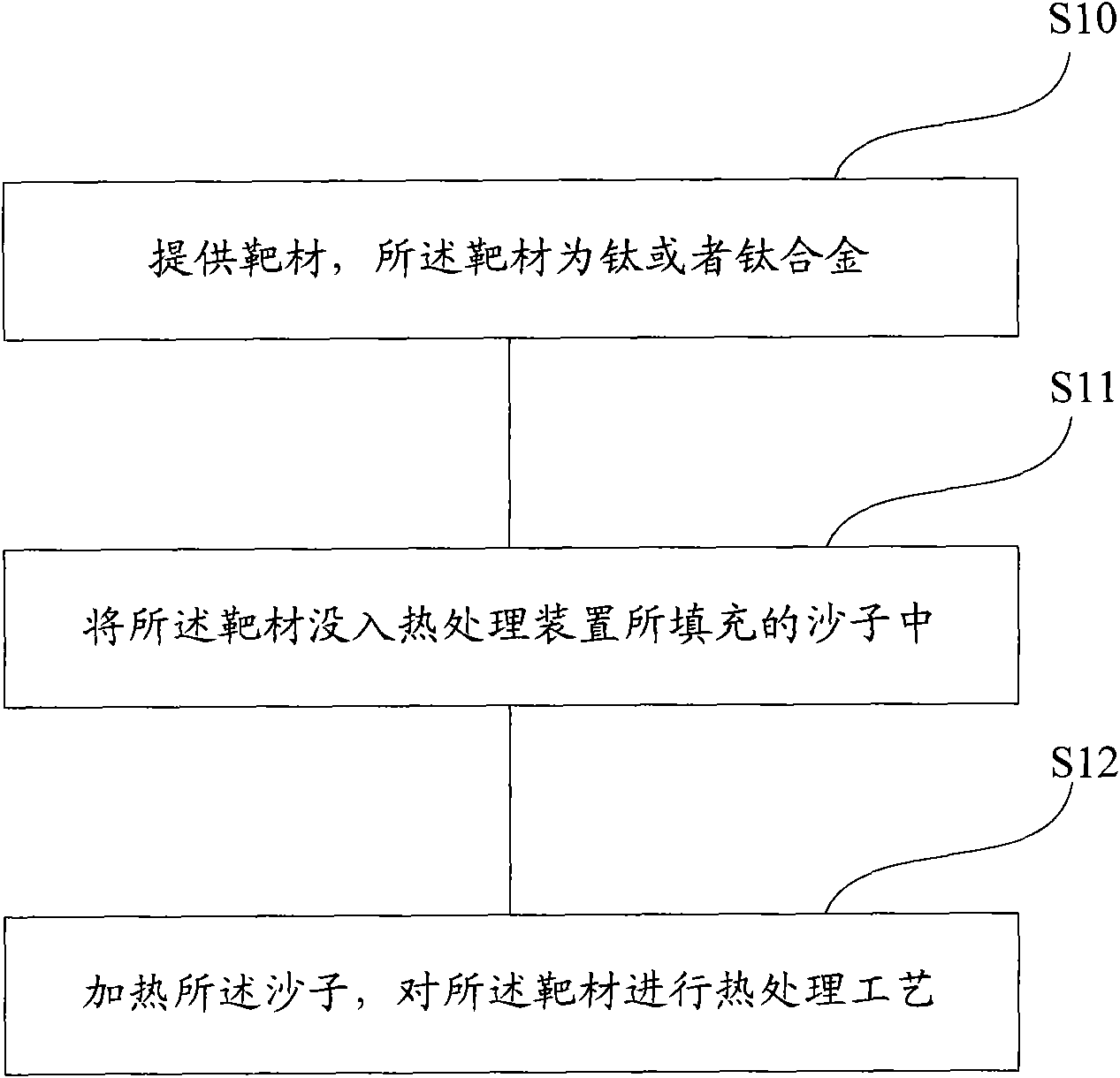

Heat treatment method of target material

A heat treatment method and technology of a heat treatment device, which are applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as uneven structure and uneven heating of targets, and achieve uniform structure and meet the requirements of sputtering. Requirements, the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0048] The following takes 4N5 or 5N titanium target as an example to illustrate the process steps and results of heat treatment in the target heat treatment method of the present invention:

[0049] (1) Provide titanium targets after plastic deformation process. The titanium target material through the plastic deformation process has a structure with a better grain size.

