High-speed vertical glass drilling machine

A drilling machine and glass technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. It can solve the problems of tool collision, low control accuracy, damage to machines and workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

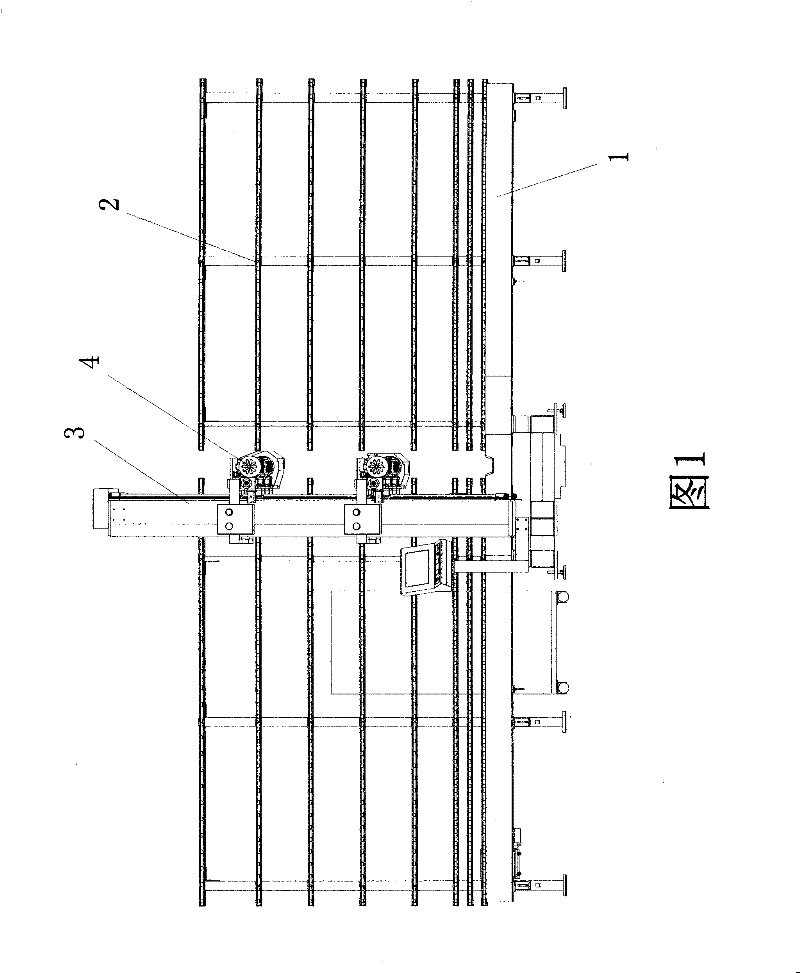

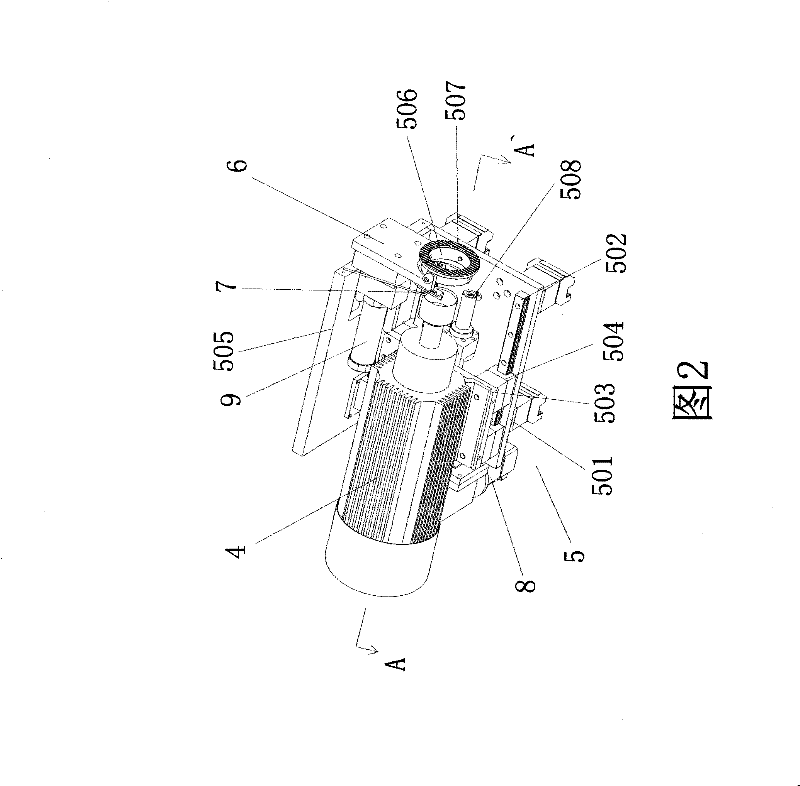

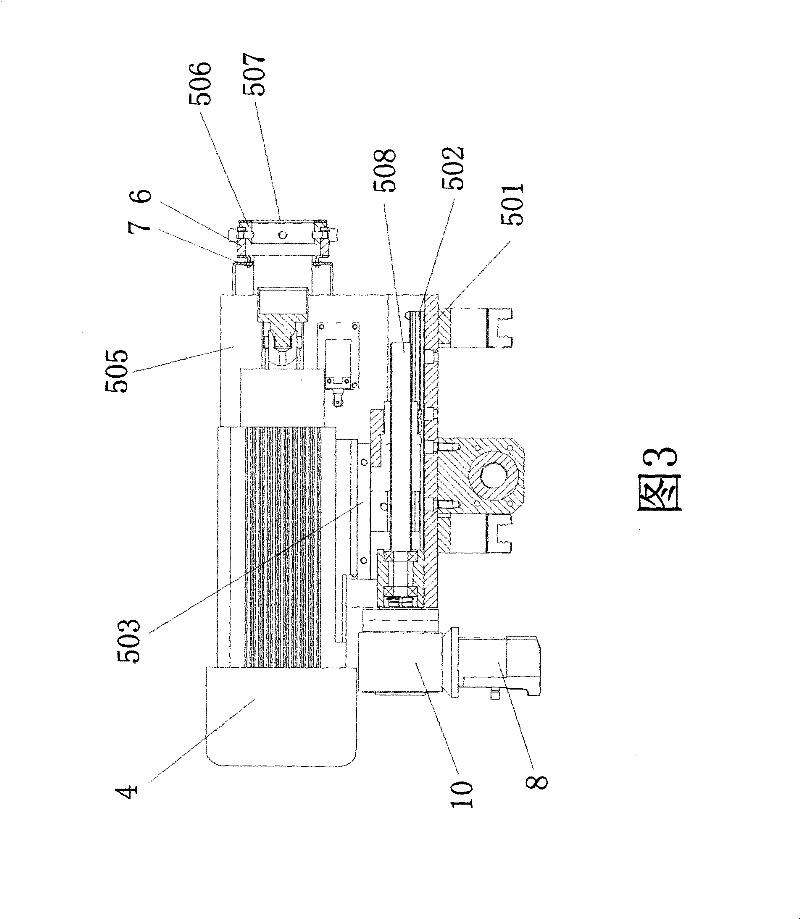

[0020] Such as figure 1 , 2 , 3, including a base 1, a glass frame 2, and a column 3, a drilling motor 4 is respectively arranged on the column 3, and a horizontal movement module 5 is arranged between the drilling motor 4 and the column 3, and the described The drill port of the drilling motor 4 is provided with a splint 6, the splint 6 is provided with a drill feed position induction switch 7, and a servo motor 8 for driving the drilling motor 4 to advance and retreat is also provided between the drilling motor 4 and the horizontal movement module 5. The inductive switch 7 and the servo motor 8 are connected and controlled by a numerical control system, and the inductive switch 7 is a photoelectric switch.

[0021] The column 3 is respectively provided with upper and lower pairs of drilling motors 4, and the upper and lower pairs of drilling motors 4 are coaxial with each other respectively.

[0022] The horizontal moving module 5 is composed of a moving carriage 503 , a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com