Transformer, bobbin bracket and backlight module using the transformer

A winding frame and transformer technology, applied in the direction of transformer/inductor core, transformer/inductor coil/winding/connection, components of lighting devices, etc., can solve the problems of tension adjustment cost, complex production process of transformer, and many Time and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

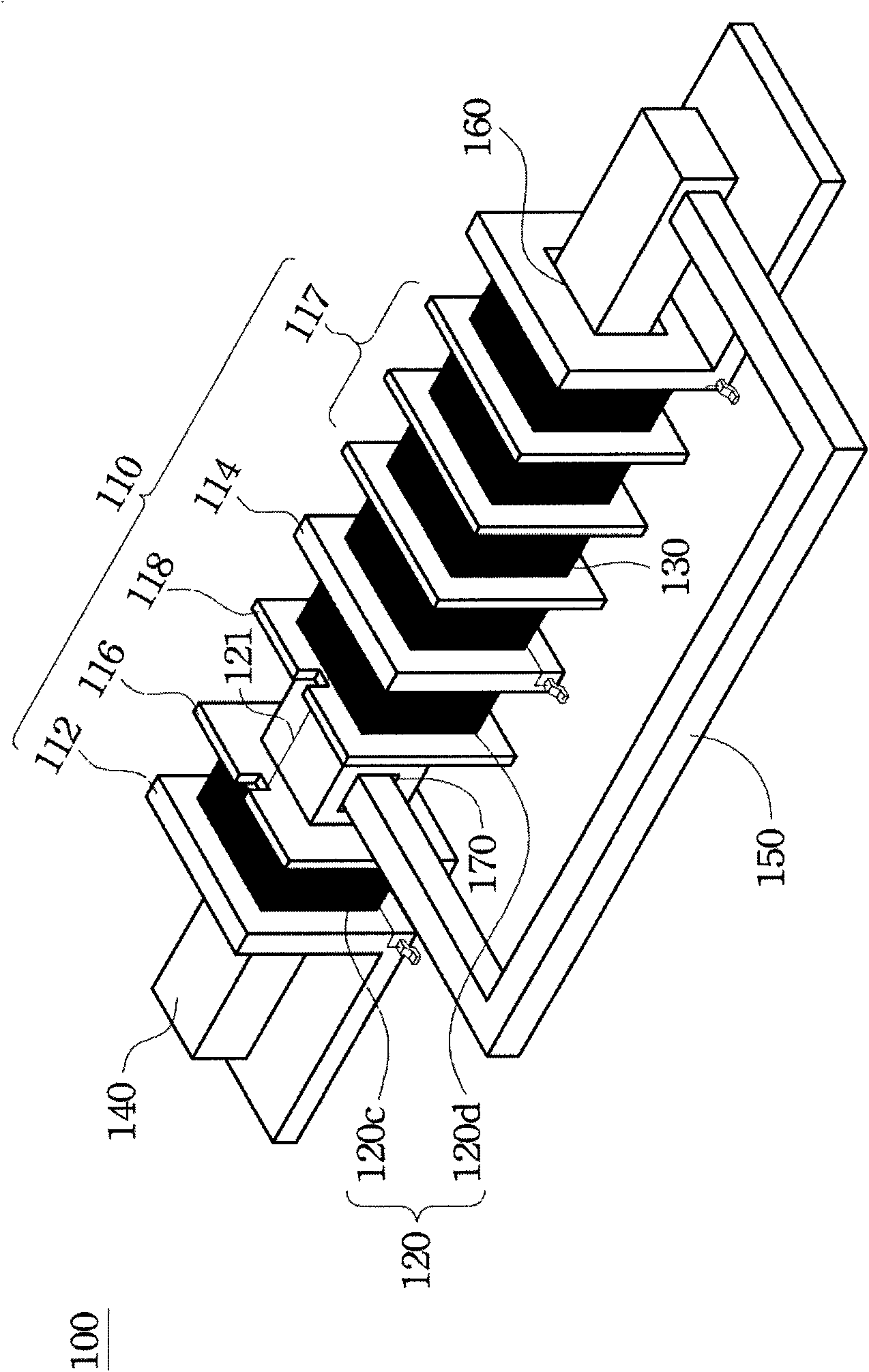

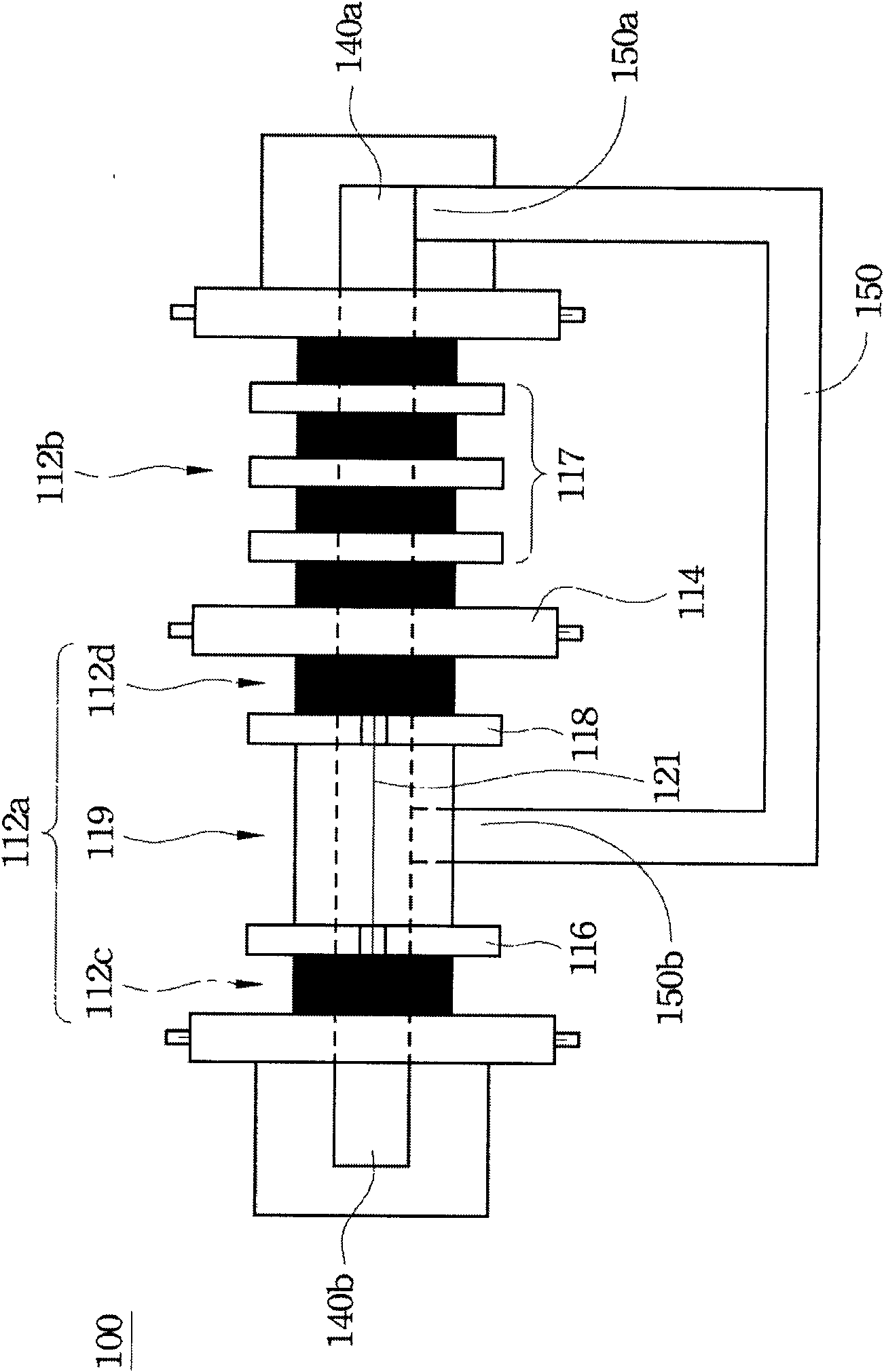

[0081] Embodiment one: see attached figure 1 , attached Figure 1A ,

[0082] A transformer 100 includes a bobbin 110 , a primary winding 120 , a secondary winding 130 , and a first magnetic core 140 and a second magnetic core 150 . The bobbin frame includes a main body 112, a first partition 114, two second partitions 116, 118 and a partition 117, wherein the main body 112 is provided with an accommodating space in the axial direction for accommodating the first Magnetic core 140 . In this embodiment, the accommodating space is the through hole 160 passing through the main body 112 , and the first magnetic core 140 is placed in the through hole 160 passing through the main body 112 , but the invention is not limited thereto.

[0083]The first separator 114 is disposed on the main body 112 perpendicular to the axial direction of the main body 112 , and divides the main body 112 into a primary winding slot 112 a and a secondary winding slot 112 b. The separator 117 is locat...

