Reversing-free DC electric generator and power generation method thereof

A technology of direct current generator and direct current, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., and can solve the problems of fast brush wear, low efficiency, and capacity limitation of a single machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Since the power generation method is used in the design and manufacture of generators, the power generation method can only be implemented in the form of generators.

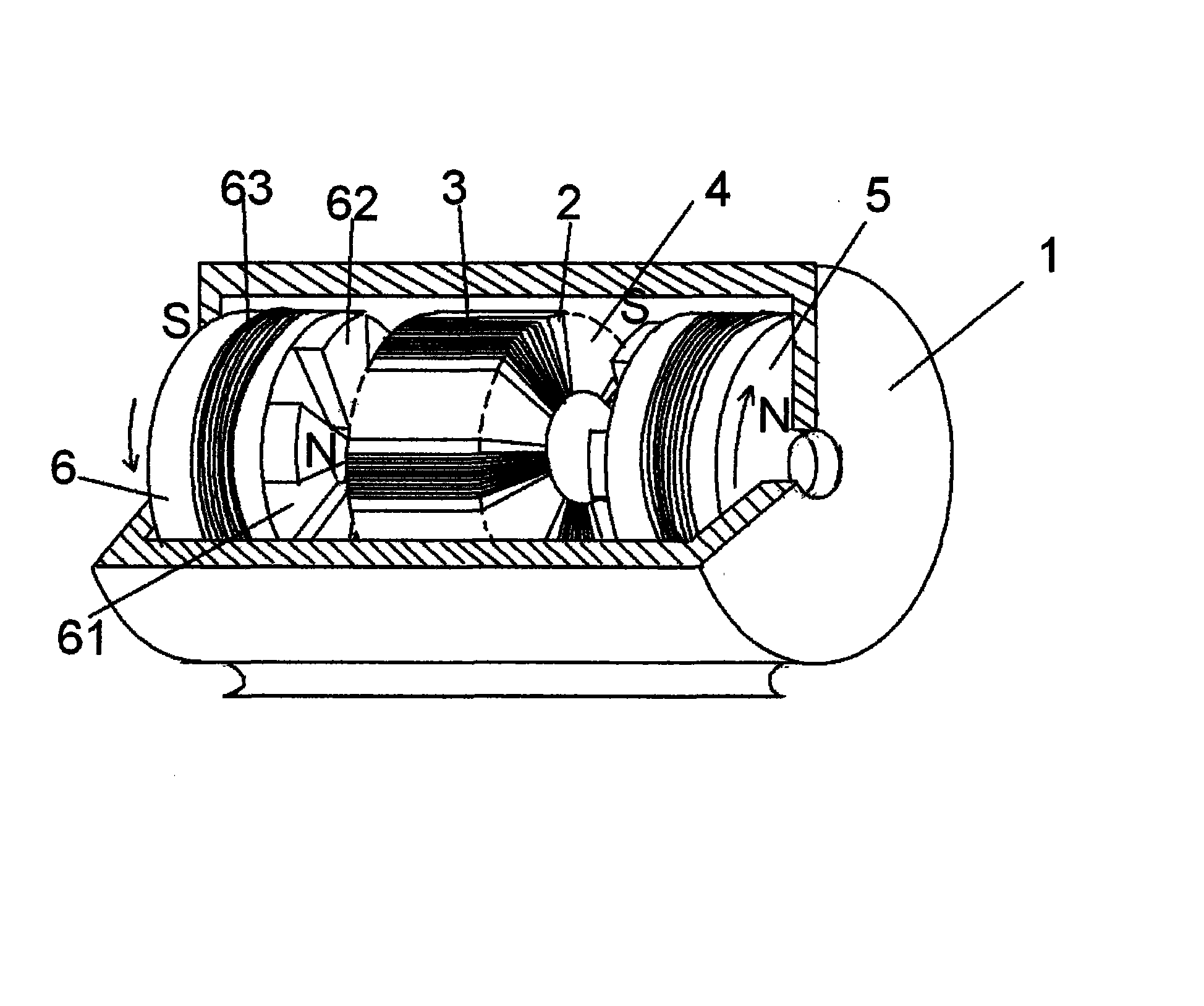

[0014] The attached drawing is a three-dimensional schematic diagram of the generator, which is mainly composed of three parts: the stator armature, the rotor magnet, and the frame yoke.

[0015] Among them, the stator armature is composed of coil 3 and iron core 2, and the armature is composed of several coils with independent iron cores. Both form their own independent magnetic fields, and the space 4 between the coils is filled with a dielectric, so that the armature can be integrated as a whole, and the thermal effect can be removed by the medium to reduce the internal heat of the motor. Each coil is wound in the same direction, and fixed on the base after forming a circle. Each core coil is a fan-shaped body, and the core is made of soft magnetic material with high magnetic permeability, usually sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com