Numerical control 6-station automatic sizing quenching press

A quenching press and six-station technology, applied in the direction of quenching devices, manufacturing tools, furnace types, etc., can solve the problems of long press quenching process, hinder production efficiency, low working frequency, etc., achieve small footprint, improve Production efficiency and energy saving effect

Inactive Publication Date: 2011-01-05

TIANJIN HEAT TREATMENT INST

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the development of modern production process, this stand-alone stereotyped quenching production line, due to the long time of press quenching process and low working frequency, (only 60-65 pieces / hour, daily output is only 1200-1300 pieces) wastes energy consumption, seriously impedes the improvement of production efficiency

Relevant information shows that only one clutch manufacturing company in Hangzhou has an annual output of 19 million pieces of diaphragm springs. If calculated according to 20 hours a day, its daily output is about 6,000 pieces, and the production line in the form of a single machine cannot meet the needs at all.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

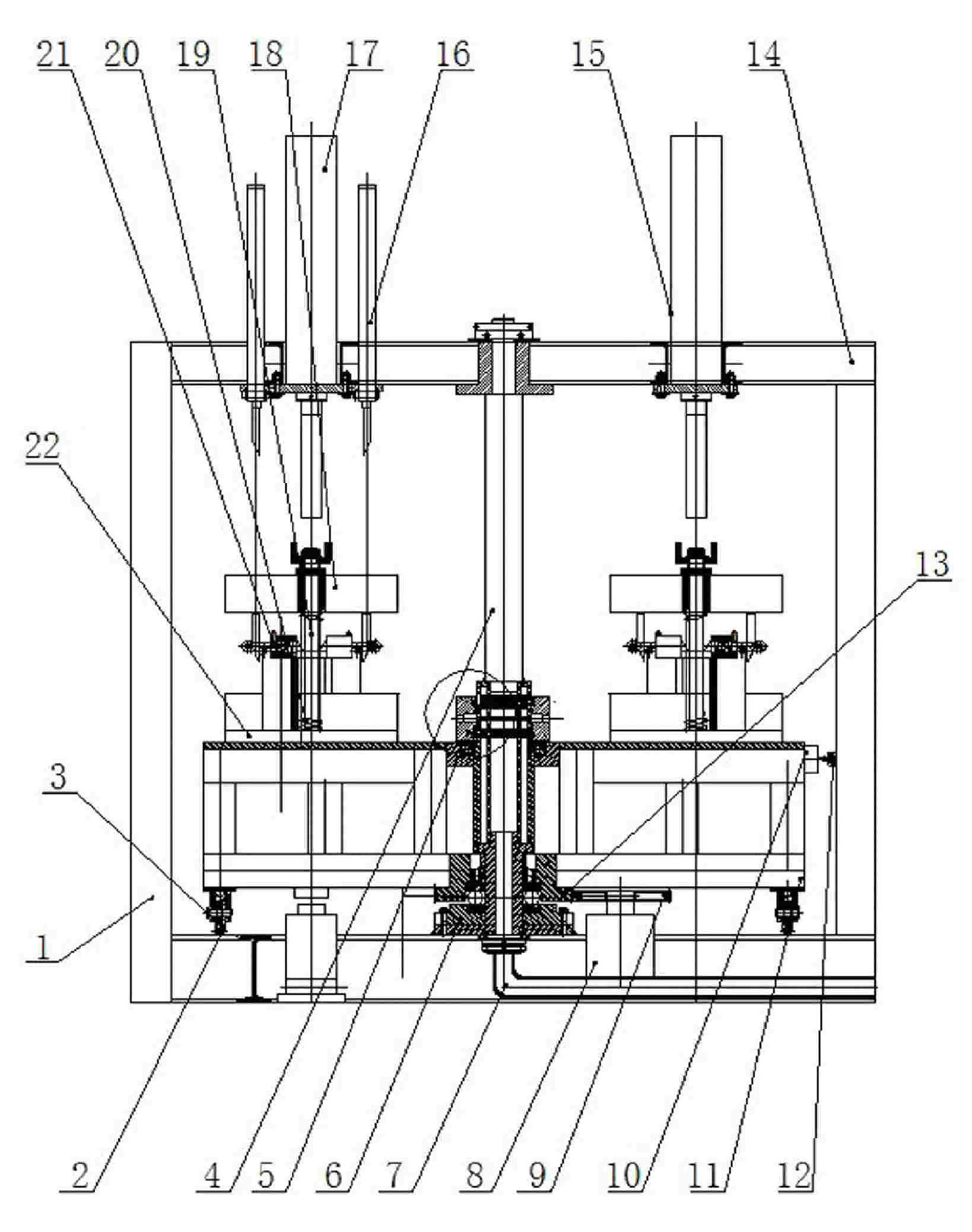

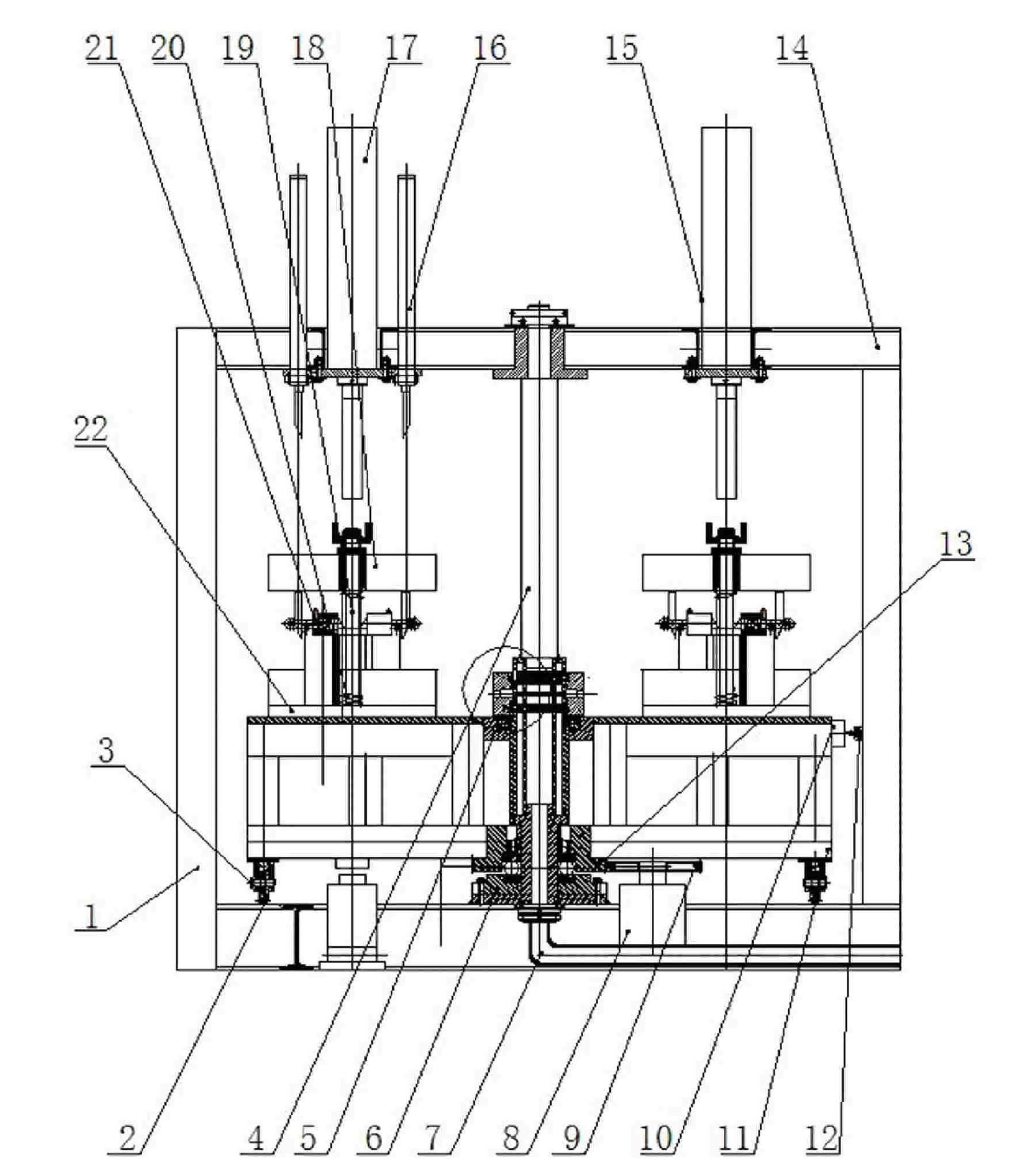

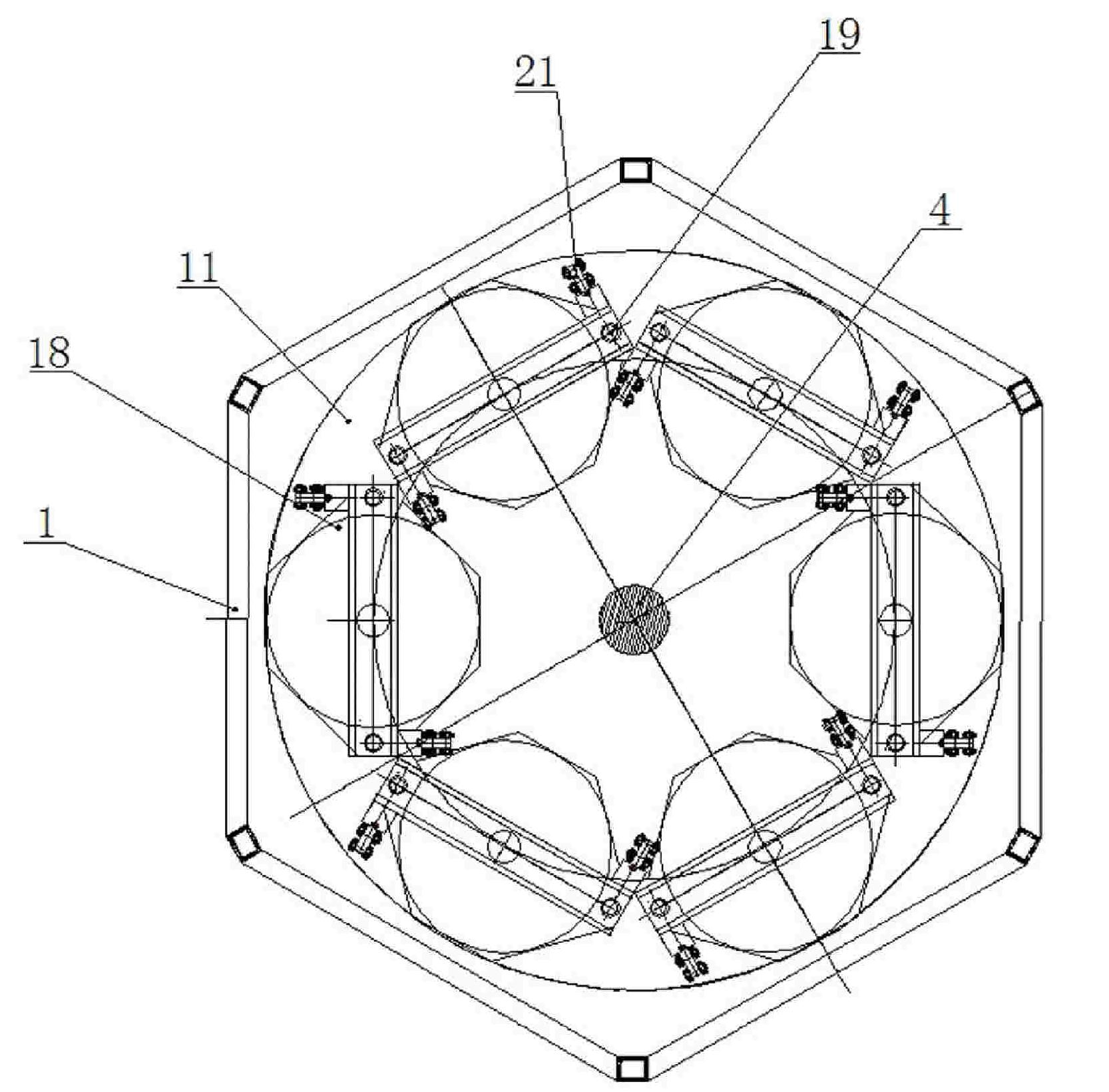

