Big square billet heavy rail steel functional protective material

A technology for protecting materials and heavy rail steel, which is applied in the field of metallurgical auxiliary materials and can solve problems such as internal cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

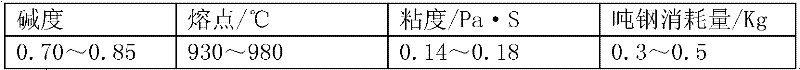

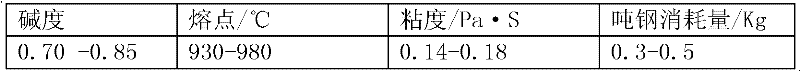

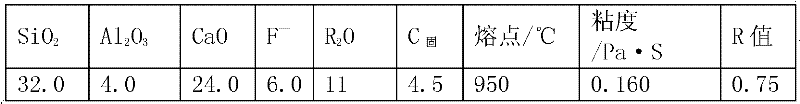

[0015] A protective material for continuous casting of heavy rail steel, in which SiO 2 The mass percentage content is 32.0%, Al 2 o 3 The mass percentage of CaO is 4.0%, the mass percentage of CaO is 24%, F - The mass percentage content is 6%, R 2 The mass percentage content of O is 11%, and the mass percentage content of C is 4.5%.

[0016] The continuous casting protective material has a melting point of 950° C., a viscosity of 0.160 Pa·S, and an R value of 0.75.

[0017] Since Angang heavy rail steel bloom continuous casting adopts multi-point straightening full-arc continuous casting machine, the crystallizer equipment has liquid level control system and electromagnetic stirring system. After the molten steel is vacuum refined, the content of inclusions in the molten steel is low, so the continuous casting protective material must be melted evenly, so as to avoid uneven melting of the continuous casting protective material and slag entrainment under the unreasonable m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com