Curve disk-type hydraulic pressure sensor for built-in modulation circuit

A water pressure sensor and conditioning circuit technology, which is applied in fluid pressure measurement using piezoelectric devices, etc., can solve the problems that it is not easy to reduce the output impedance, the sensitivity of low-frequency response is difficult to improve, and the signal conditioning circuit has high requirements for impedance matching and frequency response. , to achieve the effects of suppressing adverse effects, improving stability and reliability, and improving low-frequency sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

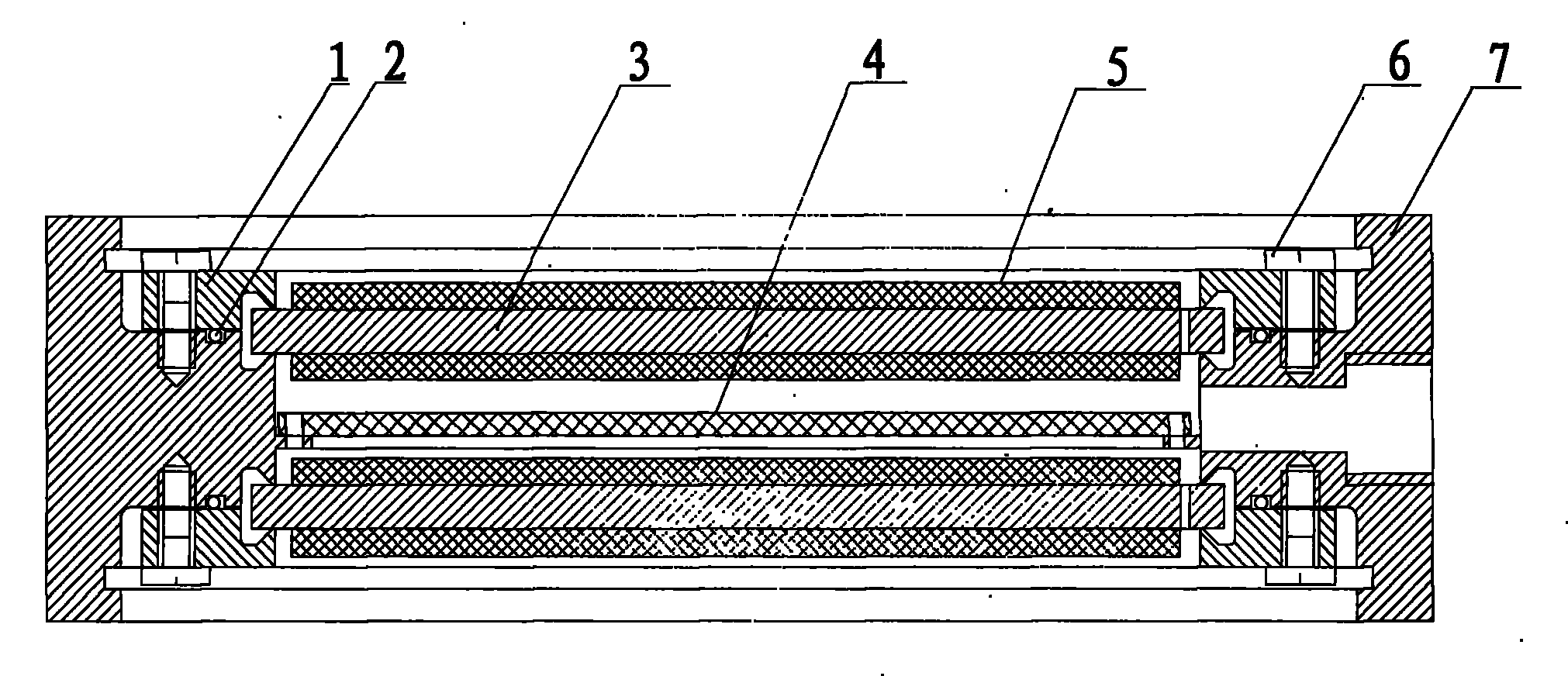

[0009] The main structure is as figure 1 As shown, the present invention is mainly composed of a pressure ring 1, an O-ring 2, a support piece 3, a conditioning circuit 4, a piezoelectric ceramic disc 5, a screw 6, a support base 7, and the like.

[0010] The four piezoelectric ceramic discs 5 are circular sheets with a relatively large diameter and thickness, which are respectively bonded to the front and back sides of the two support plates 3 with conductive adhesive, so that the polar plates on one side of the piezoelectric discs with the same polarity pass through. The support piece 3 made of conductive metal is connected, and the pole plate on the other side is connected by a wire to form a parallel structure on the electrical connection, forming two triple-chip sensitive elements; the support base 7 is a cylindrical metal hollow cavity, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com