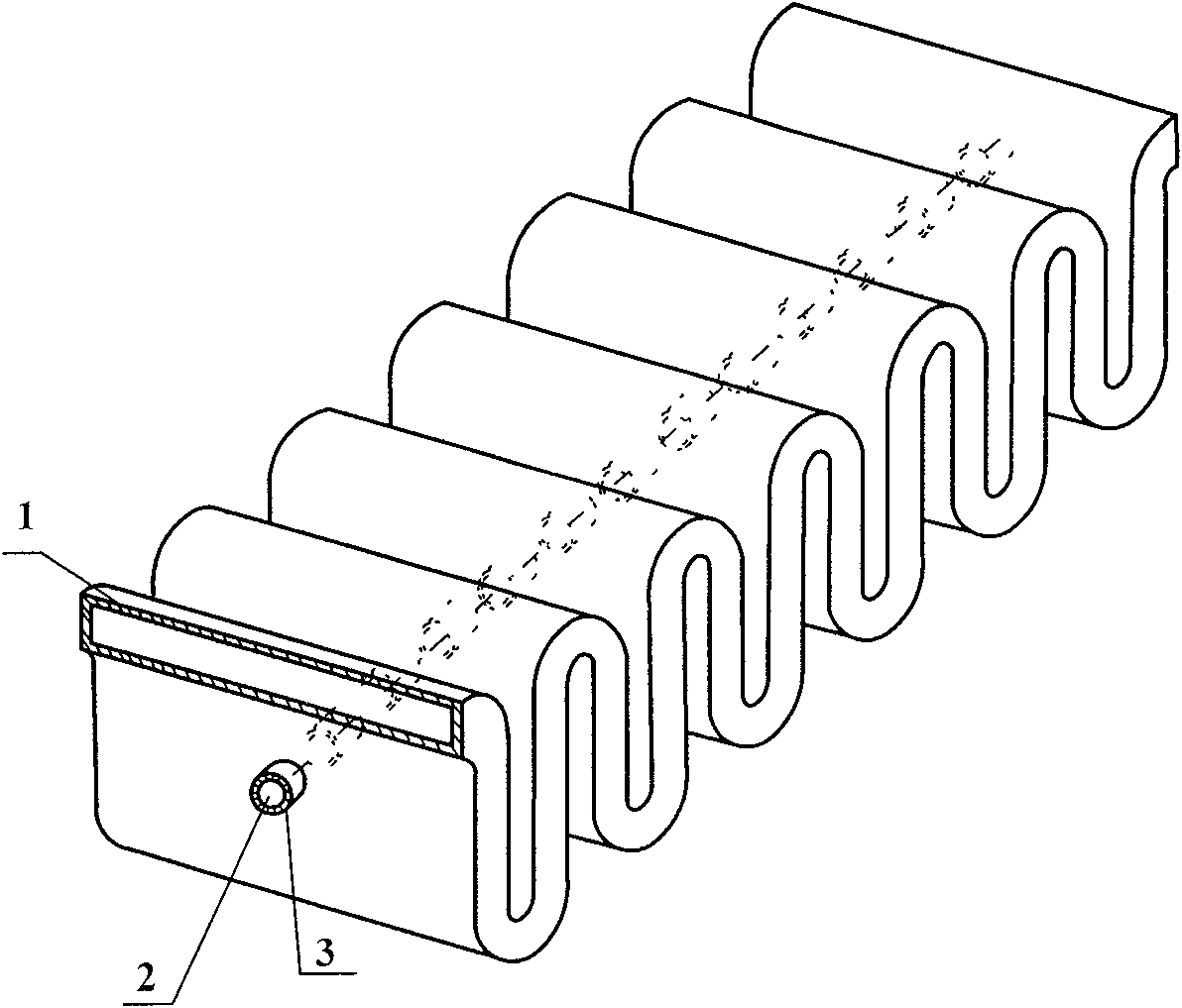

Ridge loading zigzag waveguide slow wave line

A meandering waveguide and slow wave line technology, applied in the field of traveling wave tube amplifier devices, can solve the problems such as the limitation of the gain and efficiency of the traveling wave tube, the low coupling impedance of the meandering waveguide slow wave structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

