Radiation type building brick combination door neck brick and building method thereof

A masonry and door lock technology, which is applied to furnaces, lining repairs, lighting and heating equipment, etc., can solve problems such as large gaps in brick bodies, loose brick rings, and affecting service life, so as to reduce costs, reduce labor intensity, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

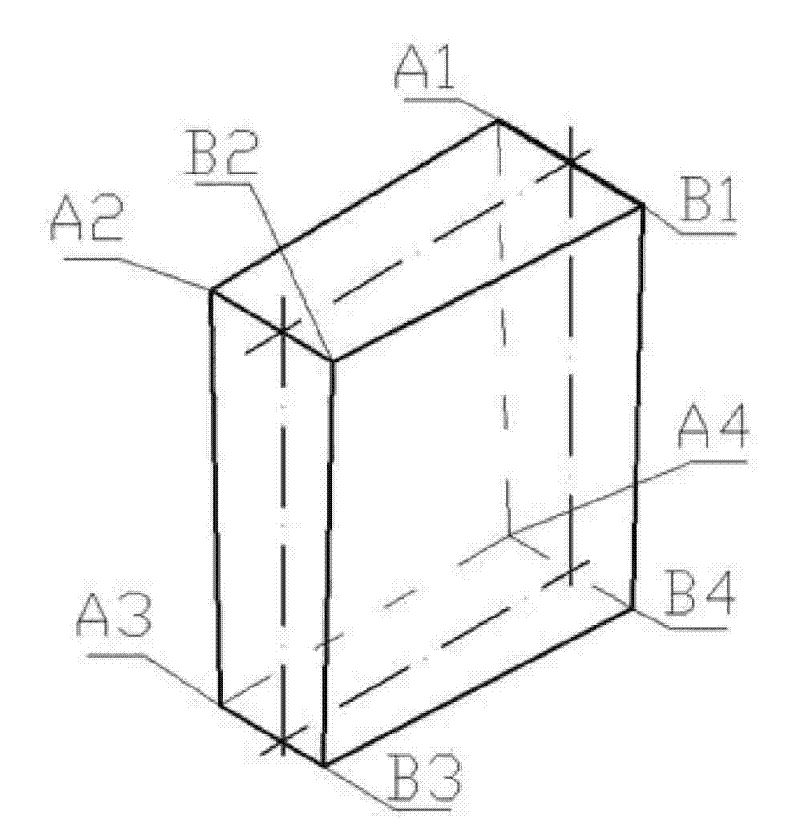

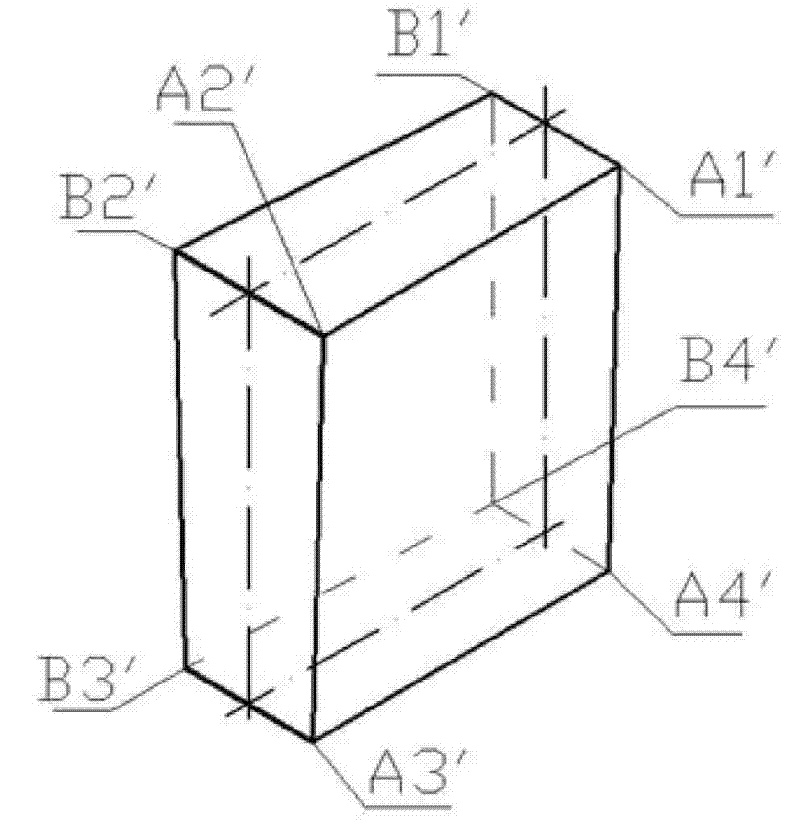

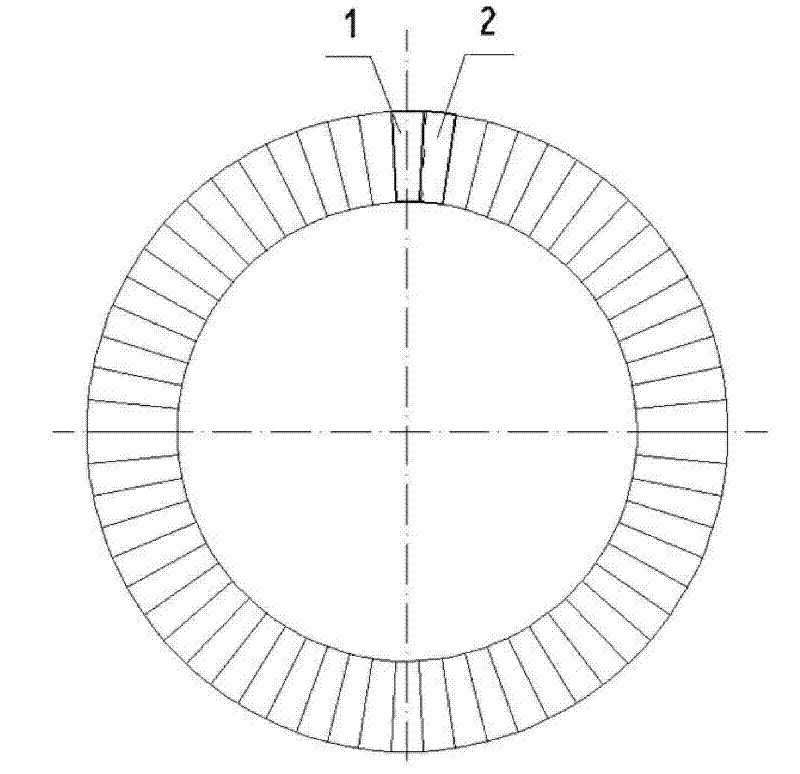

[0057] The shape characteristics of the radial brick ring-closed door lock brick proposed by the present invention are as follows:

[0058] Each type of radiant-shaped brick ring-joint door lock brick is composed of a first brick and a second brick that are used in conjunction with each other. A certain angle, that is, the B surface and the A surface are inclined to form a certain angle, and the C surface and the D surface are inclined to form a certain angle, and the B surface and the C surface become an inclined surface, and the inclined surface and the radiation line of the masonry ring where the brick is placed during masonry The angles between them are all smaller than the self-locking friction angle of the brick itself, and the slope is the structural surface where the first brick and the second brick are attached to each other. The opposite surfaces of the structural surfaces where the first brick and the second brick are attached to each other, that is, the A surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com