Encapsulating method of colour loop inductance product

A technology of inductance and products, which is applied in the field of encapsulation of leaded electronic components, can solve the problems of increased pinhole and air bubble rate, easy disconnection of enameled wire, and low production efficiency, so as to increase tensile strength and improve Encapsulation effect, effect of reducing manufacturing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

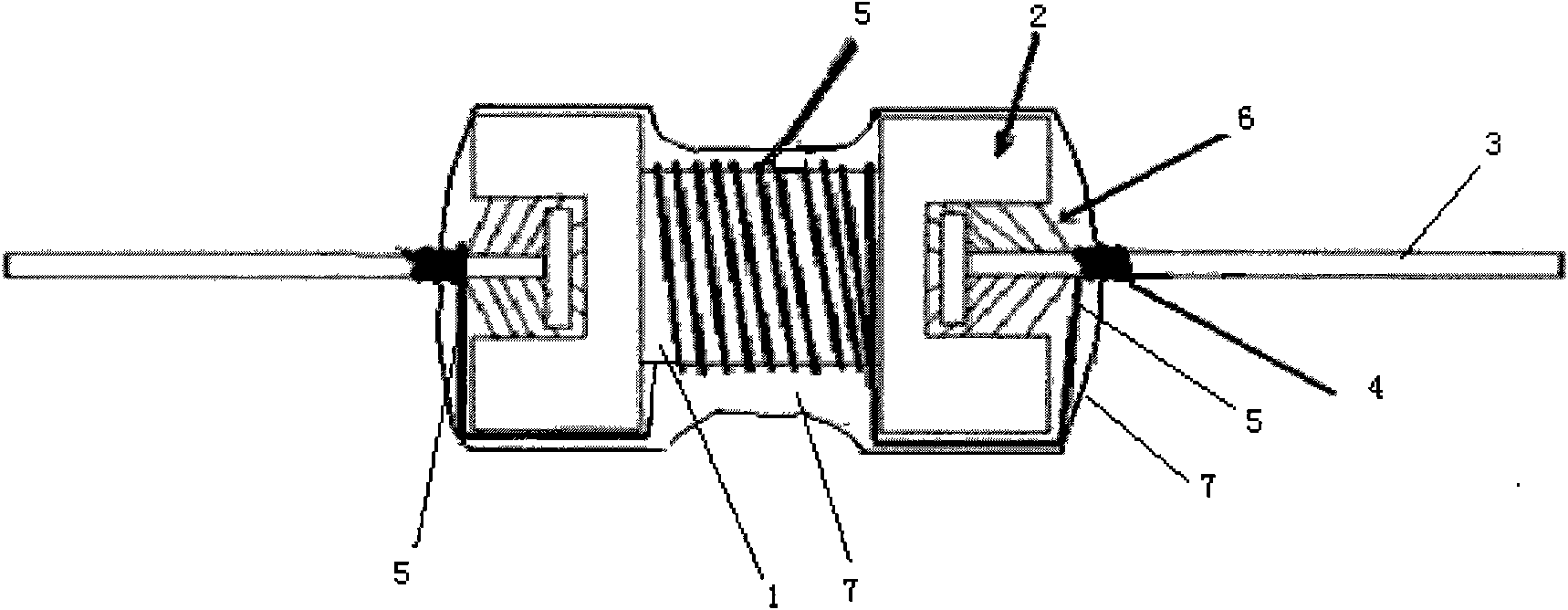

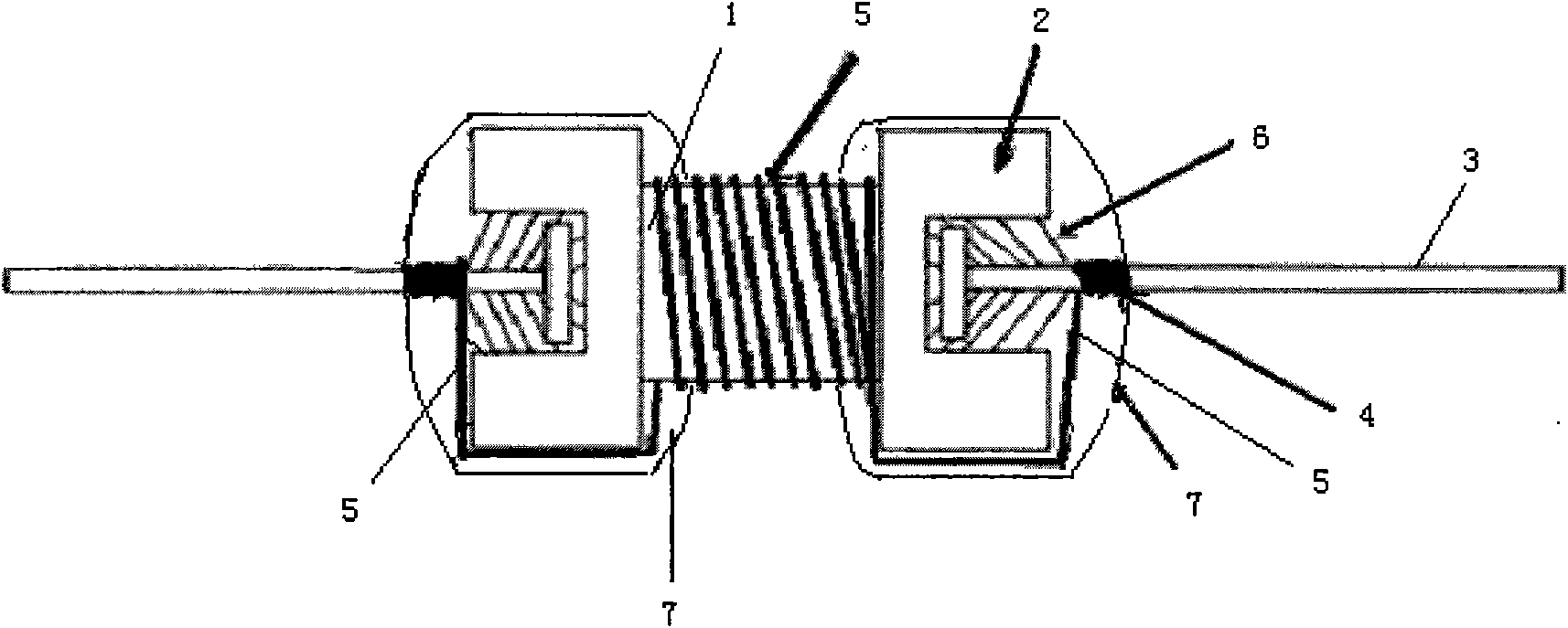

Image

Examples

Embodiment

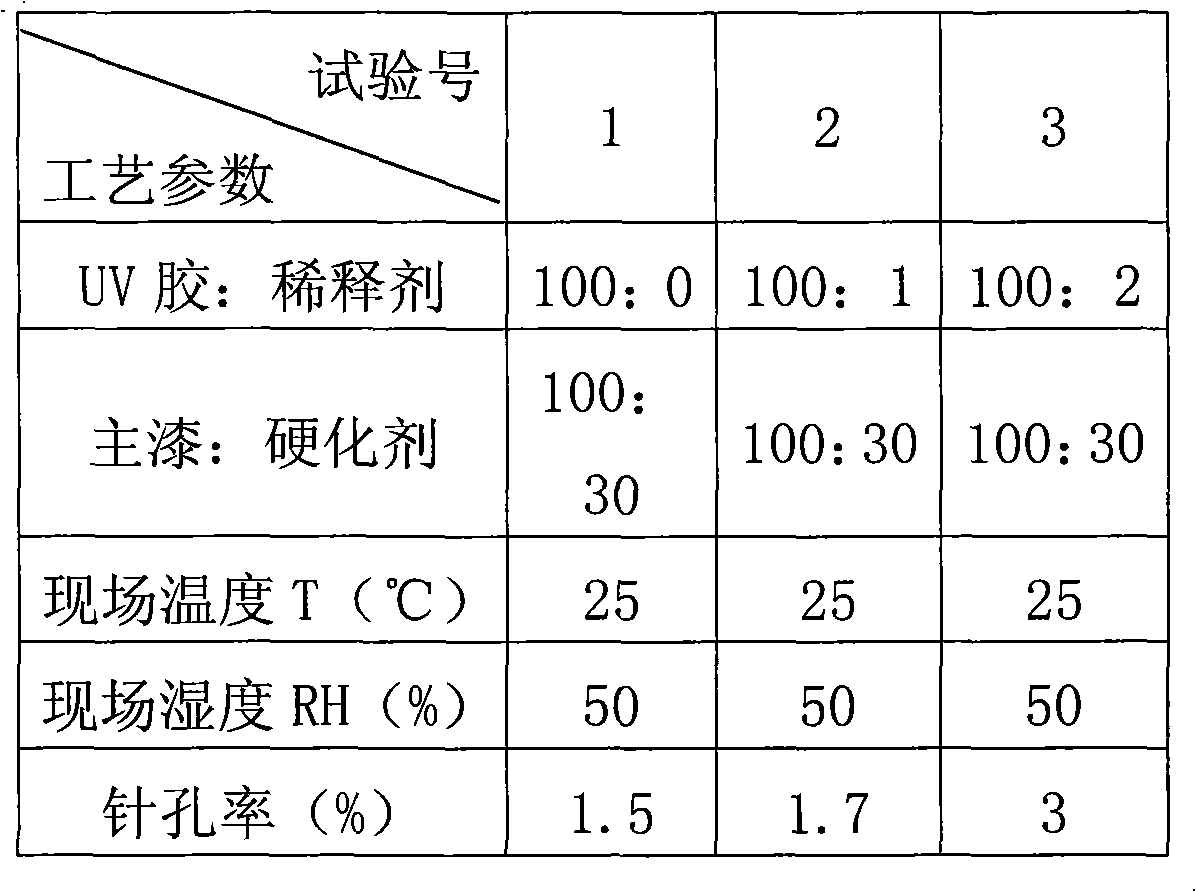

[0028] The first test: choose a weather with a temperature (T) close to 25°C, keep the humidity RH (about 50%) and the ratio of main paint and hardener (100:30), and observe the encapsulation that changes with the ratio of UV glue and thinner Effect, Table 1 is the experimental conditions and results.

[0029] Table 1

[0030]

[0031] The second test: keep the humidity RH (about 50%) and the ratio of main paint and hardener (100:30), and observe the encapsulation effect of adjusting the ratio of UV glue and thinner accordingly as the temperature changes, as shown in Table 2:

[0032] Table 2

[0033]

[0034] The above two experiments show that in order to obtain a good encapsulation effect, the ratio of UV glue and diluent must be changed accordingly according to the on-site temperature. Under the condition that other conditions remain unchanged, the following optimum temperature and its corresponding UV glue must be determined: The diluent ratio is shown in Table 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com