A terminal fitting and a crimping method

A terminal joint and terminal connection technology, which is applied in the field of terminal joints and its connection, can solve problems such as hindering the insertion of retainers, and achieve the effect of preventing widening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

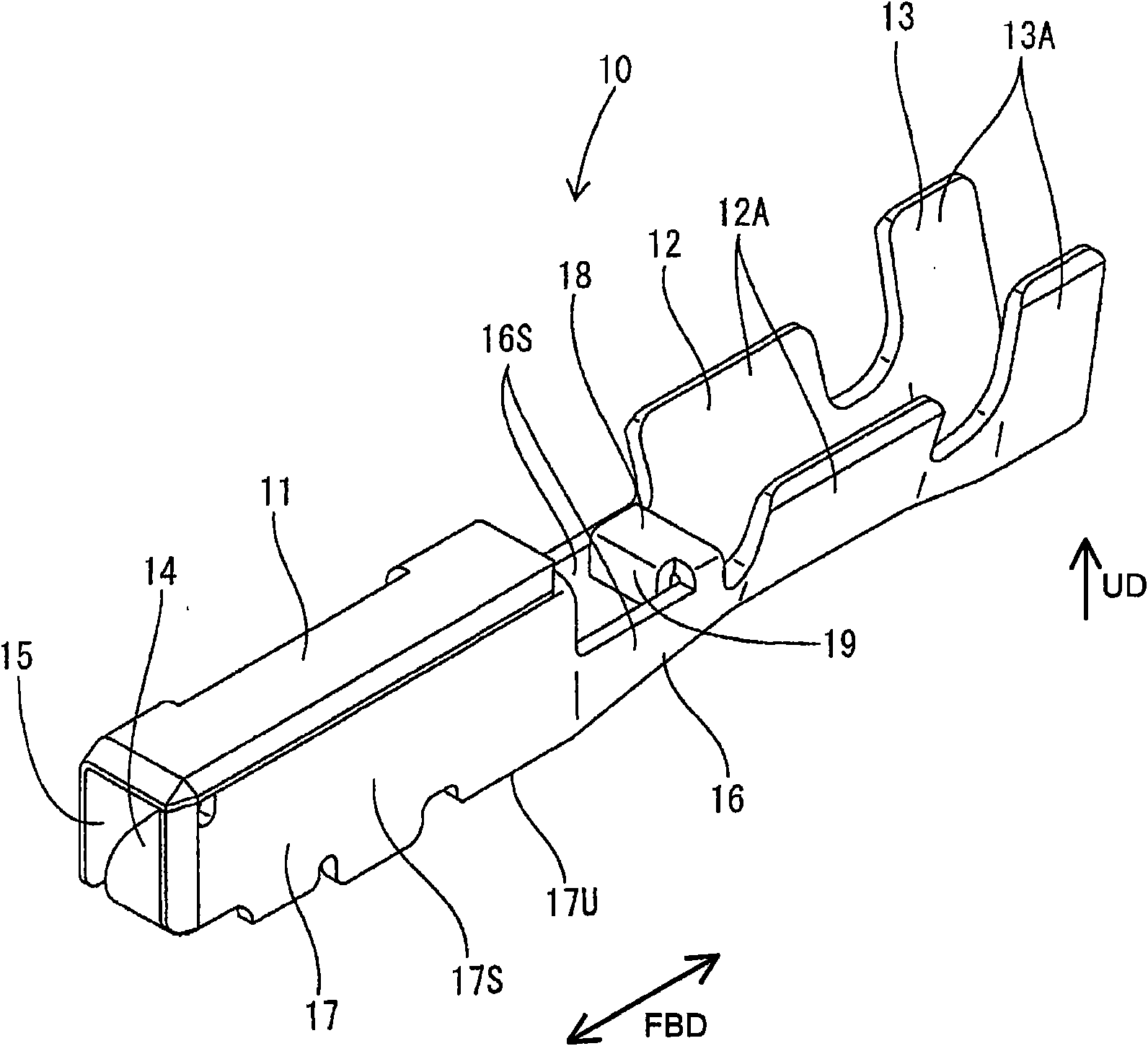

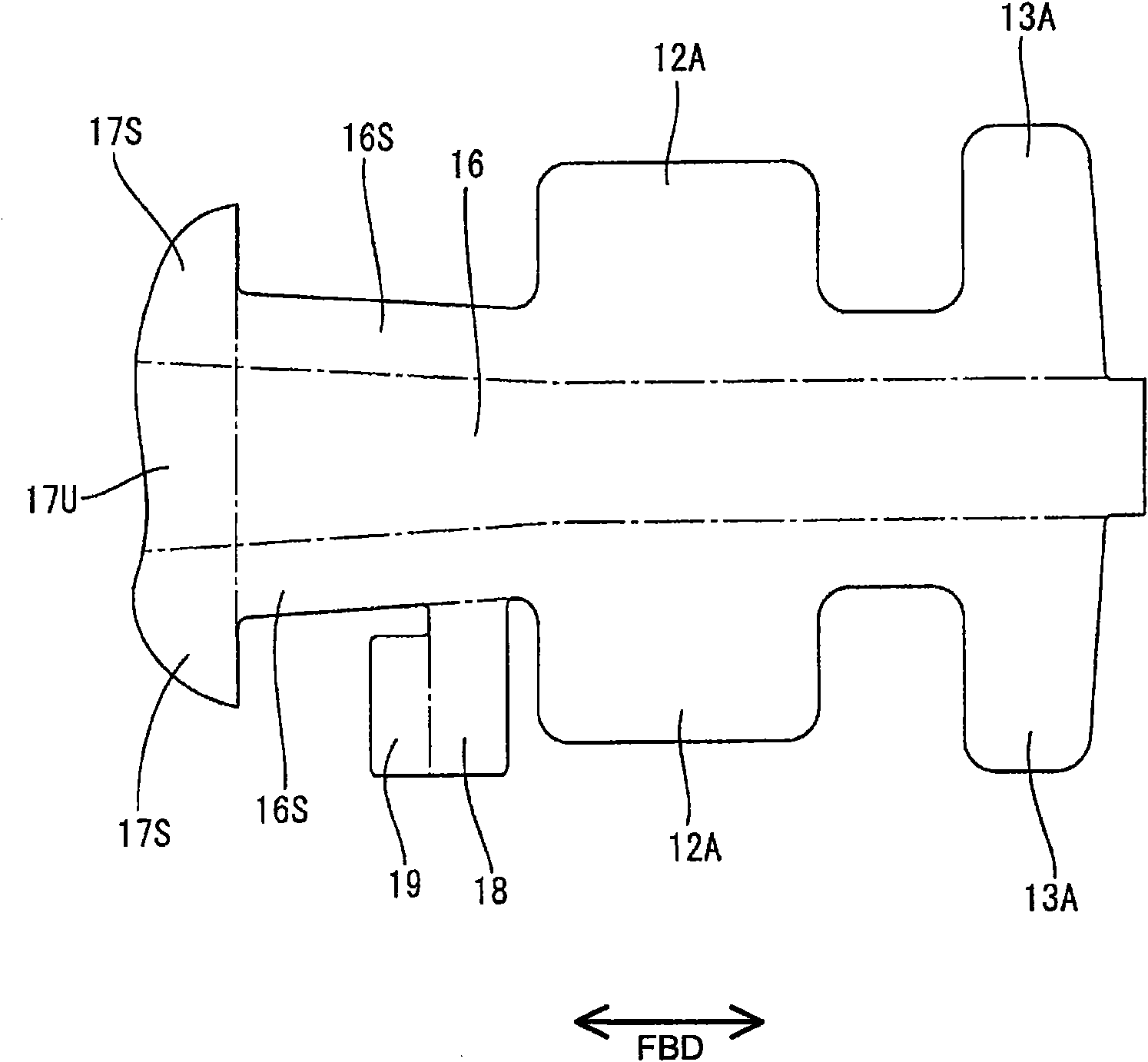

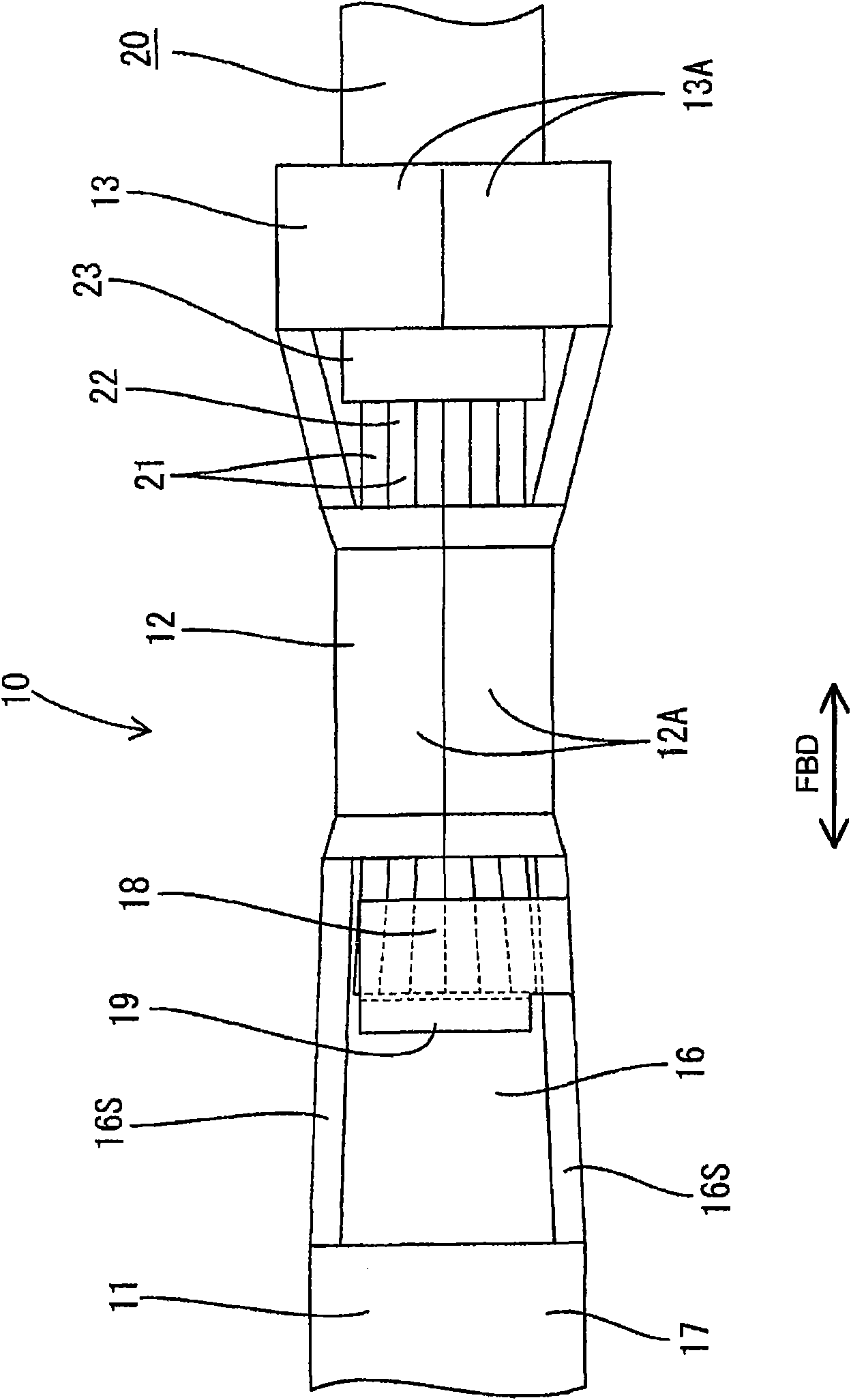

[0055] Refer below Figures 1 to 5A first preferred embodiment of the present invention is described. In the first embodiment, the present invention is applied to the female terminal fitting 10 . By stamping or stamping or cutting a substantially flat conductive (preferably metallic) sheet into a specific (predetermined or predeterminable) shape (in particular using a press-forming machine) and bending the cut or punched conductive (metallic) sheet , folding and / or embossing to form the terminal fitting 10 of the first embodiment. The terminal fitting 10 includes a connecting portion 11 connected to a mating male terminal fitting (not shown), and preferably at least one wire barrel 12 and / or at least one