Preparation method of aluminium-lithium intermediate alloys

A master alloy, aluminum-lithium technology, applied in the field of preparation of aluminum-lithium alloy, can solve problems such as difficult preparation of aluminum-lithium master alloy, complicated operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] a) taking lithium oxide as a raw material, and preparing lithium metal liquid by molten salt electrolysis;

[0045] b) melting pure aluminum ingots to prepare molten aluminum;

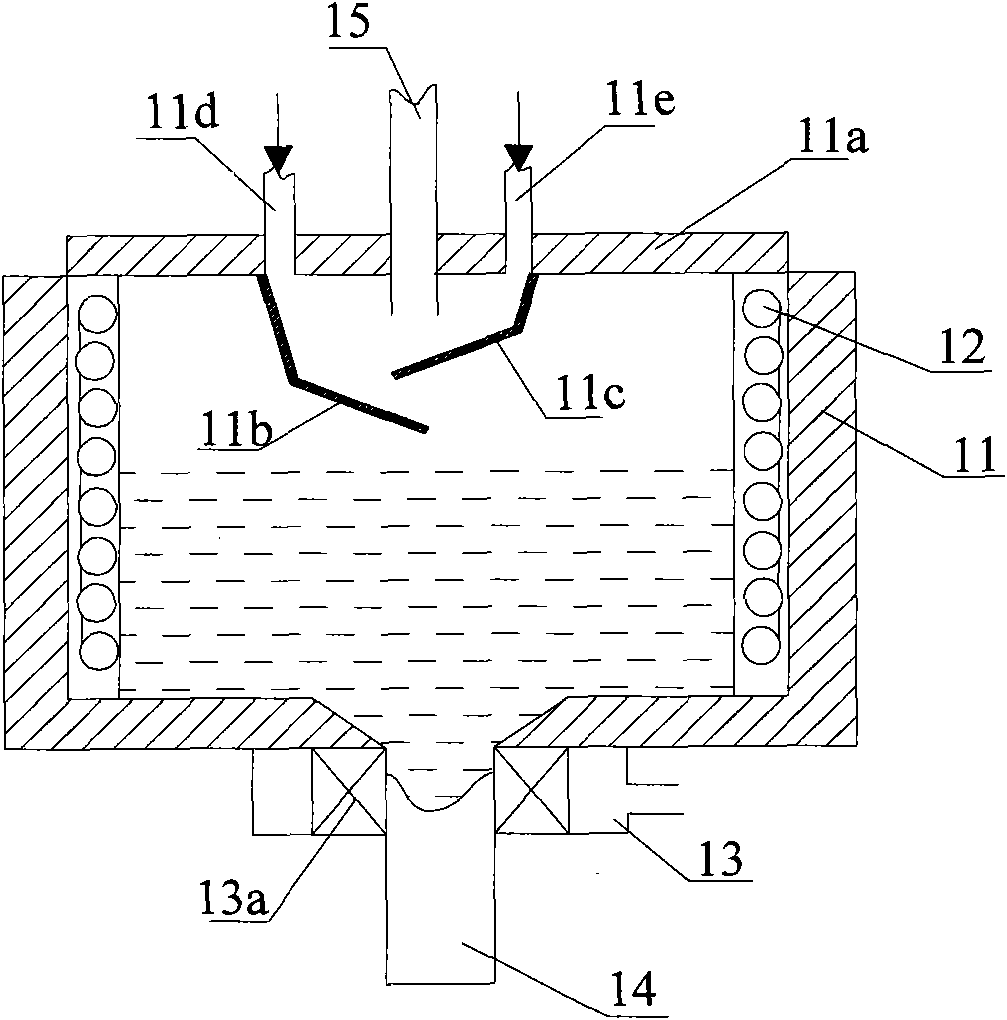

[0046] c) transporting the molten lithium metal to the melting furnace through the first feeding port 11d, and simultaneously transporting the molten aluminum metal to the melting furnace through the second feeding port 11e, the molten lithium metal and the molten aluminum passing through the first launder 11b respectively and the second launder 11e flow down to the lower part of the smelting furnace, and are well mixed to form a mixed metal liquid in the process of flowing. The weight ratio of aluminum and lithium in the mixed metal liquid is aluminum: lithium is 85:15, and the smelting furnace is fed into Argon as a shielding gas;

