Method for recovering tetrahydrofuran from Grignard reaction waste residue of magnesium chloride

A technology of tetrahydrofuran and Grignard reaction, applied in the direction of organic chemistry, can solve the problems of difficult separation of magnesium and tetrahydrofuran, inability to recycle tetrahydrofuran, large loss of tetrahydrofuran, etc., and achieve the effect of high price, large amount of consumption, and reduction of product raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Step 1, dissolving and distilling, tetrahydrofuran is freed from magnesium chloride waste residue:

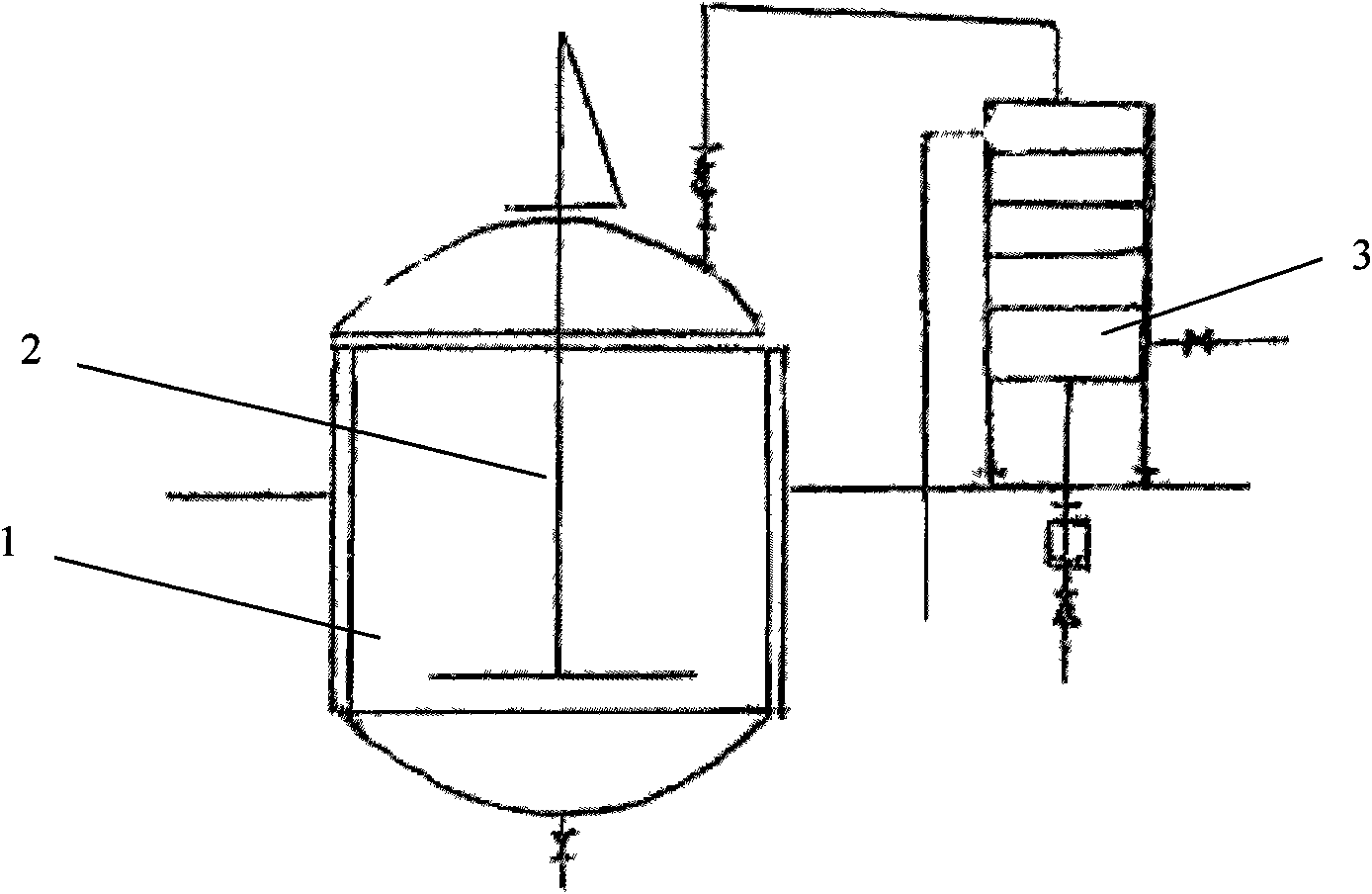

[0036] Such as figure 1 Shown is a schematic diagram of the structure of a dissolving still, which includes a glass-lined reactor 1 with a volume of 3000L to 5000L. An anchor stirrer 2 is set inside the reactor 1, and a condenser 3 is provided in the still. device 3 is 10m 2 Enamel chip condenser, the distilled product is received by receiver.

[0037] Add 1500kg of Grignard reaction waste residue magnesium chloride and 3000kg of water into the reaction kettle 1 of the above-mentioned dissolving distillation kettle, start stirring after sealing, turn on the cooling water of the glass-lined sheet condenser 3, stir for about half an hour, all the solids are dissolved, and heat through the jacket steam , the internal temperature is about 70°C, until the tetrahydrofuran vaporizes, escapes from the solution, and enters the condenser 3 in the form of steam, and after being c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com