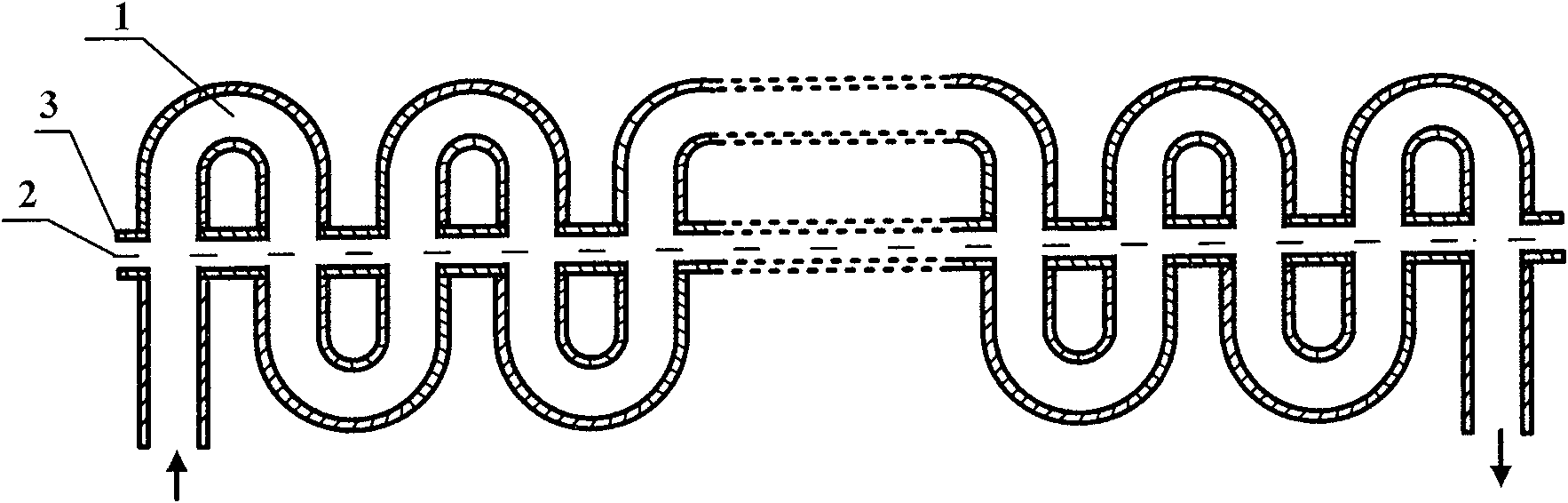

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

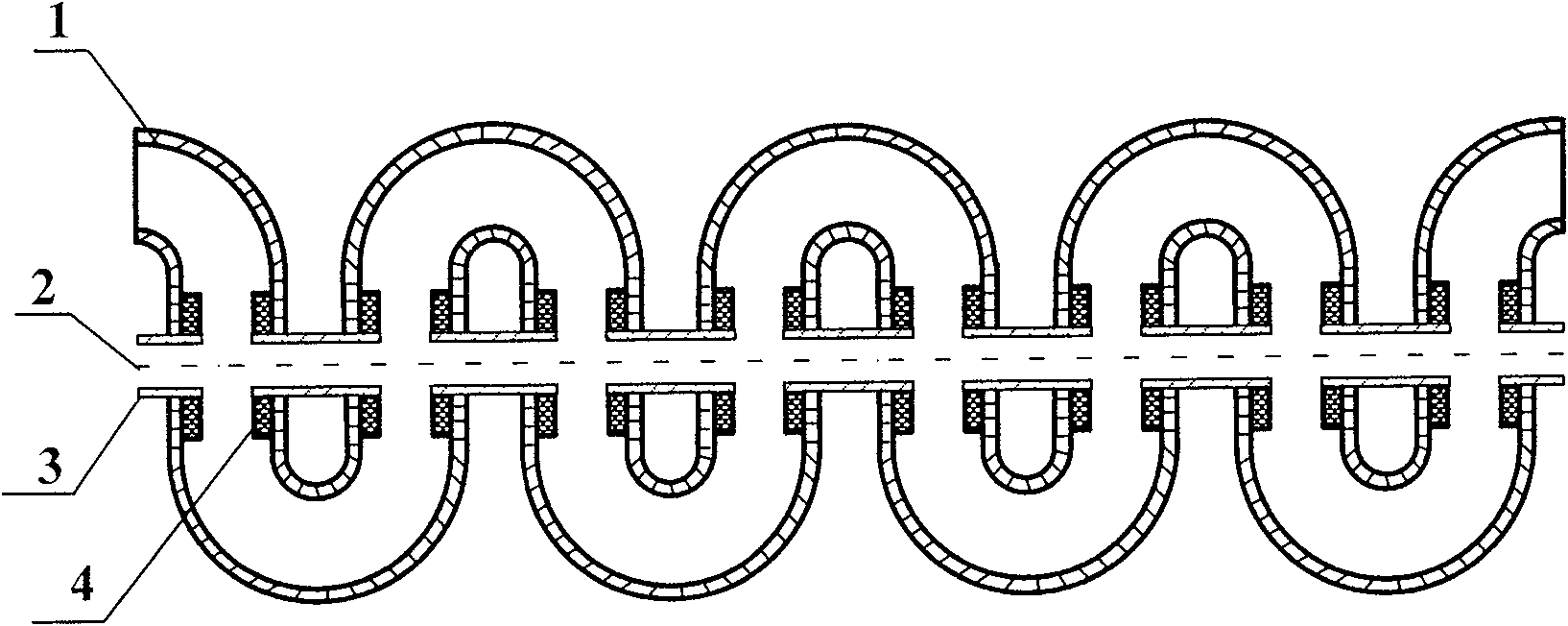

[0021] Such as Figure 4 and Figure 5 , in the 8mm millimeter wave band, the structural dimensions of the specific scheme of the meandering double-ridge waveguide slow wave line are as follows (unit: mm): a=5, b=0.8, L=4.56, H=2.2, r 0 =0.5, w=5, d=0.25, h=2.2. Use three-dimensional electromagnetic simulation software to simulate the ridge-loaded meander waveguide slow-wave line provided by the present invention, obtain its dispersion characteristics and coupling impedance, and compare it with the meandering double-ridge slow-wave structure and ordinary meander waveguide slow-wave line. The simulation results are as follows Figure 6 and Figure 7 shown. Curve 5 and Curve 8 are the dispersion characteristic curve and coupling impedance curve of the ordinary meandering waveguide slow-wave structure respectively, Curve 6 and Curve 9 are the dispersion characteristic curve and coupling impedance curve of the meandering double-ridge waveg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com