Optical sheets

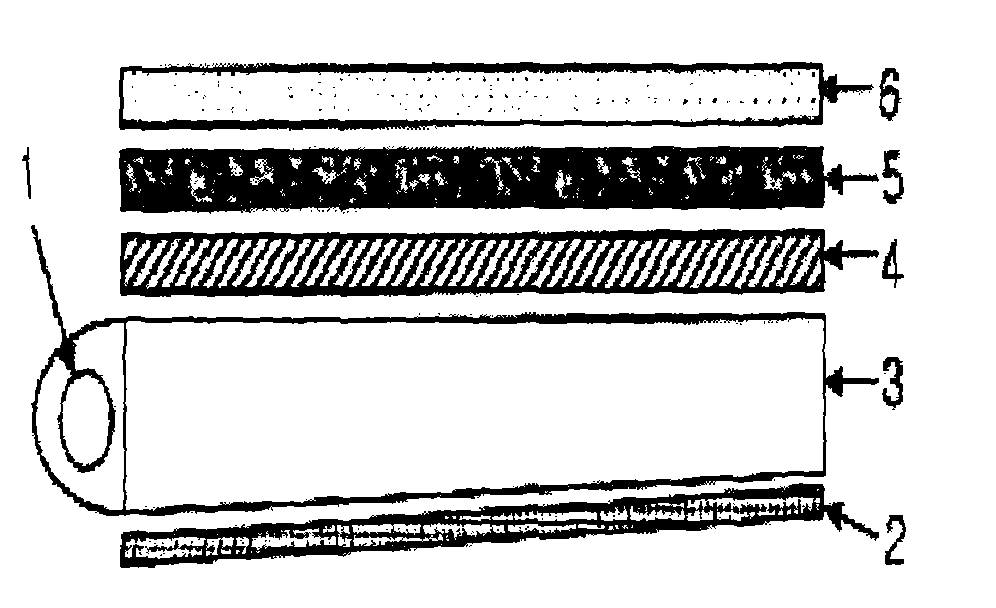

An optical sheet and light diffusion technology, applied in the field of optical sheets, can solve problems such as light loss, and achieve the effects of reducing light loss, preventing brightness, and reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

