Integration scheme and platform between heterogeneous workgroup collaborative design system and PLM system

A technology for platform and design data, applied in computing, instrumentation, data processing applications, etc., can solve problems such as unsatisfactory remote collaborative design of large and complex products, weak data management, etc., achieve simple and standardized processes, reduce workload, and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

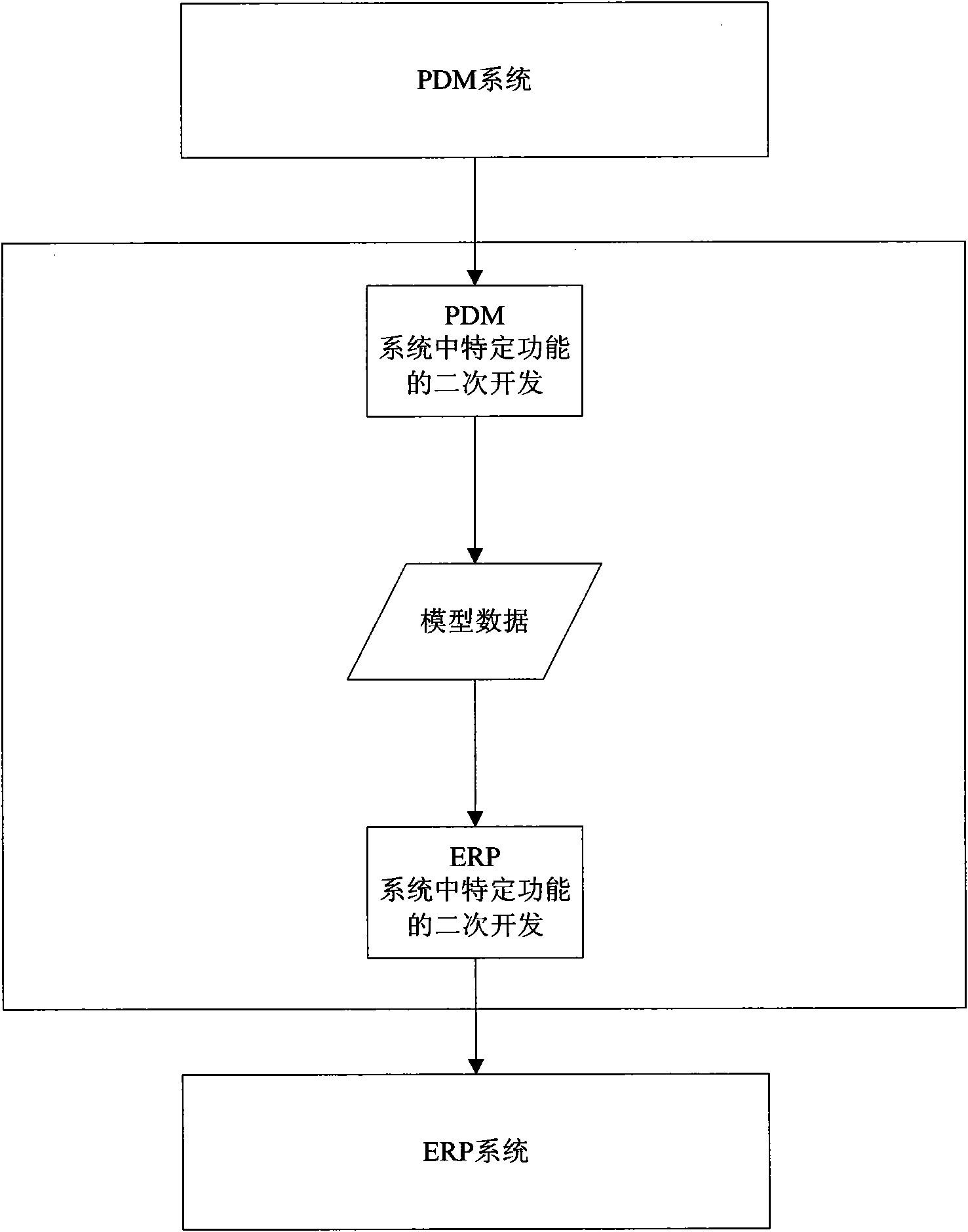

[0045] The specific problem to be solved by the present invention is that when engineers design a three-dimensional model, they need to use the PDM system to realize process collaboration; and when the design is completed, they need to be released to the ERP system for MRP calculation. If engineers rely on manual methods to read the model and its structural information, and then create the corresponding materials, vouchers, and EBOM in the ERP system, it will disperse a lot of energy from the designer, making the work cumbersome and error-prone. At the same time, The process is not easy to manage, it seems chaotic and disorganized. Through this interface, the data information is automatically operated in sequence to achieve the set goal and avoid a lot of manual operations.

