Front-end double pressure heat absorbing and heat returning circulating thermal system for thermal generator set

A thermal power unit and heat recovery cycle technology, applied in mechanical equipment, steam engine devices, machines/engines, etc., can solve the problems of high coal consumption rate for power generation and low cycle thermal efficiency, and achieve the goals of reducing coal consumption for power generation, saving resources, and improving cycle thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

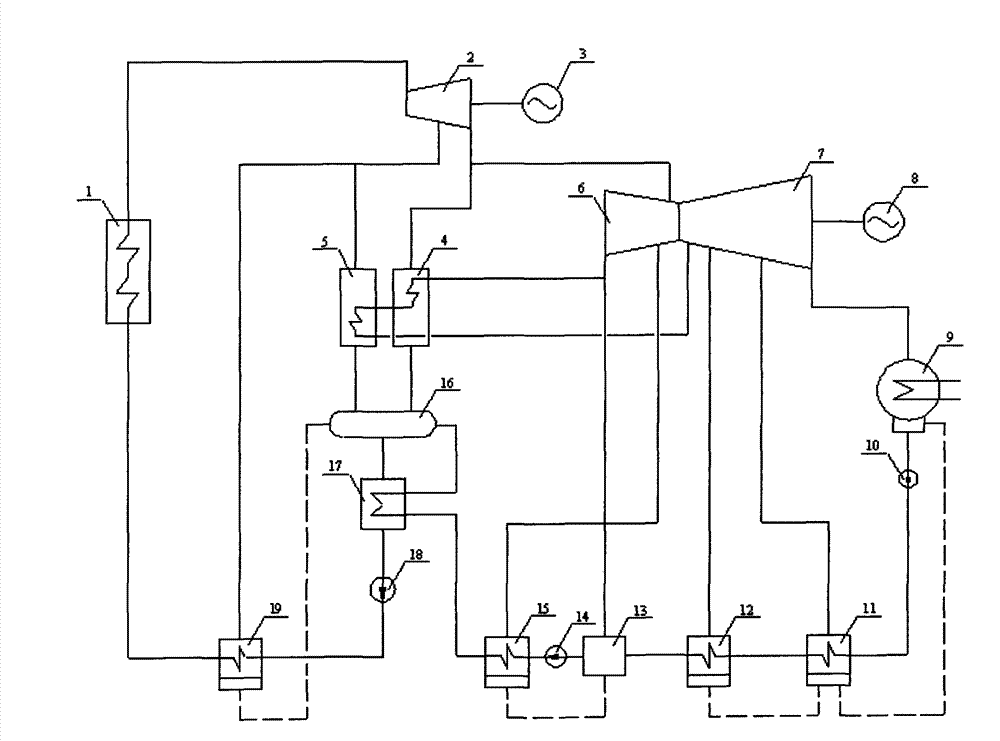

[0009] Such as figure 1 The schematic diagram of the dual-pressure heat absorption heat recovery cycle thermal system of the front thermal power unit shown, the system includes a boiler 1, a front steam turbine 2, a front generator 3, a low-temperature steam reheater 4, and a high-temperature steam reheater 5 , steam turbine cylinder 6, 7, generator 8, condenser 9, condensate pump 10, low pressure heater group 11, 12, deaerator 13, secondary feed water pump 14, high pressure heater 15, preheater 16, Water-to-water heat exchanger 17, primary feed water pump 18 and front auxiliary high pressure heater 19 (abbreviated as front auxiliary high pressure heater).

[0010] The superheated steam generated by the boiler 1 enters the front steam turbine 2 to do work, and the extracted steam is divided into two streams, one stream enters the front auxiliary heater 19, and the other stream enters the high-temperature steam reheater 5, where the high-temperature reheated steam is heated and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com