Micronomicin sulfate eye drop and preparation method thereof

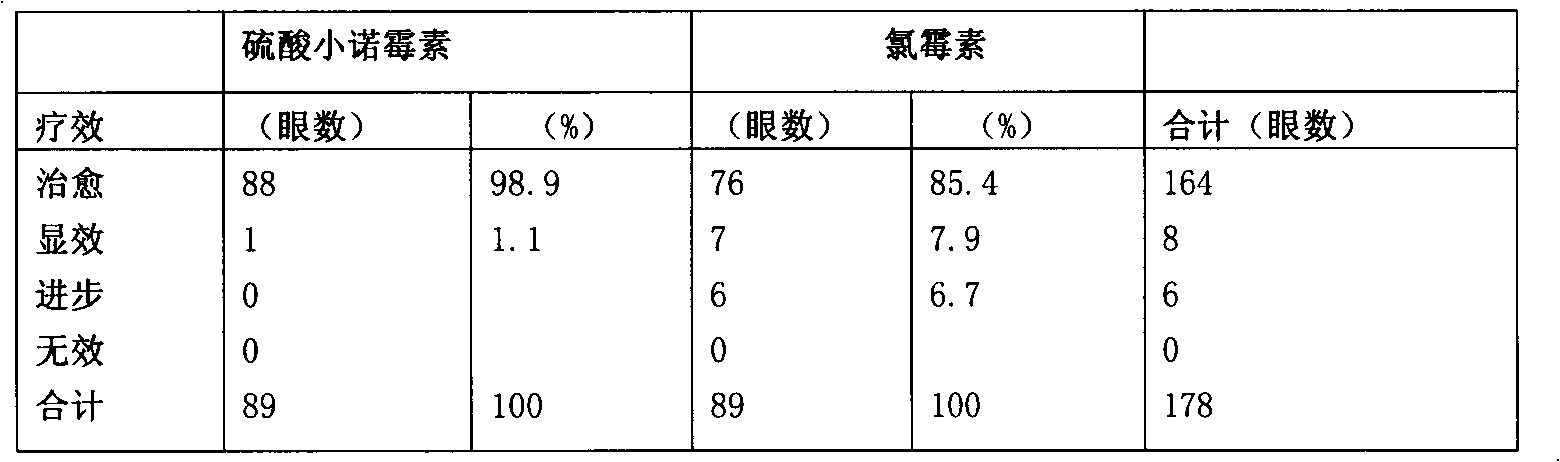

A technology of micronomycin and eye drops, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of low cure rate and poor treatment effect, etc. Achieve high cure rate, low toxic and side effects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The eye drops of this embodiment contain:

[0045] 3,000,000 units of micropromycin sulfate,

[0046] 8.0 grams of sodium chloride,

[0047] Sodium metabisulfite 2.0 grams,

[0048] 5.5 grams of hydroxypropyl cellulose with a concentration of 0.75% by weight,

[0049] 1000ml water for injection.

[0050] The preparation method is as follows: add 5.5 grams of hydroxypropyl cellulose aqueous solution with a concentration of 0.75% by weight to a container containing 400 ml of water for injection, stir and mix evenly, then add 8.0 grams of sodium chloride and 2.0 grams of sodium metabisulfite , After fully stirring and dissolving, add 3,000,000 units of micromycin sulfate, after dissolving, stirring and dissolving, adjust the pH to 7.0 with 0.5mol sodium hydroxide solution, add 600ml of water for injection to 1000ml of water for injection, use 0.22um micropore Sterilize the filter membrane.

Embodiment 2

[0052] The eye drops of this embodiment contain:

[0053] 3,000,000 units of micropromycin sulfate,

[0054] 8.0 grams of sodium chloride,

[0055] Sodium metabisulfite 2.0 g

[0056] 1000ml water for injection.

[0057] The preparation method is as follows: add 8.0 grams of sodium chloride and 2.0 grams of sodium metabisulfite to a 400ml water for injection container, fully stir to dissolve, add 3,000,000 units of micromycin sulfate, fully stir to dissolve, use 0.5mol Adjust the pH to 7.0 with sodium hydroxide aqueous solution, add 600ml of water for injection to 1000ml of water for injection, sterilize with 0.22μm microporous membrane.

Embodiment 3

[0059] The process and equipment of this embodiment are basically the same as in embodiment 1, except that the aqueous solution containing 2,000,000 units of micronomycin sulfate, 5.3 grams of sodium chloride, 1.3 grams of sodium metabisulfite, and a concentration of 0.03% by weight of hydroxypropyl cellulose 8 grams, 600 milliliters of water for injection.

[0060] The preparation method is as follows: adding 8 grams of an aqueous solution of hydroxypropyl cellulose with a concentration of 0.03% by weight to 240 milliliters of water for injection, adding the above amounts of sodium chloride, sodium metabisulfite and micronomycin sulfate, Adjust the pH to 6.0 with 0.3 mol sodium hydroxide aqueous solution, add 360 ml of water for injection, and sterilize with a 0.22 μm microporous membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com