Method for removing support positioning structure of irradiation monitoring pipe

A technology for irradiating supervision tubes and supporting positioning, which is applied in the directions of reactor fuel elements, reactors, and greenhouse gas reduction. It can solve problems such as lack of fixation of sample tubes, rupture of sample tubes, and threats to safe operation, so as to reduce foreign objects falling into refueling. Risks of pools, control of usage costs, effects of reducing radiation doses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for dismantling the supporting and positioning structure of the irradiation supervisory tube according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

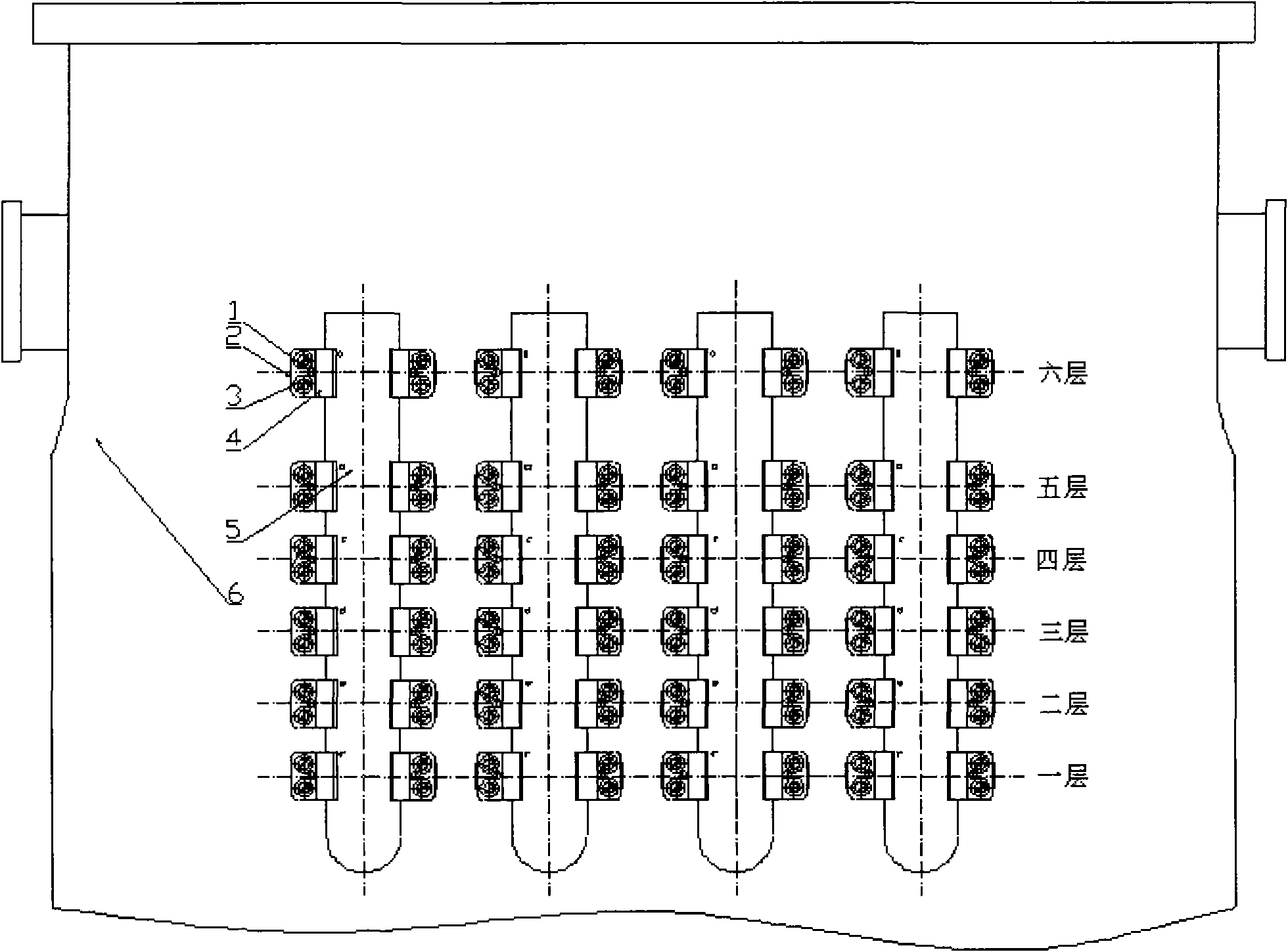

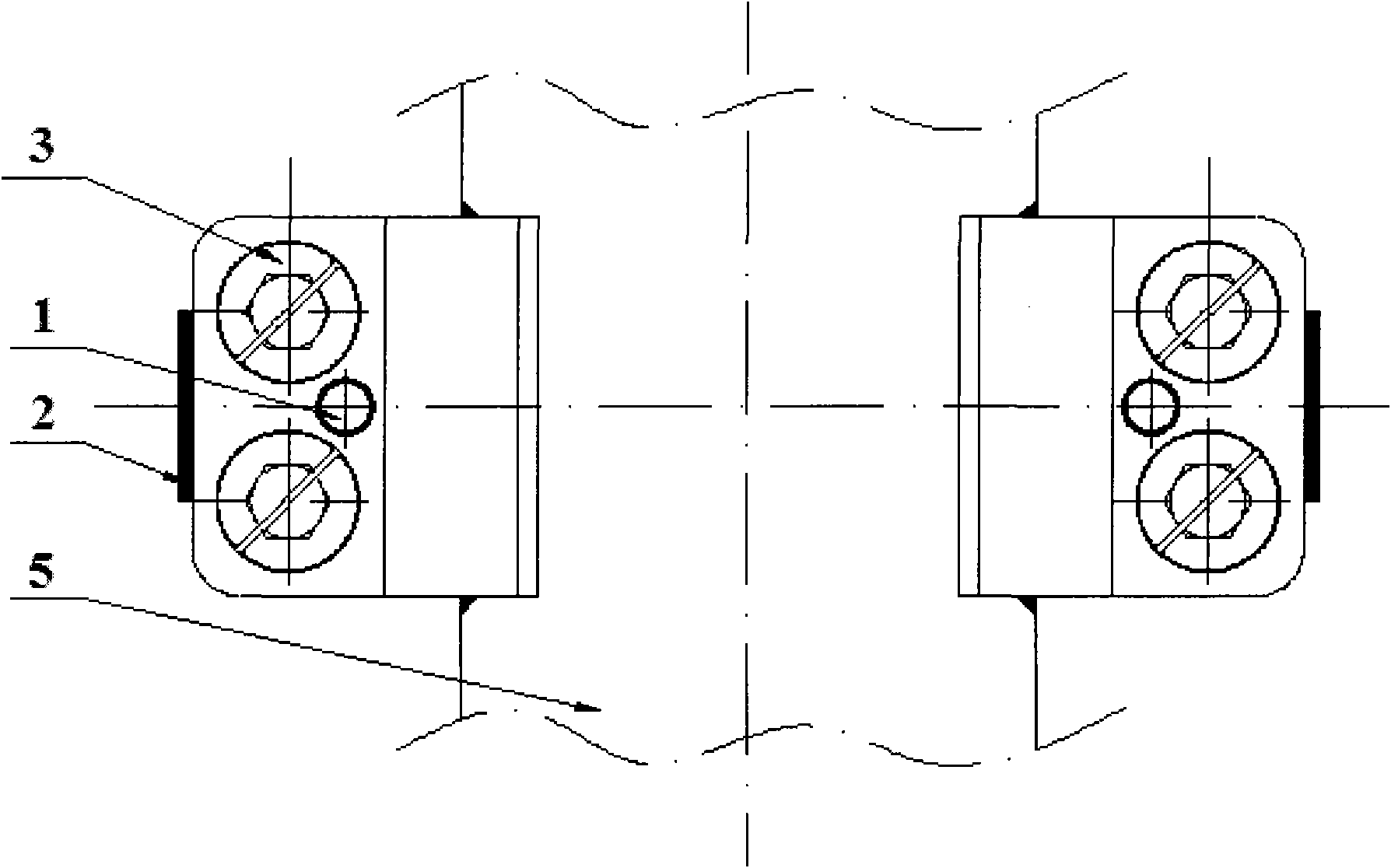

[0020] Such as figure 1 and figure 2 As shown, the support and positioning structure of the irradiation supervision tube is composed of eight sheath tubes 5, and each sheath tube has six layers of support brackets 4, which are positioned by positioning pins 1 and installed on the reactor pressure vessel hanging basket cylinder through bolts 3. , fixed on the outer wall 6 of the spider plant through the welds 2 on both sides of the support bracket.

[0021] The supporting positioning structure of the irradiation supervision tube is divided into two groups and fixed symmetrically on the outer wall of the hanging basket. After several operating cycles of irradiation, the dismantling of the supporting and positioning structure can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com