PWM rectification type energy feedback device

An energy feedback and improved technology, which is applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the problem of only considering energy feedback power, increasing the electrical stress of the inverter, and filtering difficulties and other issues, to achieve the effect of reducing volume and switching noise, reducing current harmonic content, and reducing hardware complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

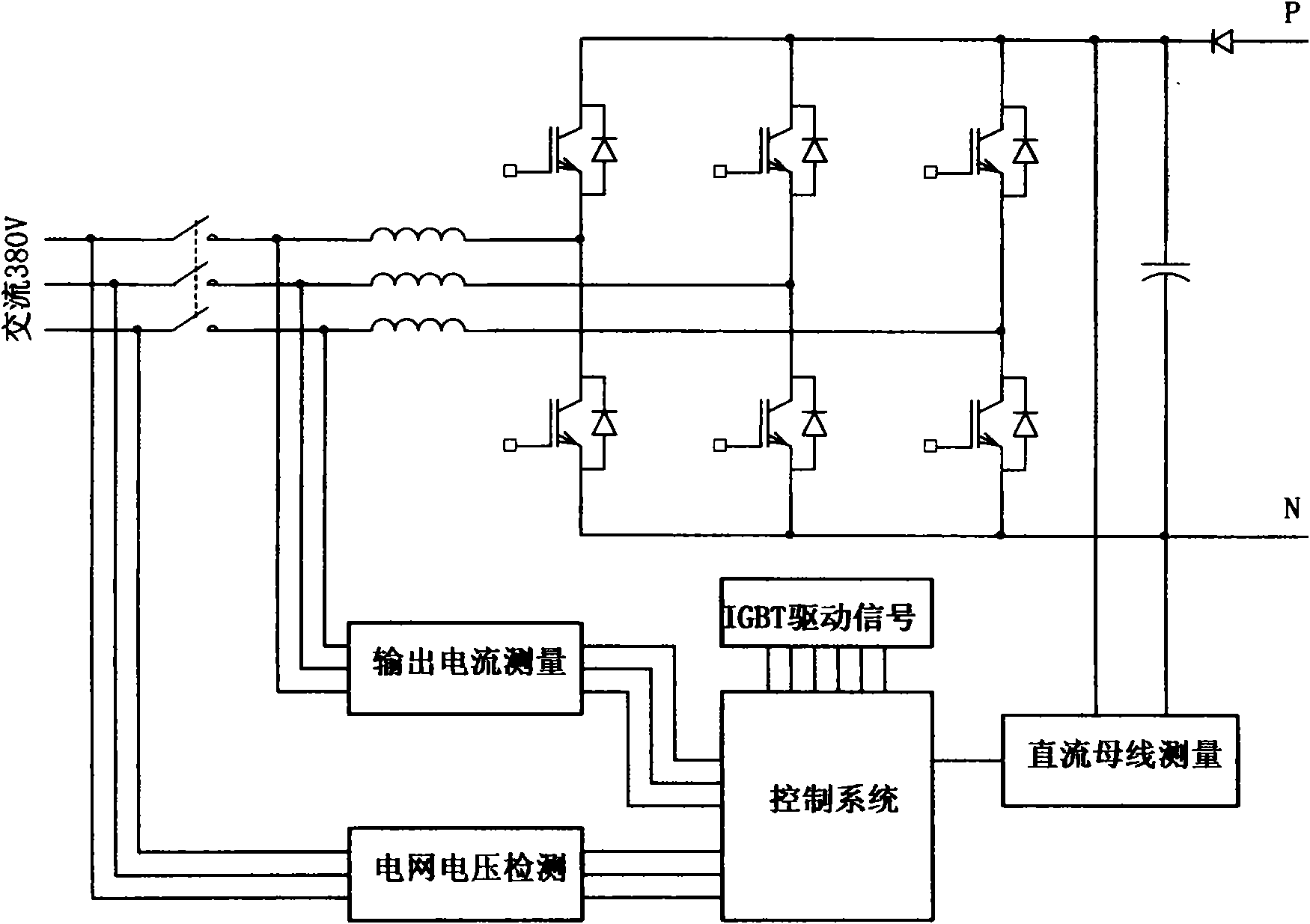

[0014] figure 1 As shown, the main circuit is composed of a three-phase bridge circuit, a grid voltage detection circuit, an output voltage direct detection circuit, a current detection circuit, a drive circuit, and a control circuit.

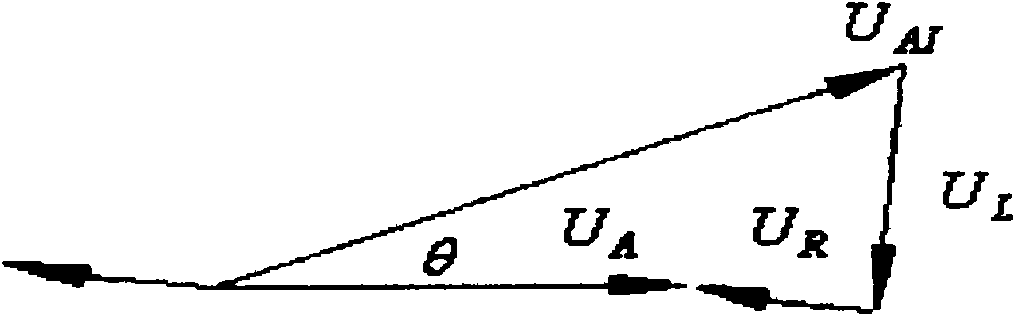

[0015] Such as figure 2 As shown, the phase-amplitude control is based on the steady-state equivalent single-phase phasor diagram. Since the inductance parasitic resistance Rr is small, it can be neglected in engineering. In order to obtain unity power factor inverter, IA is opposite to UA, so UL is perpendicular to UA. Therefore:

[0016] U AI = U A 2 + ( ω LI A ) 2

[0017] θ=arctan(ωL / U A )

[0018] Among them, I dc =f(U dc ), dU dc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com