Shaping former and device for building green-tire including the same

A molding device and molding machine technology, applied in tires, applications, household appliances, etc., can solve the problems of complex structure and control, large-scale devices, etc., and achieve the effect of simplifying the structure, improving productivity, and reducing idle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, one embodiment of the present invention will be described based on the drawings.

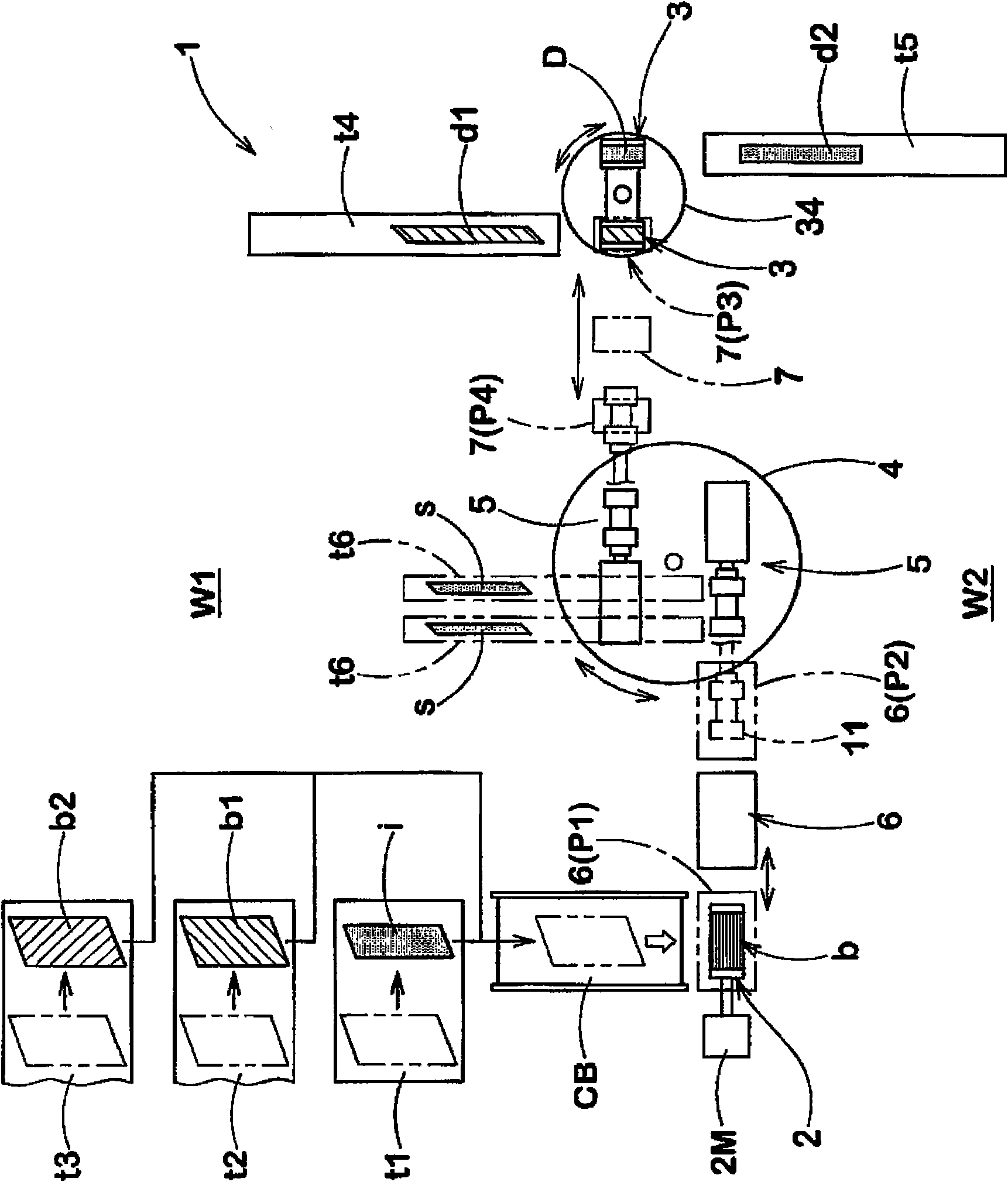

[0042] figure 1It is an overall plan view showing the green tire building apparatus 1 using the building machine of the present embodiment.

