Method and mechanism for controlling deflection angle of blade of vertical axis wind turbine

A wind turbine blade and angle control technology, which is applied to the control of wind turbines, wind turbines at right angles to the wind direction, wind turbines, etc., can solve the problems affecting the wind energy utilization coefficient of wind turbines, the difficulty of wind turbine maintenance, slider lubrication and Sealing troubles and other problems, to achieve the effect of increasing the utilization coefficient of wind energy, easy processing and installation, easy lubrication and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

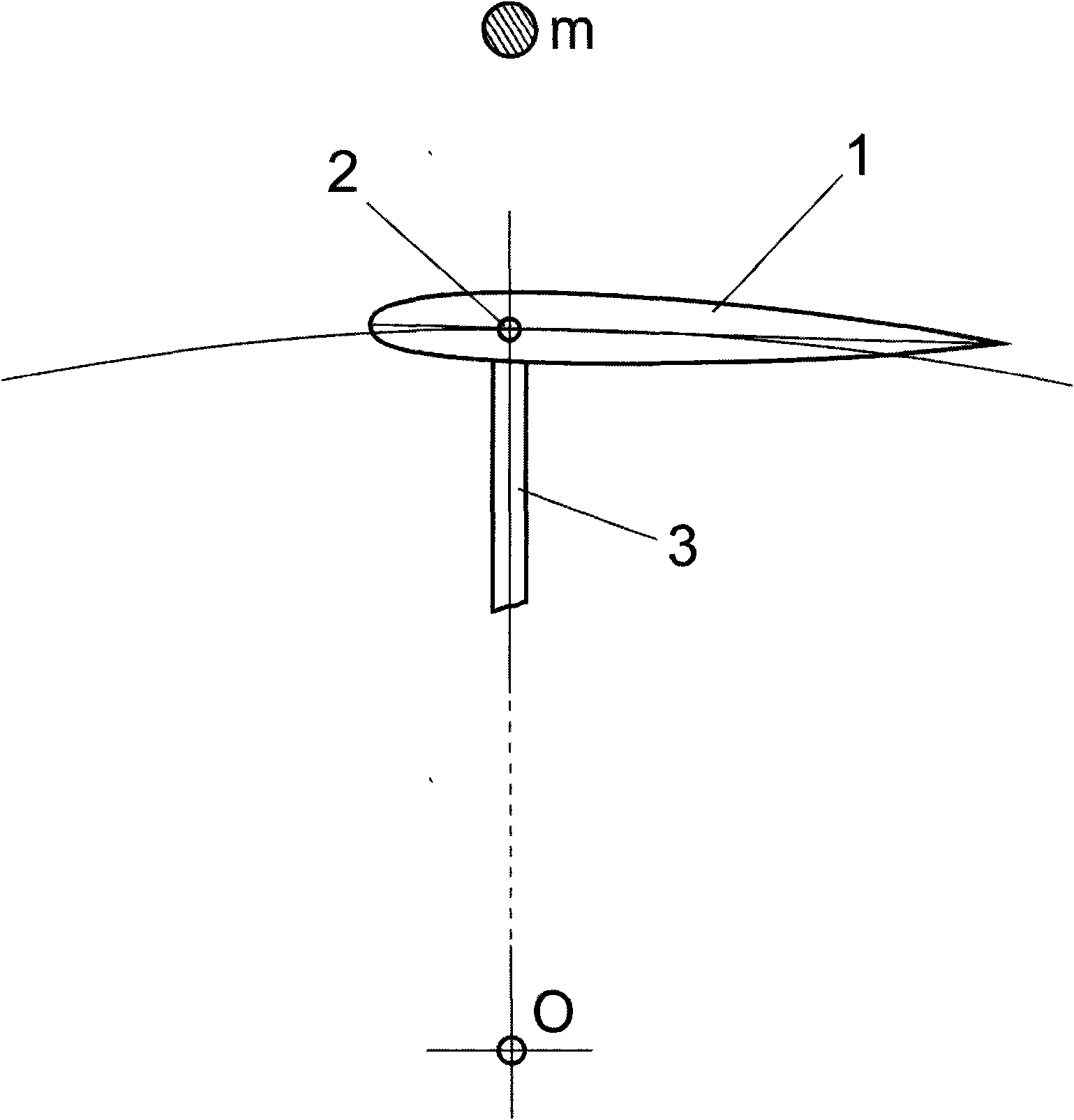

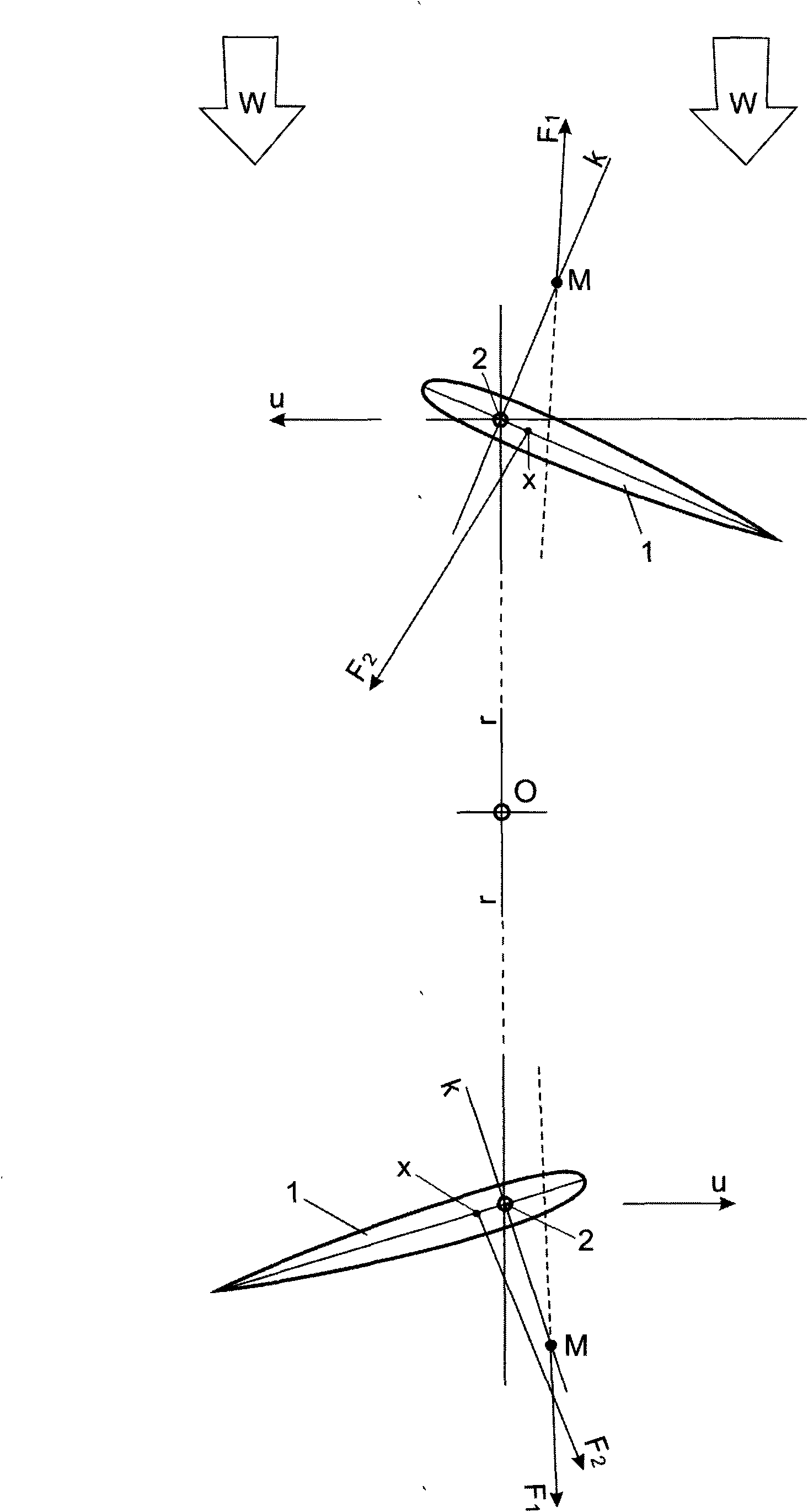

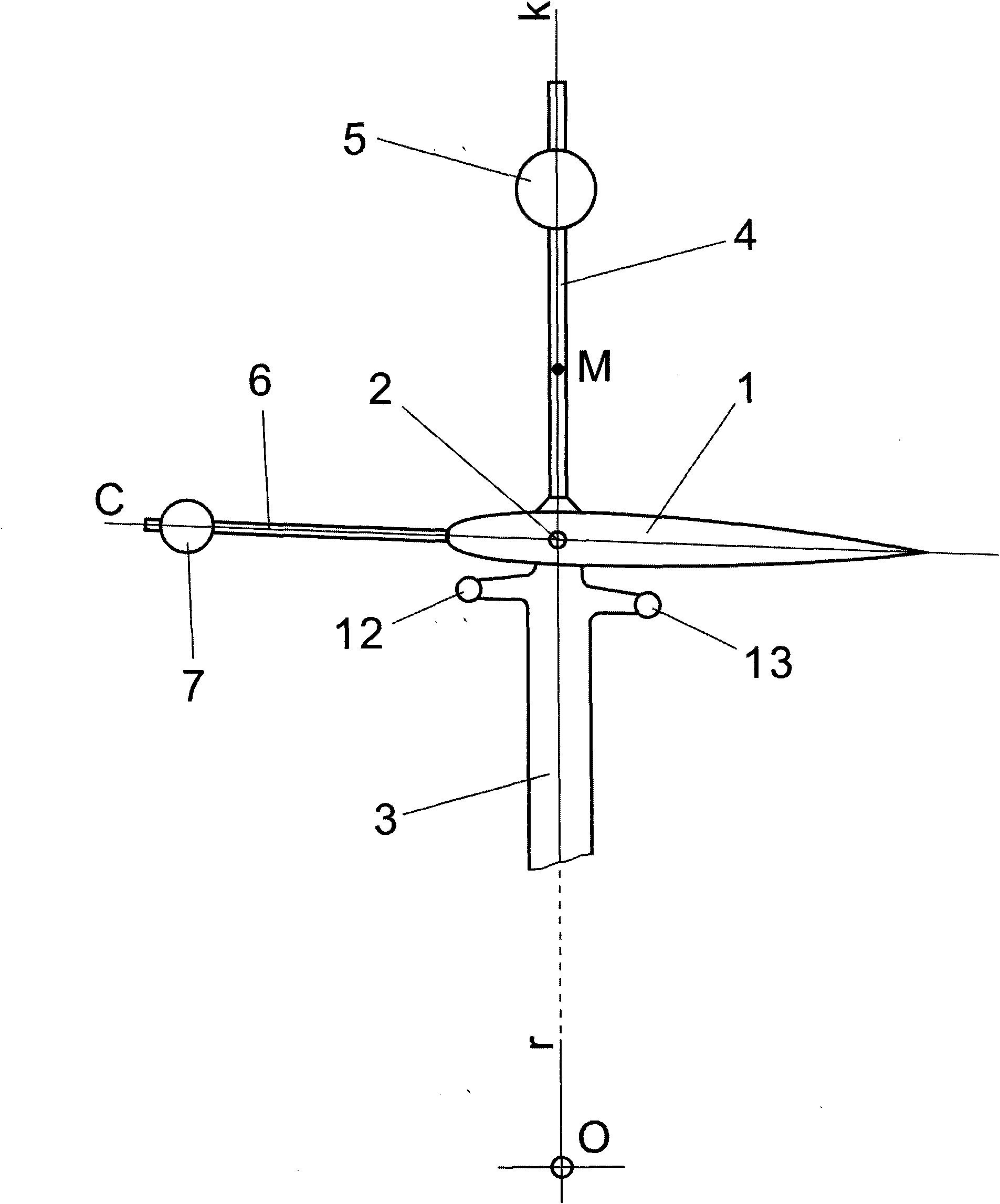

[0039] The blade 1 of the pendulum control mechanism for controlling the yaw angle of the vertical axis wind turbine blade of the present invention adopts a symmetrical airfoil. The blade 1 has a blade shaft 2 whose axis is parallel to the length of the blade and is the same as the axis of the central shaft O of the wind turbine. On a plane r. The position of the blade shaft 2 is as close as possible to the middle arc line of the blade (the middle arc line of the symmetrical airfoil coincides with the blade chord line), and the blade shaft 2 is in front of the pressure center of the blade (the symmetric airfoil can be selected at 1 / 4 of the leading edge of the blade Chord length forward position), the blade 1 is installed on the wind turbine bracket 3 through the blade shaft 2, and the blade 1 can rotate around the blade shaft 2, see figure 1 , image 3 .

[0040] The vertical axis wind turbine blade yaw angle control mechanism of the present invention adopts the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com