Embodiment 2

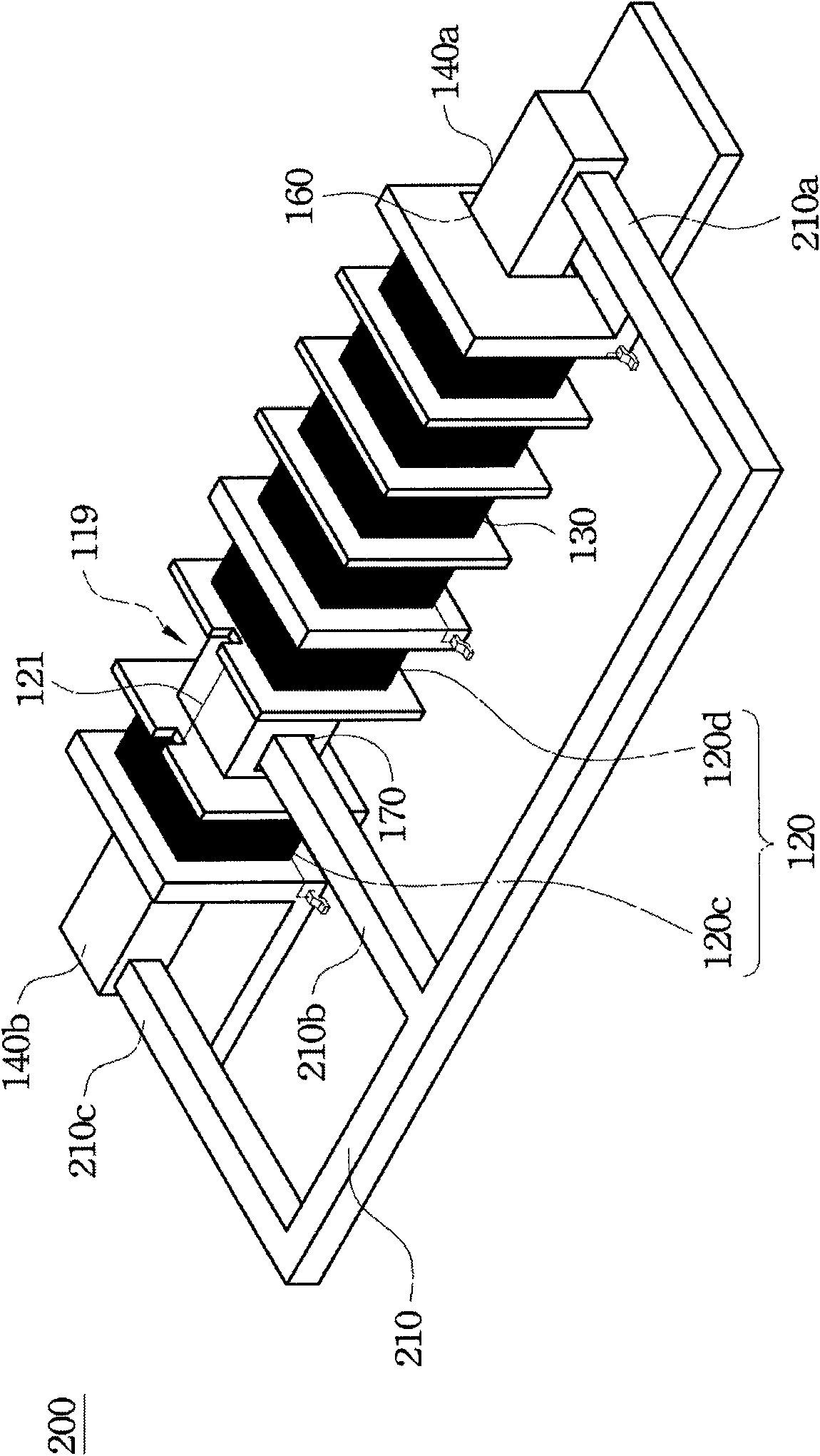

[0090] Embodiment two: see attached figure 2 as shown,

[0091] A transformer 200, which is different from the transformer 100 of Embodiment 1 in that: the second magnetic core is a magnetic core 210, which has three magnetic core ends 210a, 210b and 210c, wherein the magnetic core end 210b is inserted into To the first intervening space 119 , the magnetic core end 210 a is coupled to the magnetic core end 140 a of the first magnetic core 140 , and the magnetic core end 210 c is coupled to the magnetic core end 140 b of the magnetic core 140 . It can be known from the above description that the transformer 200 uses the magnetic core end 210c to couple with the magnetic core end 140b of the magnetic core 140 to change the magnetic circuit of the transformer 200 .

[0092] Others are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0093] Embodiment three: see attached image 3 as shown,

[0094] A transformer 300, which differs from the transformer 100 in Embodiment 1 in that: the second magnetic core is a magnetic core 310, and the magnetic core 310 has three magnetic core ends 310a, 310b and 310c, wherein the magnetic core ends 310b is inserted into the first intervening space 119, the magnetic core end 310a is coupled to the magnetic core end 140a of the first magnetic core 140, and the magnetic core end 310c extends parallel to the axial direction of the bobbin. It can be known from the above description that the magnetic core end 310 c of the transformer 300 extends outward parallel to the axial direction of the bobbin, so as to change the magnetic circuit of the transformer 100 .

[0095] Others are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com