Semiconductor sealing resin composition and semiconductor device using the resin composition

A resin composition and sealing resin technology, applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as damage to resin curability, and achieve the effect of excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091]

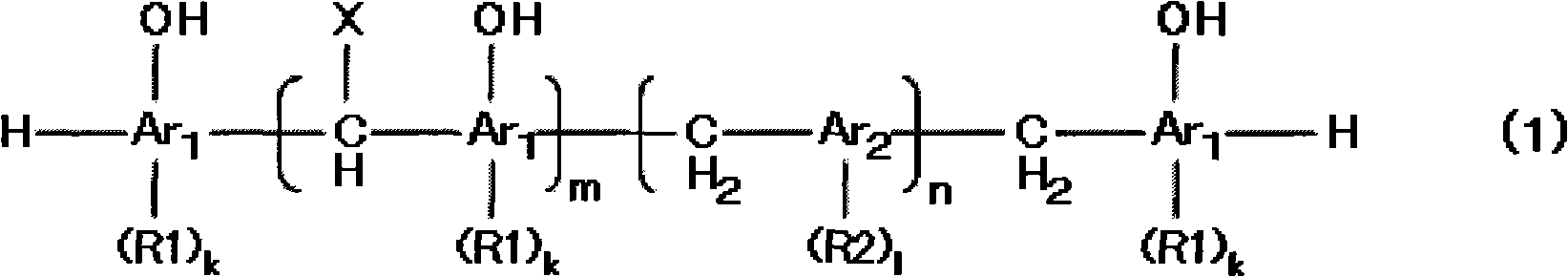

Epoxy resin 1: phenol-aralkyl type epoxy resin (Nippon 7.57 parts by weight) with biphenylene structure

NC-3000 manufactured by Kayaku Co., Ltd., epoxy equivalent: 274; softening point: 58°C)

Compound B1 4.23 parts by weight

Curing accelerator 1: 0.20 parts by weight of triphenylphosphine

Silane coupling agent 1: 0.30 parts by weight of γ-glycidyl etheroxypropyl trimethoxysilane

0.20 parts by weight of 2,3-dihydroxynaphthalene

Fused spherical silica (average particle size: 30 μm) 87.00 parts by weight

Carnauba wax 0.20 parts by weight

Carbon black 0.30 parts by weight

The above ingredients were mixed using a mixer at room temperature. The mixture is melt-kneaded at 80° C. or more and 100° C. or less using a heating roll, cooled, and then pulverized, whereby an epoxy resin composition is obtained. The prepared epoxy resin compositions were evaluated by the following methods. The evaluation results are shown in Table 2.

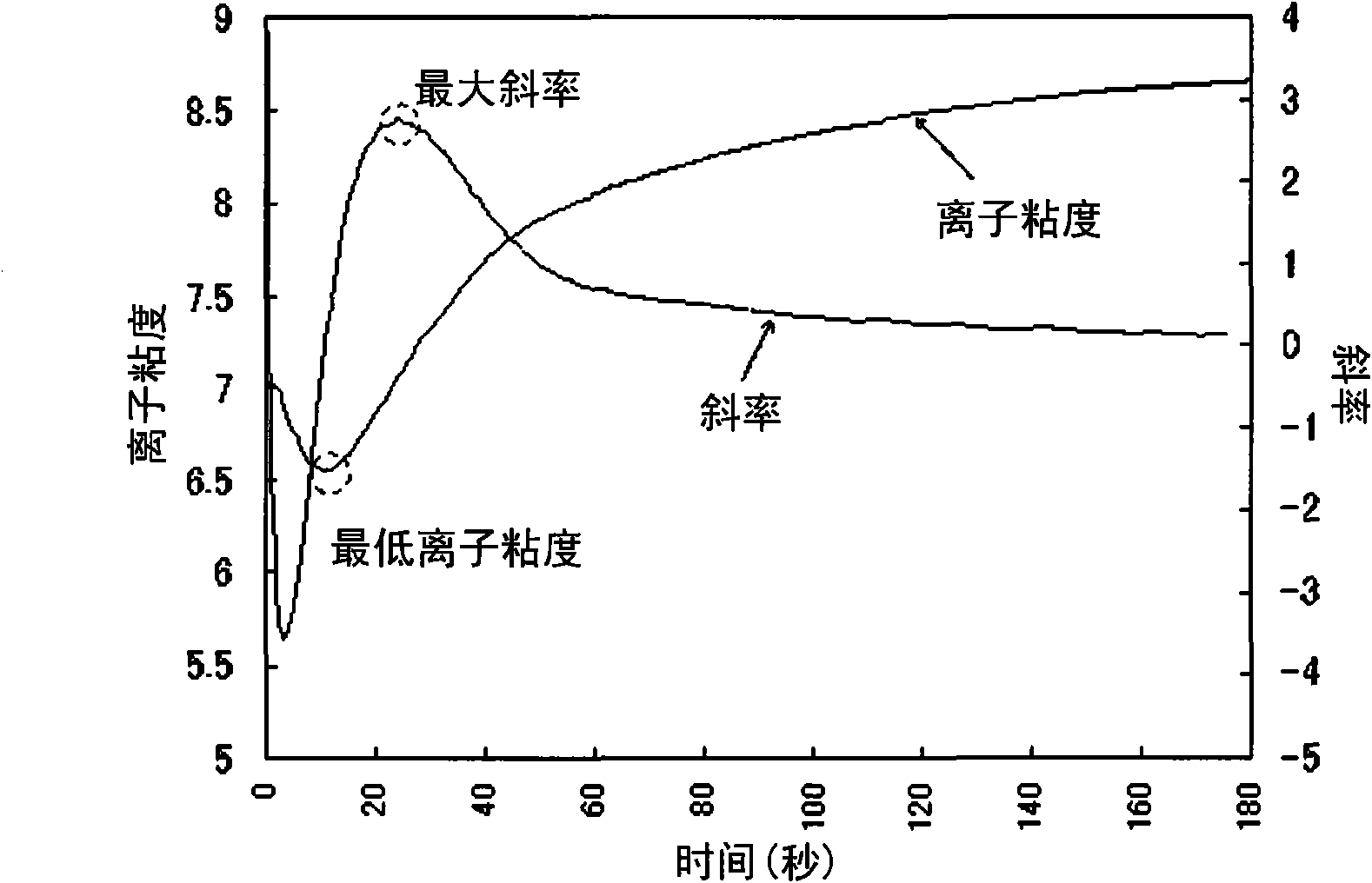

[0092] Spiral flow: Transfer t...

Embodiment 2-24 and comparative example 1-3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com