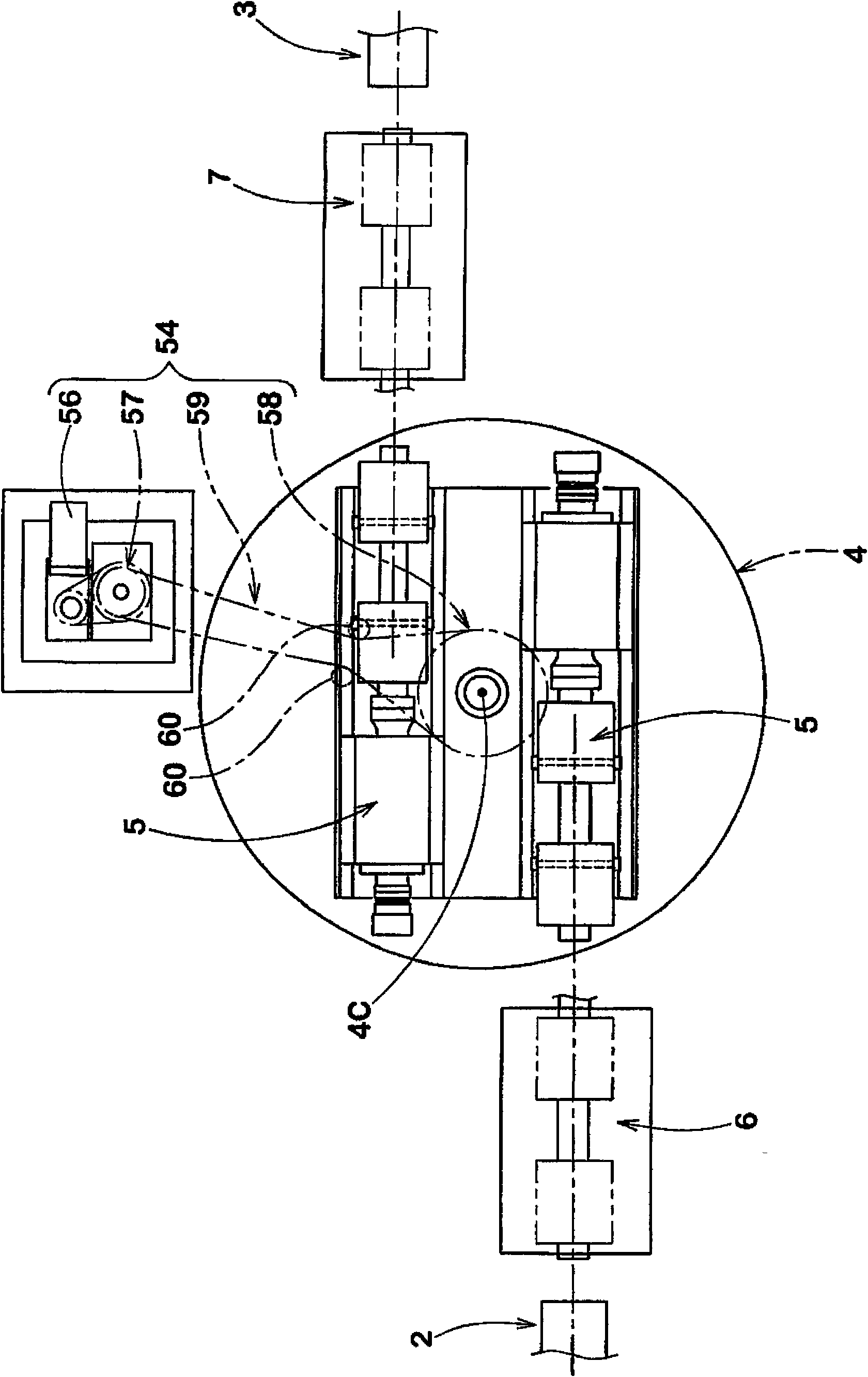

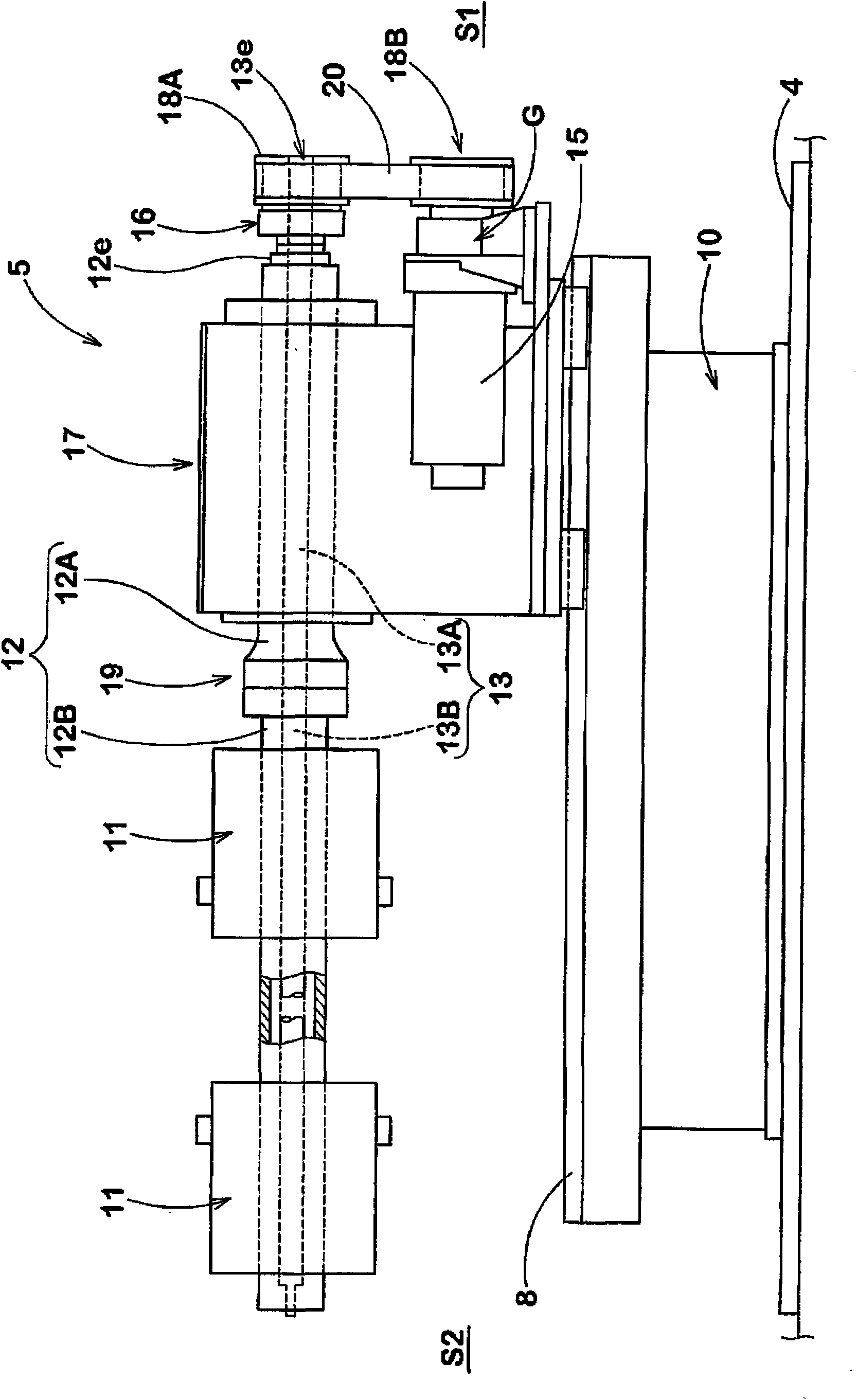

[0043] The structure of the raw tire building apparatus 1 of the present embodiment includes: a cylindrical first drum 2 for forming such as Figure 12 The green tire base B shown; the cylindrical second drum 3, which is used for forming such as Figure 14 The shown tread ring D; the turntable 4, which is provided rotatably about a vertical axis between the first drum 2 and the second drum 3; a pair of (ie, two) molding machines 5 provided on the turntable 4 ; the first conveying device 6, which is arranged between the above-mentioned first drum 2 and the building machine 5, and moves the green tire base B from the first drum 2 to the building machine 5; the second conveying device 7, which is arranged on the forming machine between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com