insulating tube 13 sequentially formed behind the connecting portion 11 . In the description below, figure 1 The upper, lower, lower left (towards the side of the connecting portion 11) and upper right sides are called upper, lower, front and rear sides.

[0056] The conne...

no. 2 example

[0080] Refer below Figures 6 to 8 A second preferred embodiment is described. The wire harness of the second embodiment is such that the terminal fitting 120 is connected to the front end portion of the electric wire 110 ( Figure 6 The left end in ) is electrically connected. The electric wire 110 is composed of a conductor 111 (preferably formed by twisting a plurality of thin metal wires) as a core wire and an insulating coating 112 at least partially surrounding the conductor 111 . At the front end portion of the electric wire 110 , as a preparation for connection with the terminal fitting 120 , the insulating coating 112 is removed in advance, thereby exposing the front end portion of the conductor 111 . Copper, a material having a higher rigidity than copper such as aluminum, or a material having a lower electrical conductivity than copper such as aluminum is preferably used as the material of the conductor 111 .

[0081] The terminal fitting 120 is specifically a fe...

no. 3 example

[0091] Refer below Figures 9 to 11 A third preferred embodiment of the present invention is described. The wire harness of the third embodiment differs from the second embodiment in the configuration of the terminal fitting 140 . Since other configurations are similar or identical to those in the second embodiment, similar or identical configurations are denoted by the same reference numerals, and their structures, functions, and effects will not be described again.

[0092] Similar to the second embodiment, the terminal fitting 140 of the third embodiment has a coupling portion 142 formed between the connecting portion 141 and the wire crimping portion 145 and is formed with one or more, preferably a pair of laterally symmetrical restricting portions 152 and a pair of (preferably also substantially laterally symmetrical) reinforcements 151 . One or more, preferably a pair of horizontal extensions 146 extending inwardly substantially parallel to the bottom plate 143 are for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com