Non-plug-in shaft torque measuring device

A measuring device and shaft torque technology, applied in the field of non-insertion shaft torque measuring devices, can solve the problems of high sensitivity requirements of strain gauges, influence of measurement accuracy, mass eccentricity, etc., to reduce costs, improve accuracy, and improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

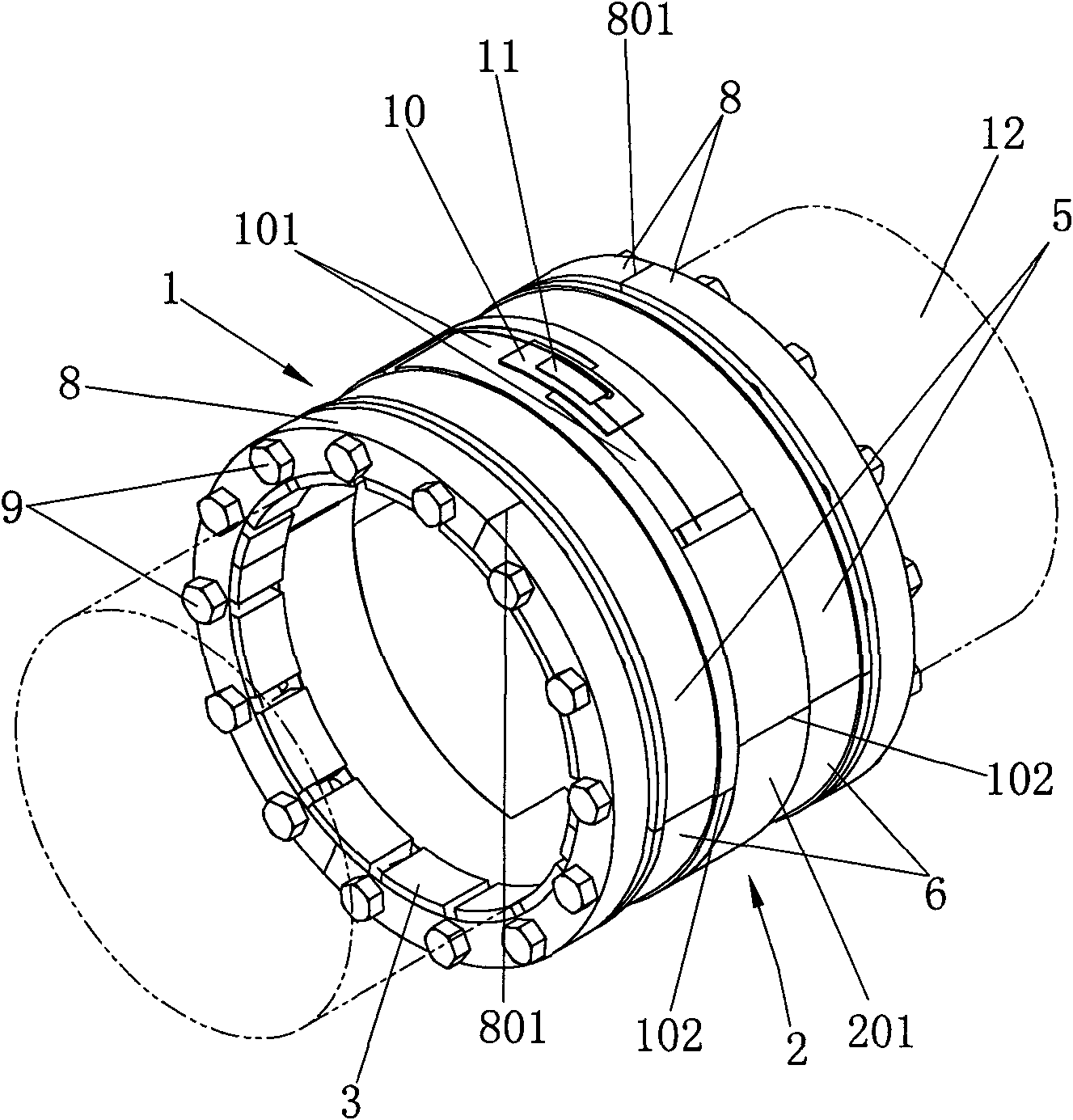

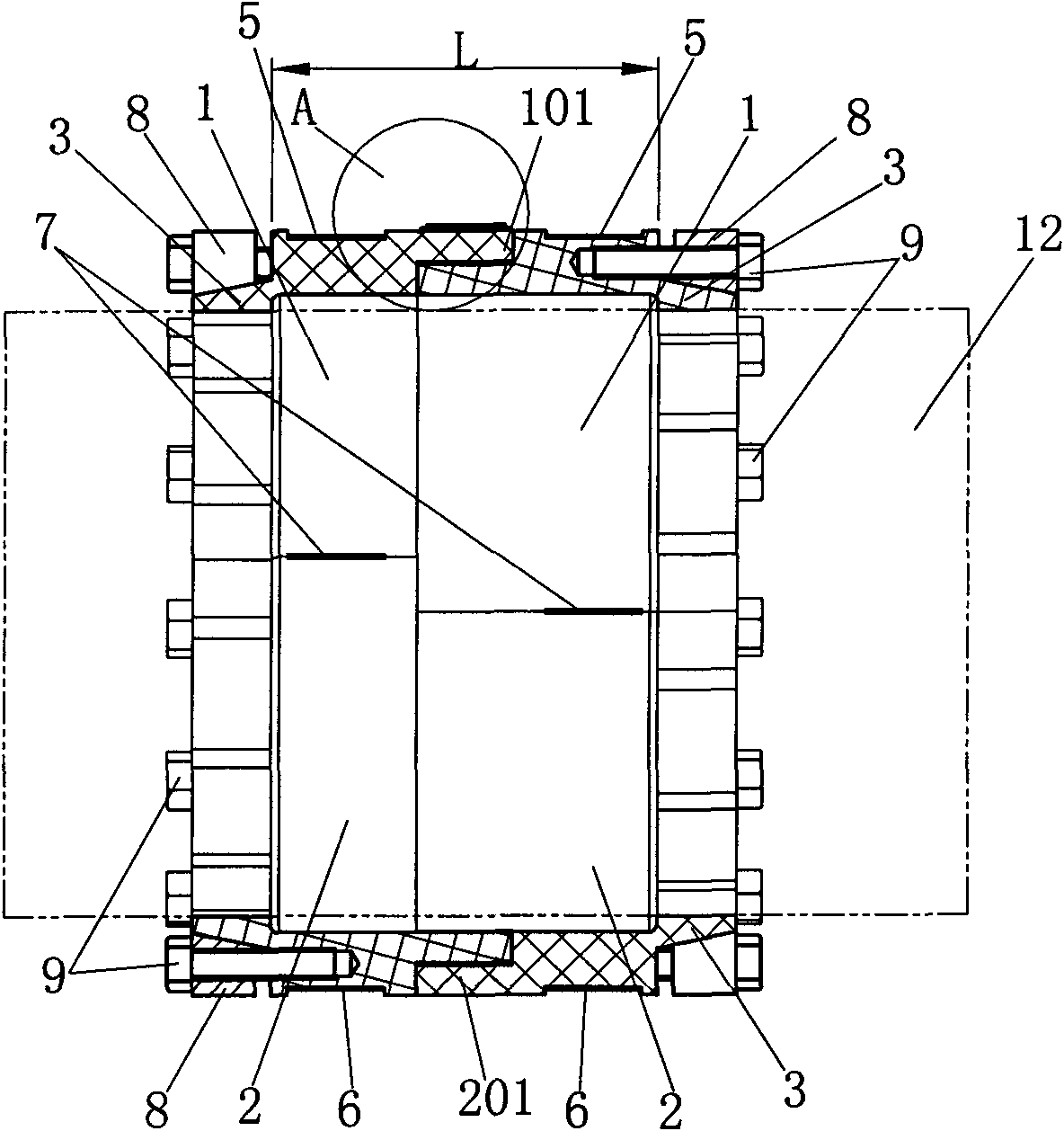

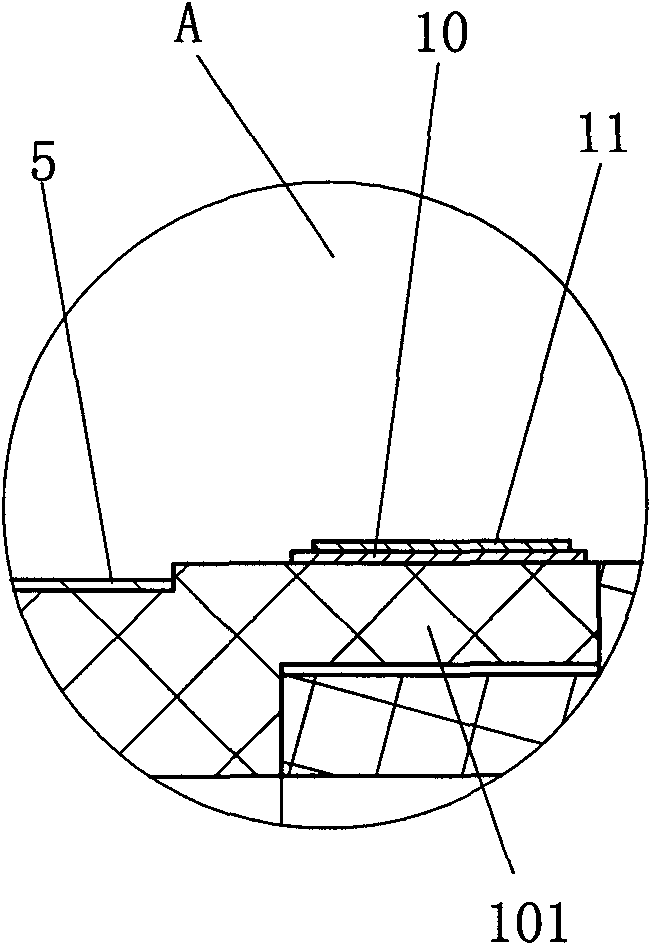

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] Such as Figures 1 to 8 Shown, the present invention comprises two main measuring arms 1 and two auxiliary measuring arms 2, and they are made of insulating material, as engineering plastics or nylon, and main measuring arm 1 and auxiliary measuring arm 2 are semi-circular, and main measuring arm 1 The inner side is provided with an inner edge 101 accounting for one quarter of the circumference, the inner side of the auxiliary measuring arm 2 is provided with an inner edge 201 accounting for one quarter of the circumference, and the outer side of the main measuring arm 1 and the auxiliary measuring arm 2 is provided with an outer edge 3 , the outer surface of the outer edge 3 is a conical surface, and the outer edge 3 is equally divided into a tooth shape by a plurality of longitudinal grooves 301 . When in use, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com