Processing method to obtain asymmetric waveguide structure through processing on optical fiber

An asymmetrical waveguide and processing method technology, applied to metal processing equipment, control of workpiece feed movement, machine tools suitable for grinding workpiece planes, etc., to achieve good repeatability, low cost, and easy-to-master processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

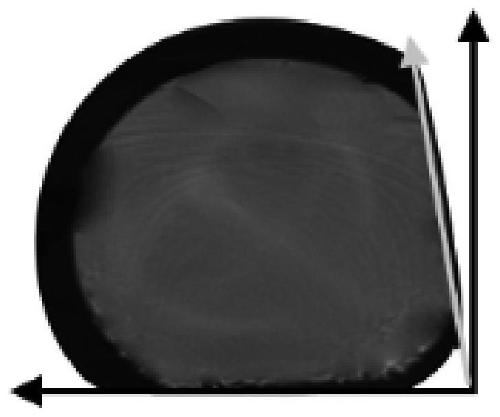

Image

Examples

Embodiment Construction

[0021] The present invention is further declared below in conjunction with embodiment, but should not limit protection scope of the present invention with this.

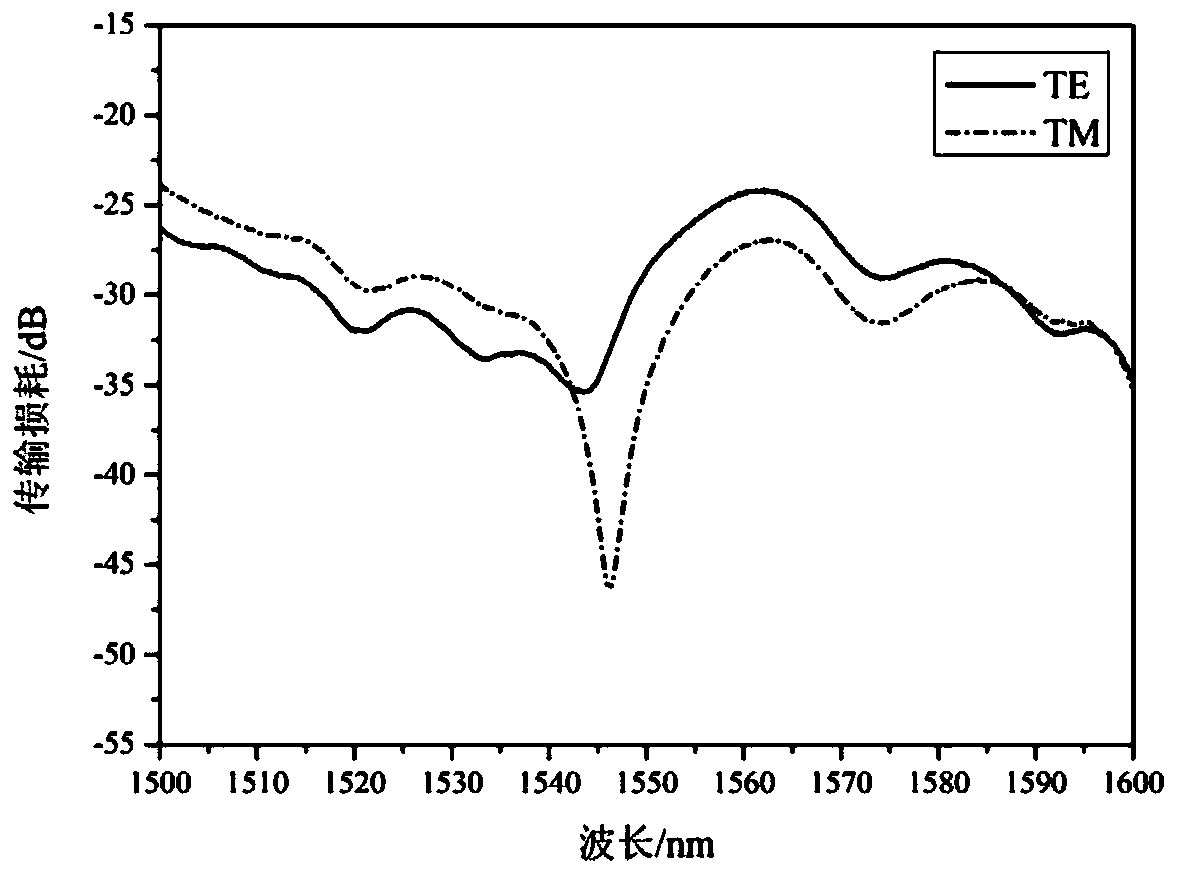

[0022] Table 1 Processing parameters and test results of 3 examples of the present invention.

[0023] Sample serial number Example 1 Example 2 Example 3 Polishing Depth (μm) 20 20 20 Polishing Angle(°) 85 65 45 Extinction ratio(dB) 13 7.5 4

[0024] Three embodiments all adopt identical processing mode, and its concrete preparation process is as follows:

[0025] ① Briefly handle the optical fiber to be processed. First peel off the coating layer of the optical fiber to be processed, and then use a dust-free paper dipped in a small amount of alcohol to wipe off the remaining coating debris on the surface of the optical fiber;

[0026] ②Install sandpaper with appropriate roughness on the rollers of the polishing equipment according to actual needs, and ensure that the san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com