The invention relates to a numerical control 6-station automatic sizing quenching press which is characterized by comprising a hexagonal prism-shaped space framework, wherein the framework is internally and vertically provided with a hollow central rotating shaft, and the hollow central rotating shaft is provided with a rotary working table driven by a hydraulic motor; six pressure quenching moulds respectively with a guide post are uniformly distributed on the rotary working table; the hollow central rotating shaft is provided with an oil injection integrated block capable of providing cooling oil for the pressure quenching moulds; the bottom end of the central rotating shaft is connected with a cooling oil conveying pipe; the edge of the rotary working table is provided with a reversal valve used for controlling the injection of the cooling oil; and the inner side of the framework is correspondingly provided with a convex-concave track used for controlling the on-off of the reversalvalve. Each pressure quenching mould is provided with a locking device, and the guide post of each pressure quenching mould is provided with a return spring. The framework is respectively provided with a mould closing oil cylinder and an opening oil cylinder which correspond to the pressure quenching mould in the first station and the pressure quenching mould in the fifth station, and the framework is also provided with an opening ejector rod and a cylinder thereof which correspond to the locking device of the pressure quenching mould in the fifth station. The invention greatly improves the efficiency of the quenching press and also has the advantages of small occupation area, less investment and energy saving.

Description

CNC six-station automatic shaping quenching press technical field The invention relates to a quenching press used for heat treatment of thin-plate workpieces, in particular to a numerical control six-station automatic shaping quenching press. Background technique At present, the automatic shaping and quenching technology of workpieces such as diaphragm springs, clutch friction plates, and diamond saw blade substrates in the heat treatment industry at home and abroad has been widely used. Known quenching press structure: generally be made up of a hydraulic press, mold and cooling device of a station. The operation process is: the manipulator takes out the heated workpiece from the heating furnace and puts it in the mold for stereotype quenching. In the setting quenching, periodic work. It can be seen that, when the previous workpiece was subjected to type quenching, other workpieces in the heating furnace had already been heated and were in a waiting state. With the deve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D1/673C21D9/46C21D11/00

Inventor 宋宝敬刘香国邢志松姚丙南刘树仁王宝平

Owner TIANJIN HEAT TREATMENT INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com