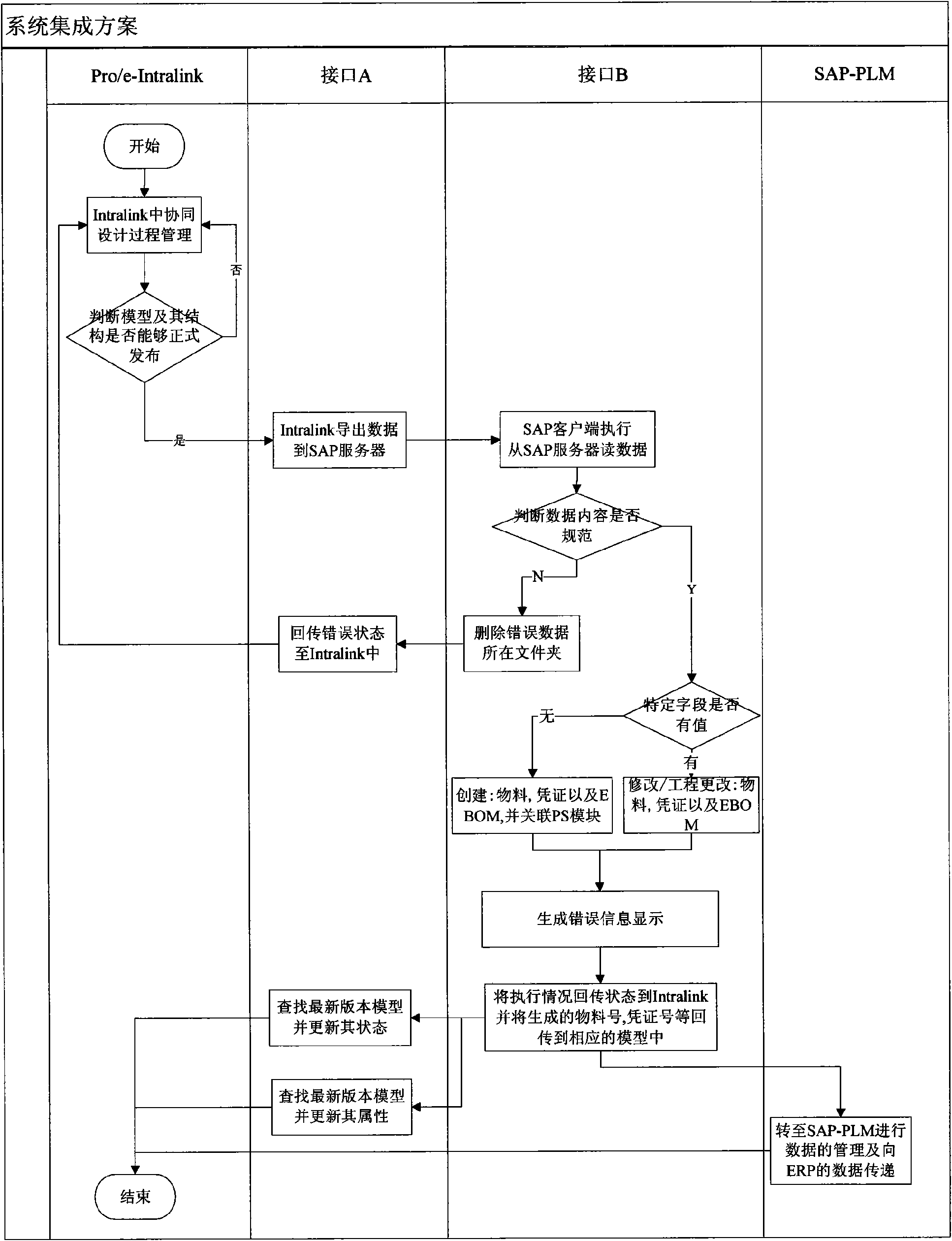

[0046] combine figure 2 , the detailed steps described in the present invention are as follows:

[0047] Step 1. Customize the format of the exported data. Write source codes in the PDM system for sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com