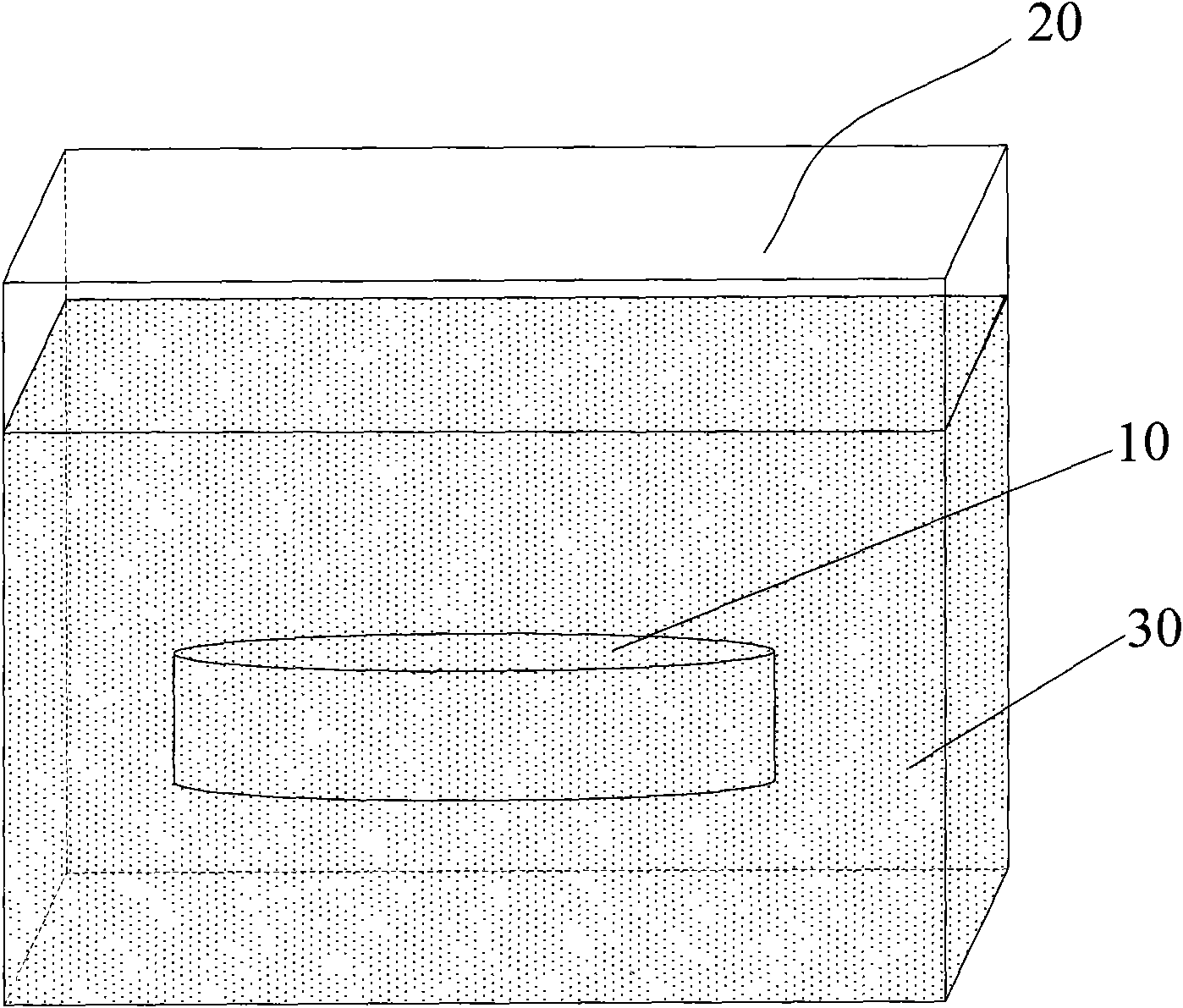

[0050] (2) Submerge the titanium target material into the sand filled in the heat treatment device, so that the periphery of the titanium target material is covered by sand. What described sand adopts is No. 45 silicon carbide (45#SiC).

[0051] (3) Heat the sand and heat-treat the target. Specifically include: the heating temperature is 550° C., and the temperature is kept at this temperature for 5.5 hours.

[0052] Through the above steps, a target that meets the sputtering requirements is finally obtained.

[0053] The target heat treatment method provided by the present invention adopts the sand bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com