Chip fuse and process for producing the same

A fuse and chip technology, which is applied in the manufacture of fuses, electrical components, circuits, etc., can solve the problems of not disclosing the heat release device or method of fuse components, and not conducting specific research, etc., and achieves good thickness uniformity and good precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, an embodiment of the present invention will be described with reference to the drawings, but the present invention is not limited thereto.

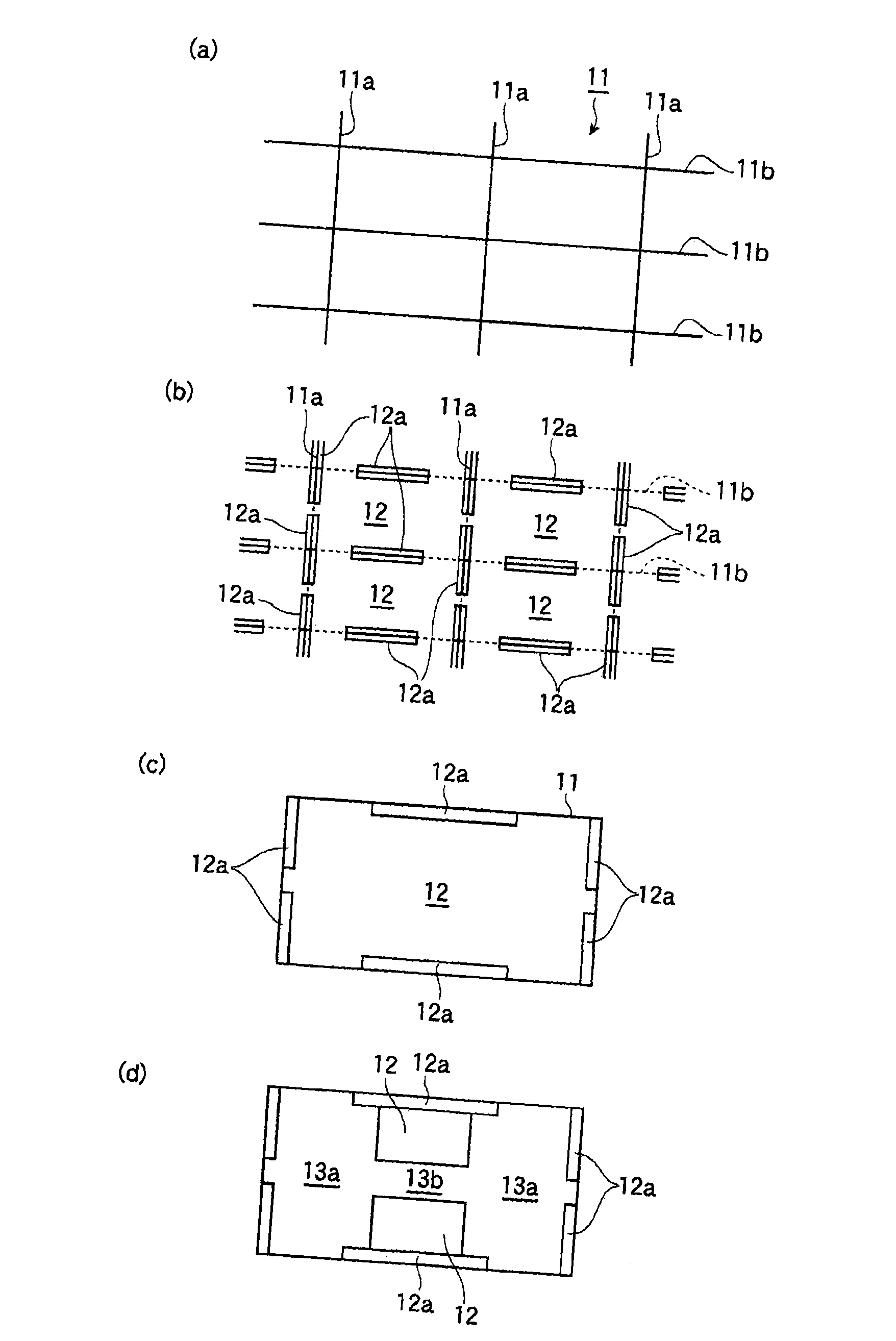

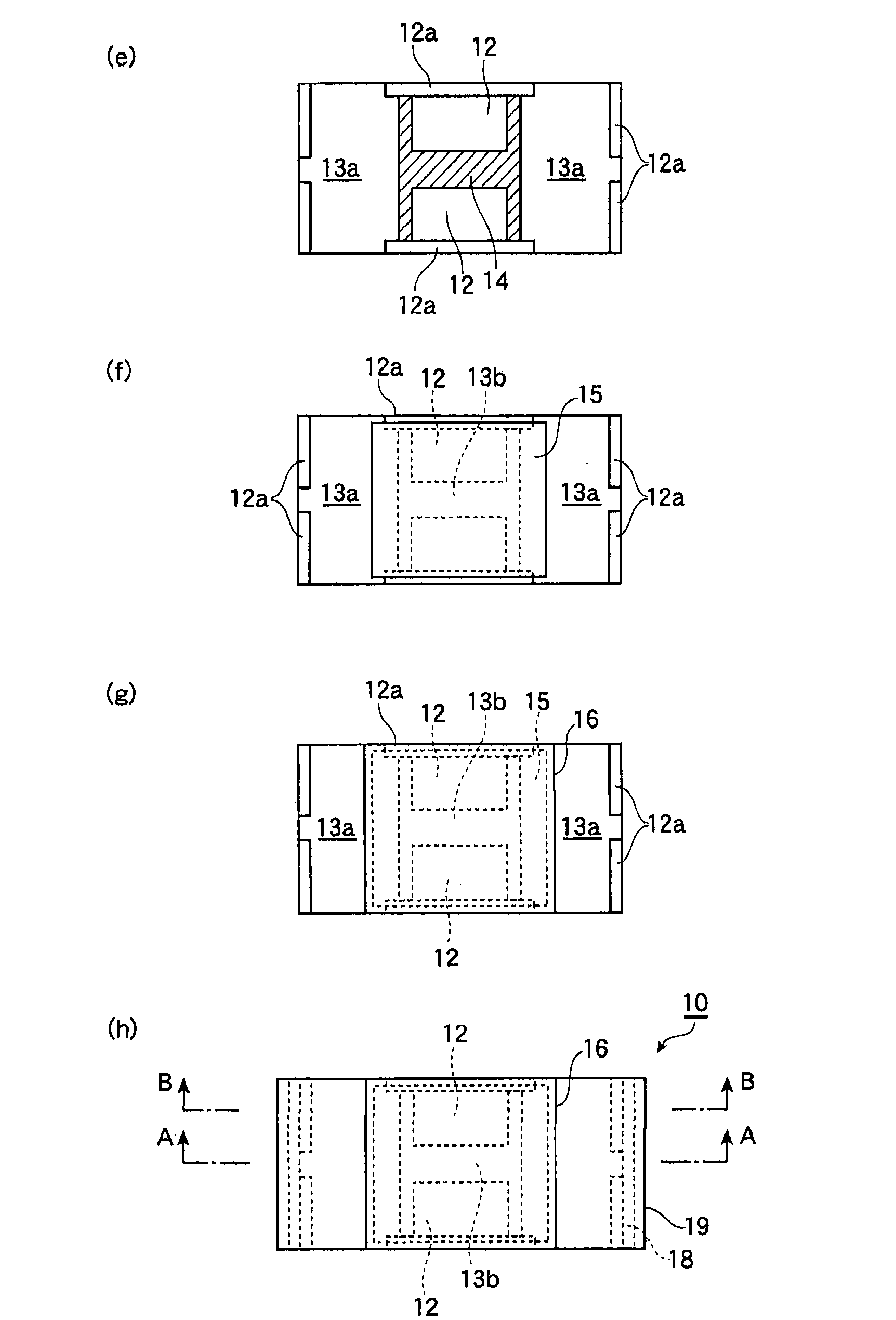

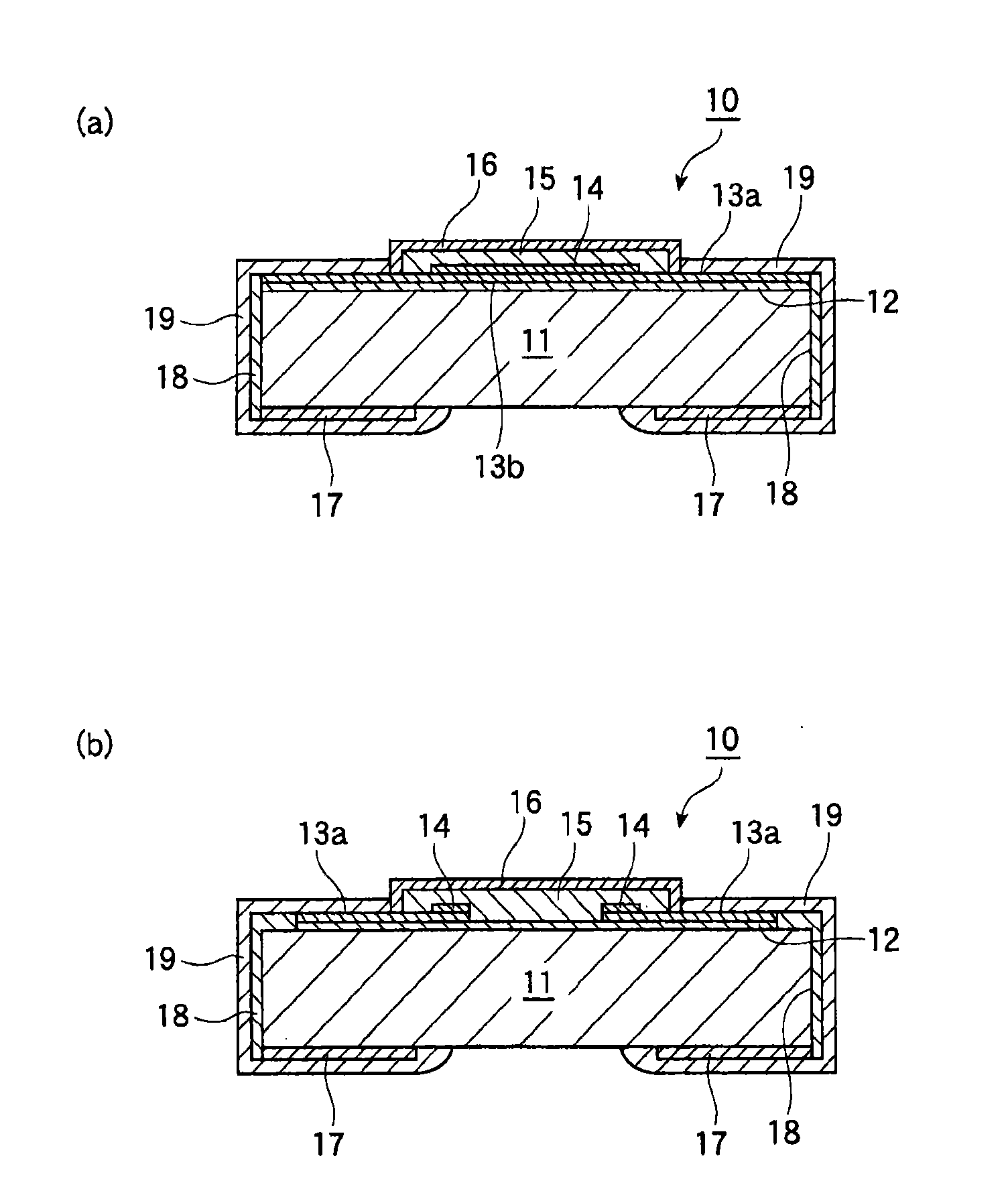

[0034] figure 1 (a)~(d) and figure 2 (e) to (h) are plan views showing the steps of manufacturing the chip fuse 10 of the present invention, image 3 (a) is along figure 2 The sectional view of the chip fuse 10 of the A-A line of (h), image 3 (b) is along figure 2 (h) Cross-sectional view of the chip fuse 10 of the B-B line.

[0035] In the chip fuse 10, a first heat storage layer 12 made of a film material with low thermal conductivity is formed on an insulating substrate 11, and a fuse film 13 is arranged on the first heat storage layer 12. The fuse film 13 There are surface electrode portions 13a arranged at both ends and a fuse element portion 13b formed with a relatively narrow width so as to connect the surface electrode portions 13a at both ends, and a portion of the surface electrode portion 13a and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com