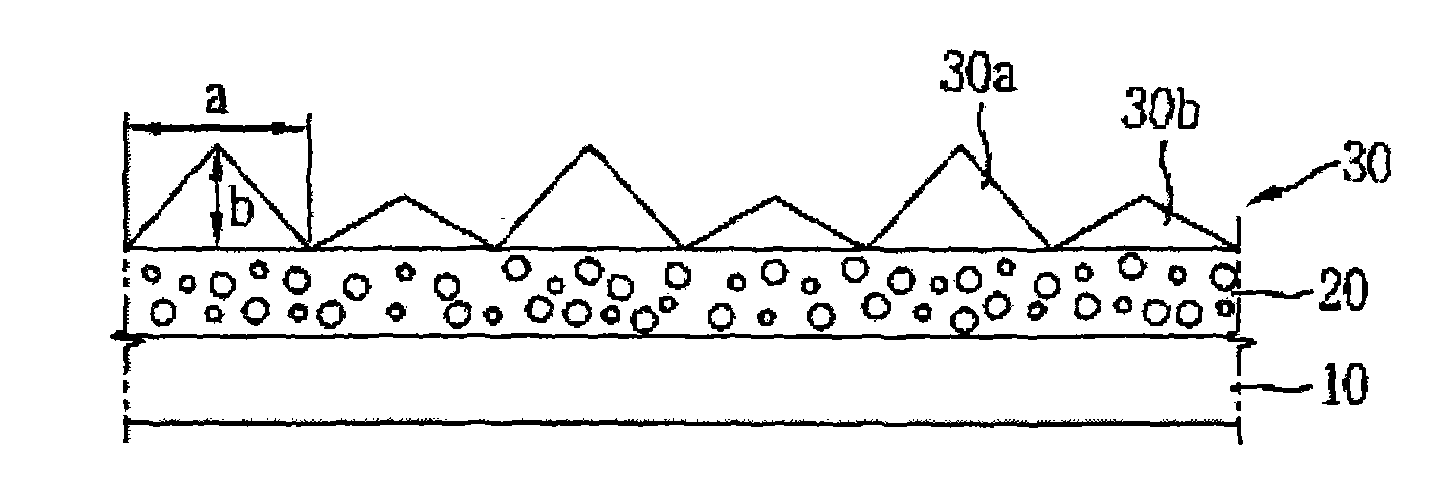

[0074] A binder resin having a refractive index of 1.50 was prepared by diluting 100 parts by weight of acrylic resin (52-666 available from Aekyung Chemical Company) with 70 parts by weight of methyl ethyl ketone and 50 parts by weight of toluene , then based on the weight of the binder resin, the average particle size is 20 μm and spherical polymethyl methacrylate particles (MH20F sold by Kolon Company) with a refractive index of 1.50, mixed in an amount of 110 parts by weight, Then use a milling machine to perform a monodisperse treatment in the form of a single layer, and then use a gravure coater to coat it on an ultra-transparent polyethylene terephthalate with a thickness of 188 μm as a transparent substrate layer. On one surface of a film (FHSS available from Kolon Corporation), it was then cured at 120C for 60 seconds, thereby forming a light-diffusing layer (refractive index 1.50) with a dry thickness of 25 μm.

[0075] In addition, on one surface of the cured light-...

example 2

[0077] Except that a prism layer having a nonlinear triangular prism and a refractive index of 1.53 was formed on one surface of the light diffusion layer, an optical composite film was manufactured in the same manner as Example 1.

example 3

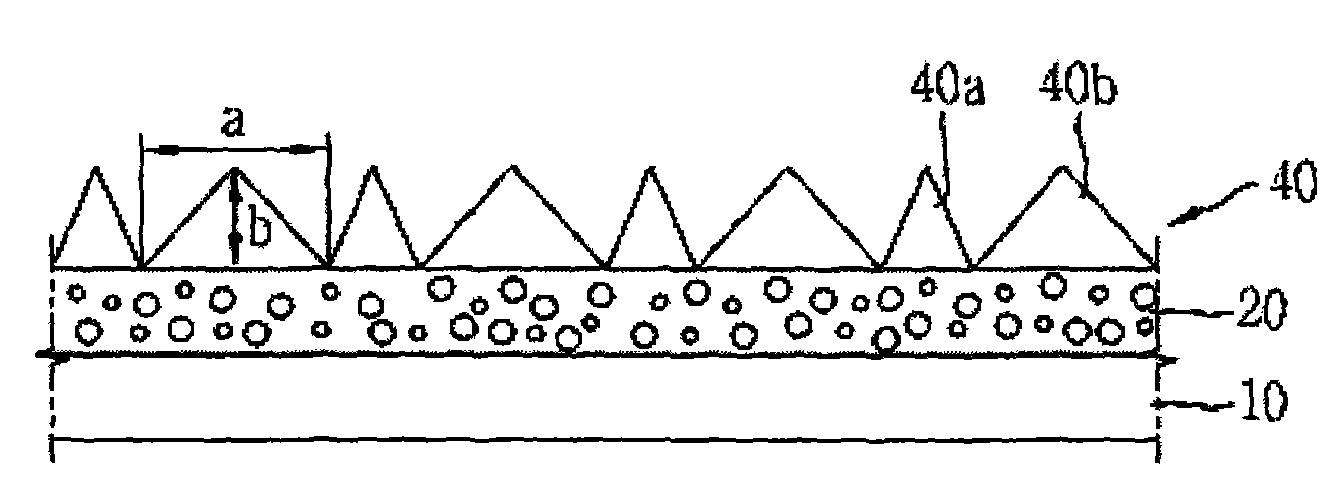

[0079] An optical composite film was manufactured in the same manner as in Example 1 except that the light-diffusing particles were dispersed in a multi-layered form during the formation of the light-diffusing layer. As for this light diffusion layer, its thickness is 30 to 35 μm, and its refractive index is 1.50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com