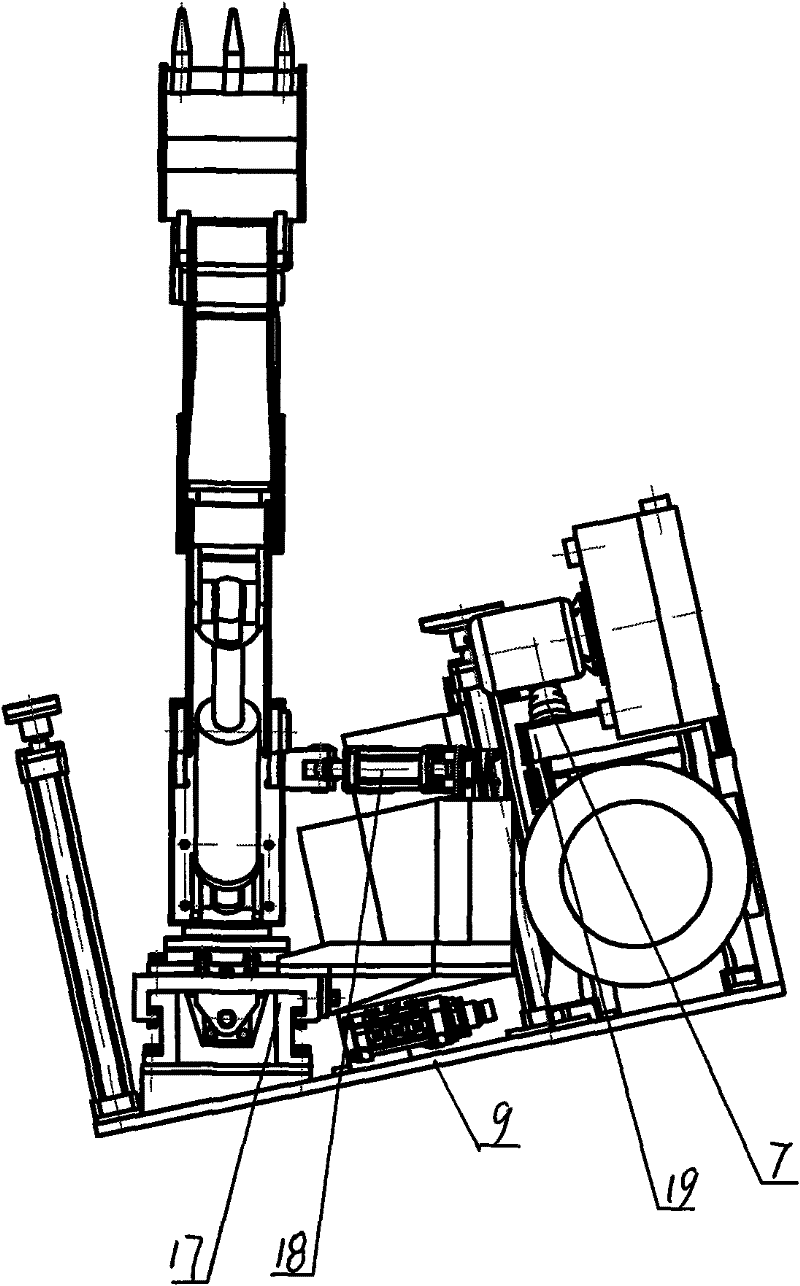

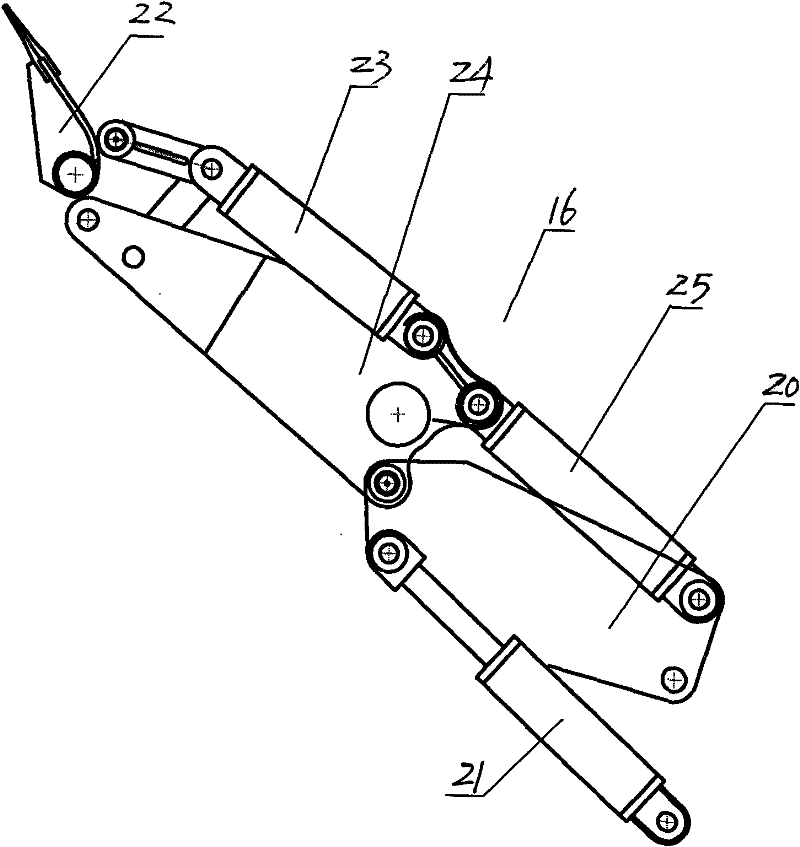

[0015] exist figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Among them, the coal excavator includes a hydraulic system 7, an electrical system 19, a manipulator 16, a moving device 17, a slewing device 18 and a base 9, and the hydraulic system is mainly composed of a hydraulic oil tank assembly, a main motor oil pump Road reversing valve, manual pilot valve, manual reversing valve, hydraulic oil air cooling device and pressure measuring device; the manipulator 16 includes a bucket 22, bucket cylinder 23, arm 24, arm cylinder 25, arm 20 and boom oil cylinder 21, controlling the extension and contraction of the boom oil cylinder can make the boom move up and down; The arm moves back and forth, and the bucket oil cylinder is controlled to expand and contract to make the bucket excavate; the moving device 17 includes a moving oil cylinder 12, a sliding table 11, a sliding seat 14, an inlay 13, a bottom plate 10 and a replaceable chassis 15. The moving device can ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com