Carbon, graphite/steel composite lifting tooling used for high-temperature furnaces

A high-temperature furnace, carbon composite material technology, applied in transportation and packaging, cranes, walking bridge cranes, etc., can solve the problems of poor performance, high manufacturing cost, inconvenient operation, etc., and achieve low manufacturing cost and easy operation. , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

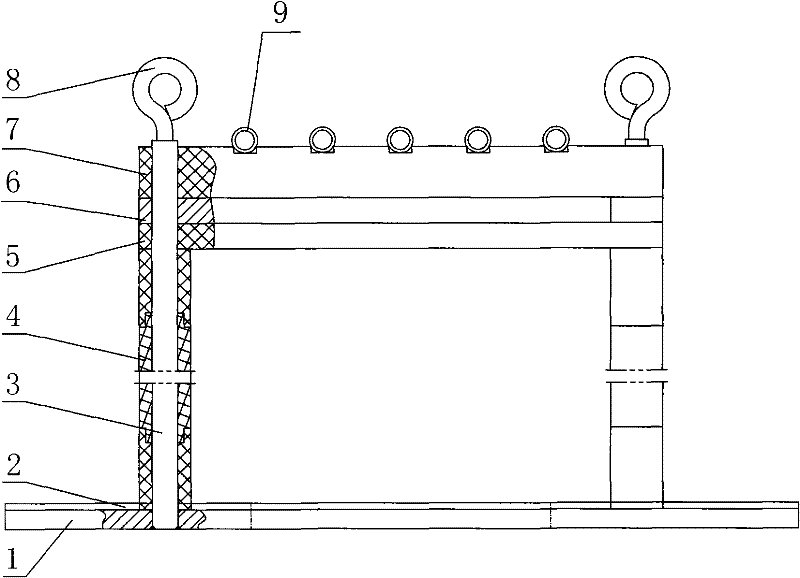

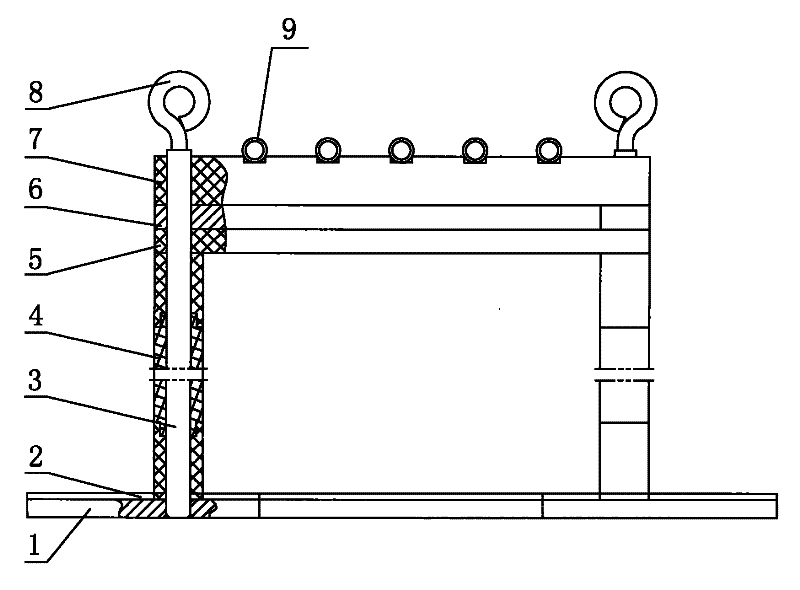

[0023] like figure 1 As shown, the present invention includes a base composed of a heat-resistant steel base plate 1 and a low-density carbon / carbon composite material plate 2 fixed on the upper surface of the heat-resistant steel base plate 1, supported and fixed on the base plate by a plurality of heat-resistant steel columns 3 The heat-resistant steel top beam frame 6 directly above the base, the graphite plate frame 5 placed under the heat-resistant steel top beam frame 6, placed on the heat-resistant steel top beam frame 6 and used for hanging in the high-temperature furnace to be processed to generate heat The graphite beam 7 of the body product and a plurality of heat-resistant steel hooks 8 above the graphite beam 7. The heat-resistant steel column 3 is fixed on the base, and the heat-resistant steel column 3 is covered with a graphite tube 4 , and the graphite beam 7 is correspondingly provided with a plurality of graphite hanging structures 9 . In this embodiment, t...

Embodiment 2

[0029] In this embodiment, the heat-resistant steel bottom plate 1 has a thickness of 30mm and a diameter of 1500mm. The density of carbon / carbon composite plate 2 is 0.8g / cm 3 , a diameter of 1500mm and a thickness of 25mm. The quantity of described heat-resistant steel column 3 is 4 and is fixed on the heat-resistant steel base plate 1 by welding, and the diameter of heat-resistant steel column 3 is 35mm, and height is 2500mm; The graphite tube 4 is made of electrode graphite and its outer diameter is 100mm, and the multi-section graphite tubes 4 are connected by self-locking. The thickness of the graphite plate frame 5 used is 60mm, the thickness of the graphite beam 7 is 100mm and its length is 1500mm. In this embodiment, the structures, functions, connections and working principles of other components are the same as those in Embodiment 1.

Embodiment 3

[0031] In this embodiment, the heat-resistant steel bottom plate 1 has a thickness of 50mm and a diameter of 2500mm. The density of the carbon / carbon composite plate 2 is 1.2g / cm 3, a diameter of 2500mm and a thickness of 40mm. The quantity of described heat-resistant steel column 3 is 4 and is all fixed on the heat-resistant steel base plate 1 by welding, and the diameter of heat-resistant steel column 3 is 50mm, and height is 4000mm; The graphite tube 4 is made of electrode graphite and its outer diameter is 200mm, and the multi-section graphite tubes 4 are connected by self-locking. The thickness of the graphite plate frame 5 used is 100mm, the thickness of the graphite beam 7 is 150mm and its length is 2300mm. In this embodiment, the structures, functions, connections and working principles of other components are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com