Orbit-plate bidirectional carrier vehicle

A technology of transport vehicles and track plates, which is applied in the direction of transportation and packaging, vehicles used to carry long goods, motor vehicles, etc., and can solve the problems of moving the center of gravity of the vehicle outward, being unable to drive in both directions, and the frame is easy to tilt and twist. , to achieve the effect of small steering performance and small turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The track slab two-way transport vehicle proposed by the present invention is described as follows in conjunction with the accompanying drawings and embodiments.

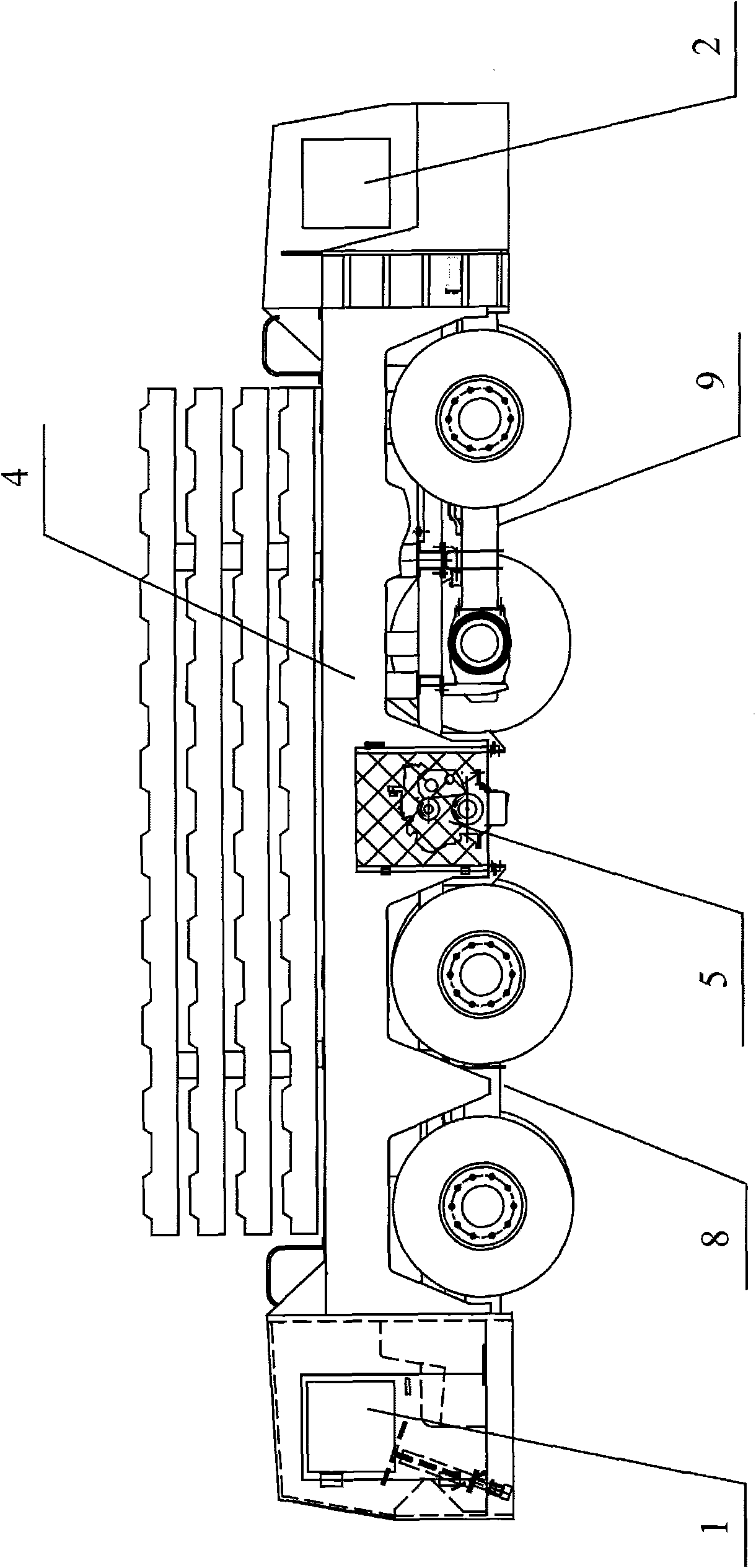

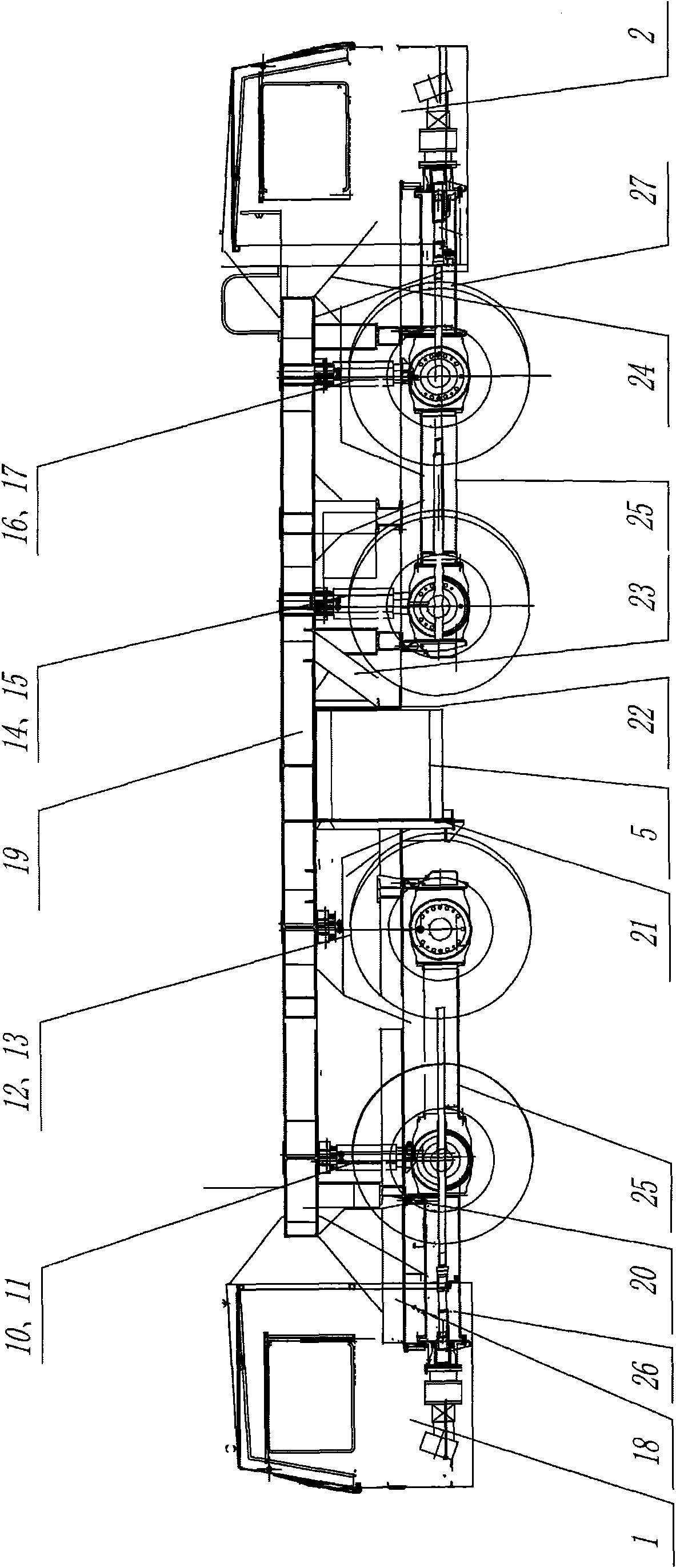

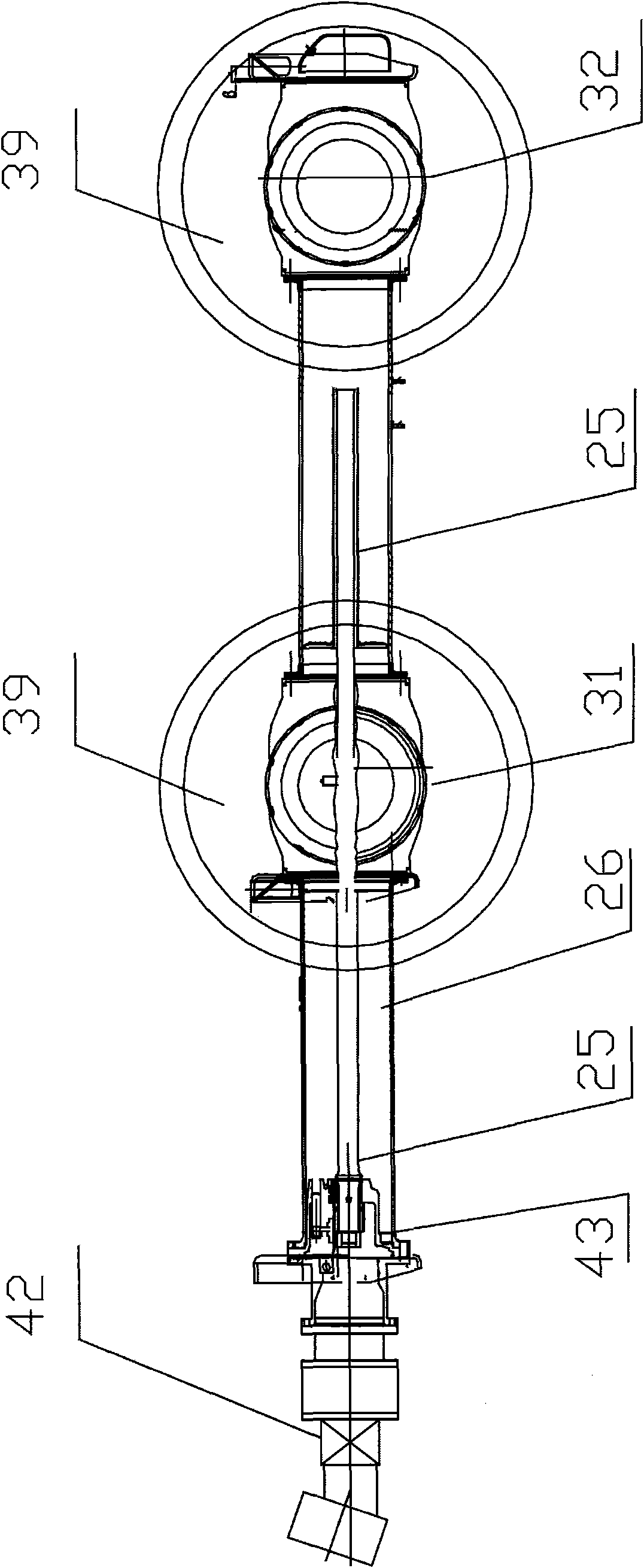

[0032] Such as figure 1 , figure 2 and Figure 4 As shown, a rail slab two-way transport vehicle according to the present invention includes: cabs 1 and 2, running system, vehicle frame 4, power pump station 5, steering system and balance oil cylinder system, wherein cabs 1 and 2 are respectively located in the transport The front and rear ends of the car are used to open and control the entire transport car, so that it can run in both directions, and the track plate can be transported without turning around and reversing. The frame 4 is located at the upper part of the running system, the power pump station 5 is located in the middle of the transport vehicle, the steering system includes the front axles 31 and 34 of the running parts 8 and 9, the lever mechanisms 37 and 38 and the steering cylinders 35 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com