Bloom continuous casting dynamic soft reduction process for high-quality tire cord steel

A light reduction, cord steel technology, applied in the field of metallurgical continuous casting, can solve the problems of differences in high temperature mechanical properties and solidification characteristics, different reduction efficiency and reduction amount, different alloy elements and contents, etc., to meet the technical requirements. Quality requirements, reducing center segregation, improving the effect of center porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Adopt technology of the present invention to control high-quality cord steel continuous casting bloom quality, bloom section size is 280mm * 325mm, and the main chemical composition (%) of pouring heat is as shown in the following table:

[0027] C

Si

Mn

P

S

0.72

0.22

0.54

0.008

0.007

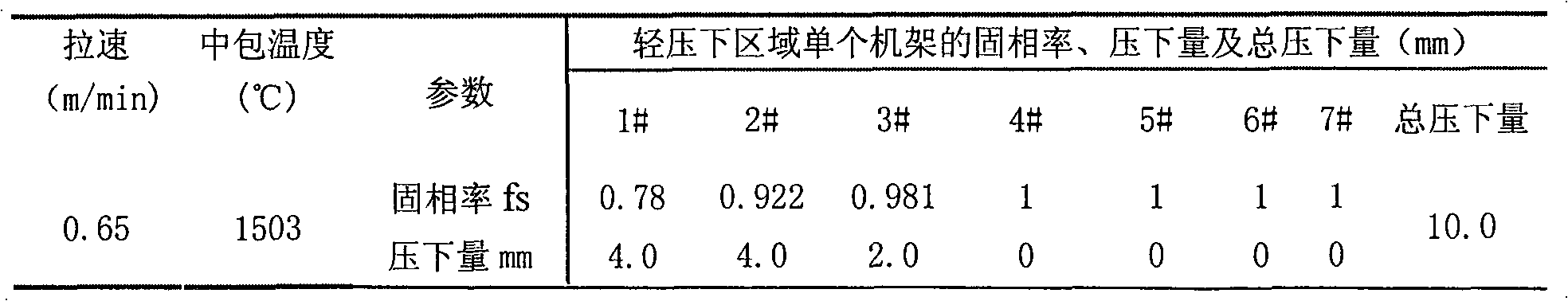

[0028] The main process parameters of pouring heat continuous casting are shown in the table below:

[0029]

Embodiment 2

[0030] Embodiment 2: Adopt technology of the present invention to control high-quality cord steel continuous casting bloom quality, bloom section size is 280mm * 325mm, and the main chemical composition (%) of pouring heat is as shown in the following table:

[0031] C

Si

Mn

P

S

0.73

0.22

0.55

0.007

0.007

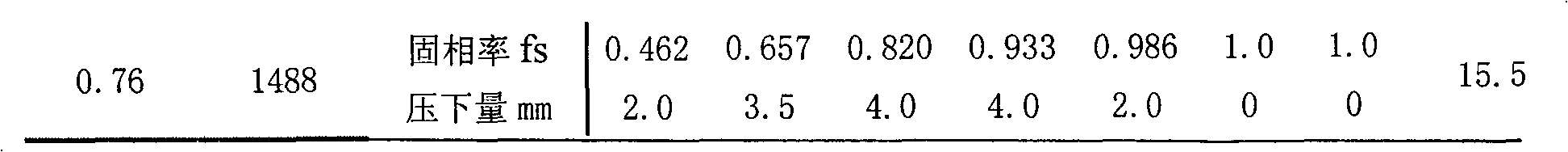

[0032] The main process parameters of pouring heat continuous casting are shown in the table below:

[0033]

[0034]

Embodiment 3

[0035]Embodiment 3: adopt the process of the present invention to control the quality of the high-quality cord steel continuous casting bloom, the bloom cross-sectional size is 280mm * 325mm, the main chemical composition (%) of the pouring heat is shown in the following table:

[0036] C

Si

Mn

P

S

0.72

0.23

0.54

0.006

0.007

[0037] The main process parameters of pouring heat continuous casting are shown in the table below:

[0038]

[0039] The process of the present invention reduces and eliminates defects such as slab center segregation, center looseness, and center shrinkage cavity through continuous casting slab dynamic light reduction, and the carbon segregation index of the slab center is controlled at 0.96-1.05, with an average of 1.03; the process can also Significantly improve the central porosity and central shrinkage cavity of the cord steel casting slab, the central porosity of the casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com