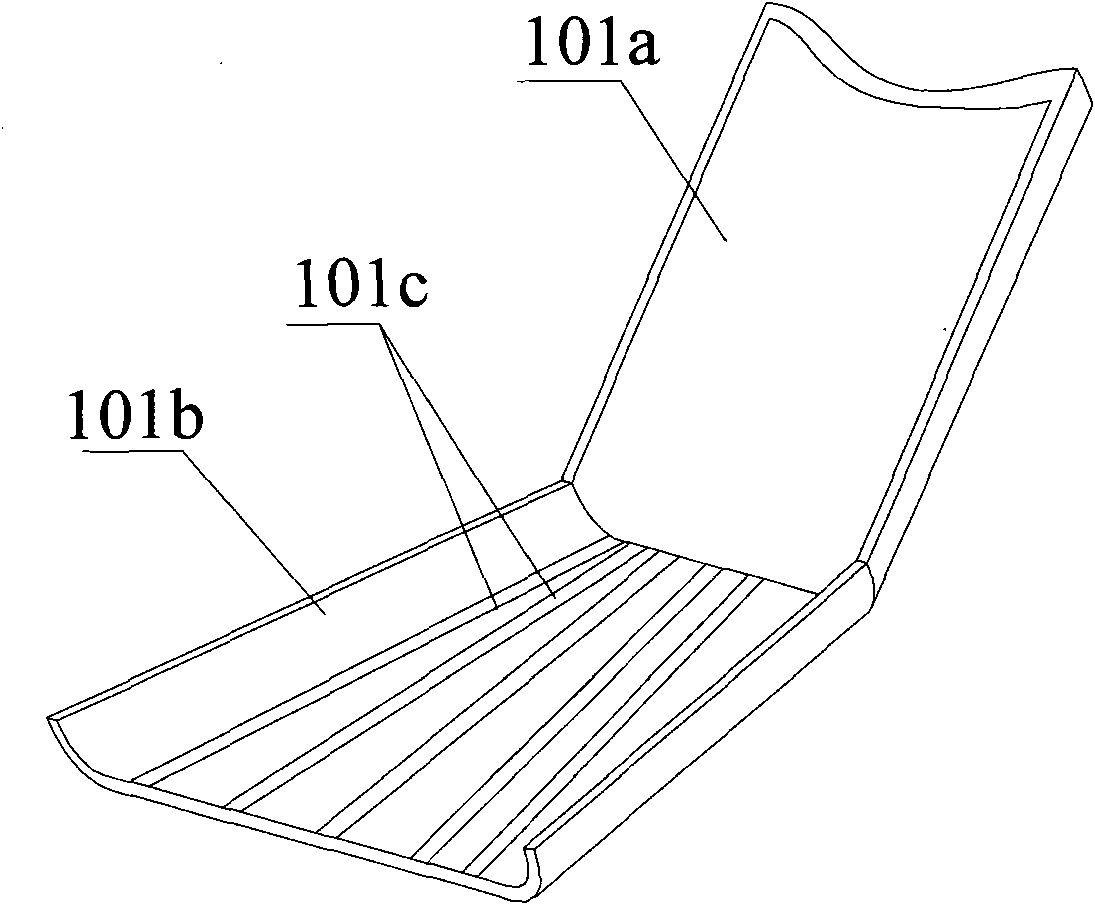

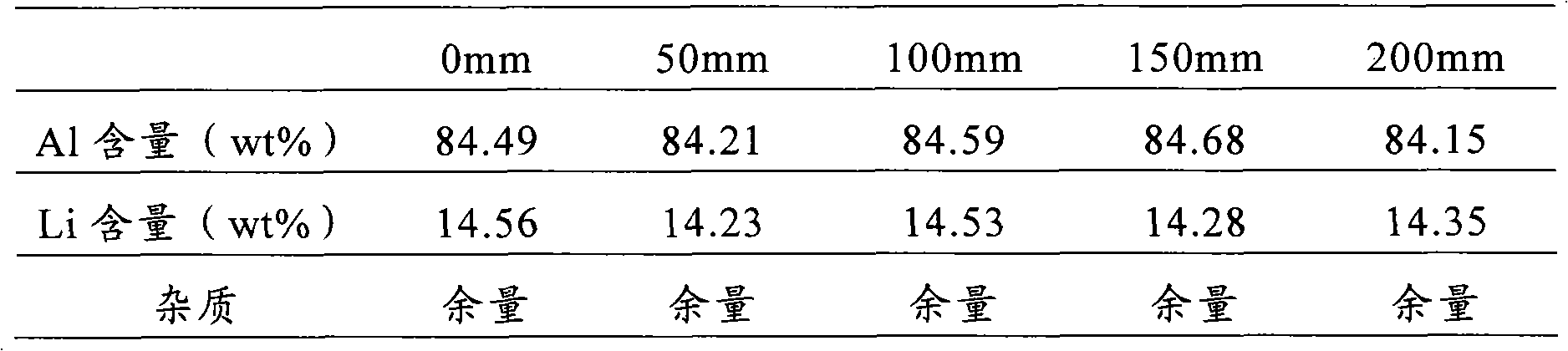

[0047] d) The temperature in the smelting furnace is set to 750°C. After the mixed metal liquid falls into the crystallizer, the cooler of the crystallizer is tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com