Chip-type contact of electric connector for terminating cable

A technology for electrical connectors and contacts, applied in the direction of contact components, connections where permanent deformation works, etc., can solve the problems of deformation and damage of side walls, lack of support and protection, etc., and achieve the effect of reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

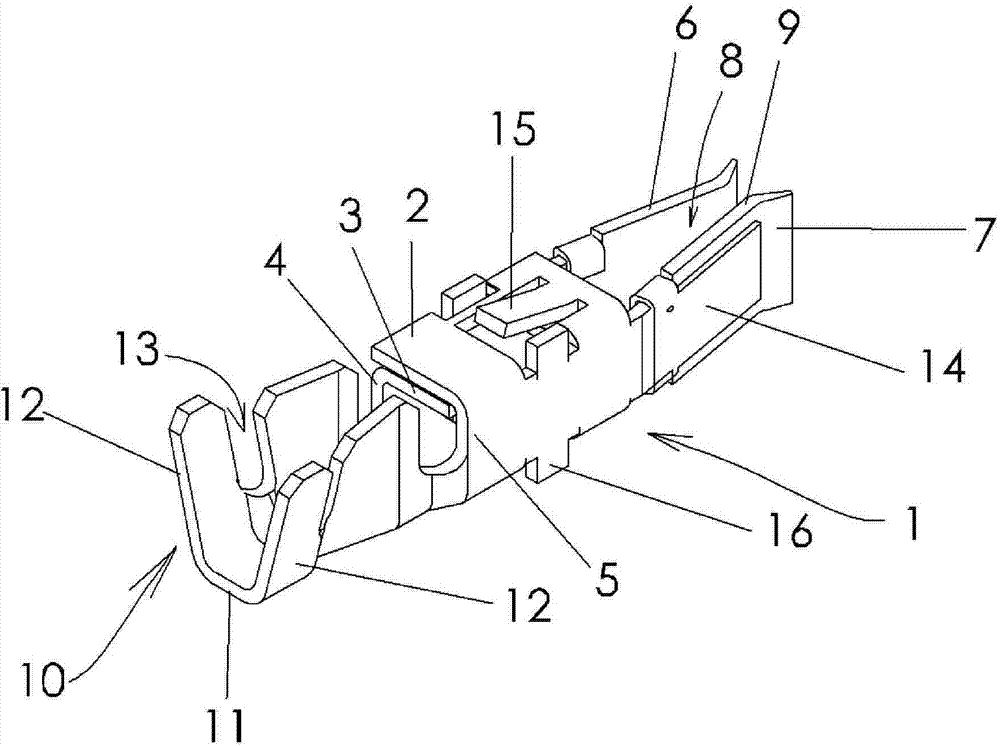

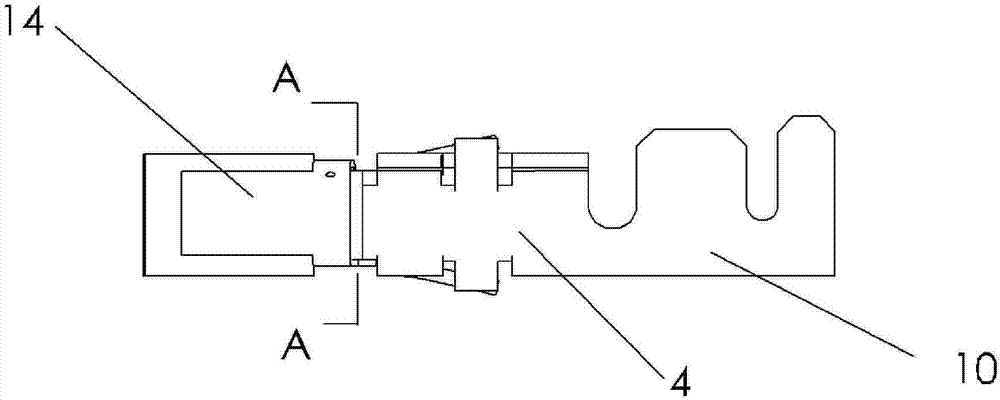

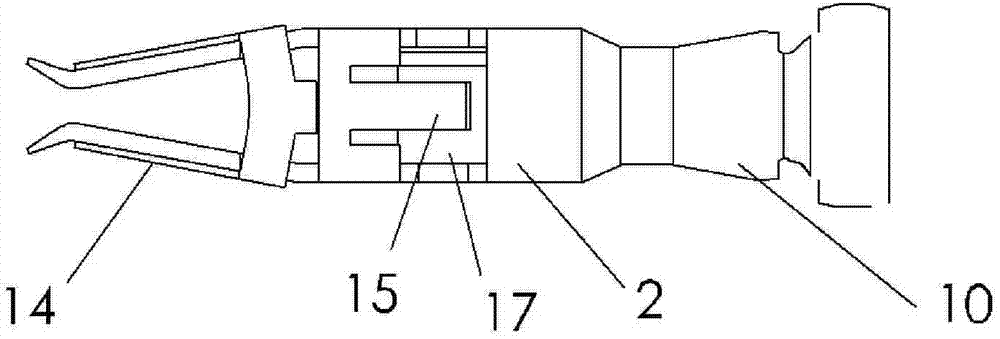

[0019] Such as Figure 1 to Figure 5 As shown, an embodiment of the sheet contact of the present invention, the main body of the contact is a receptacle contact formed by punching and bending a metal sheet, with a front plug-in terminal and a rear clamp structure 10 , and a sheath 14 is set on the plug-in end. The middle part of the contact piece is a rectangular hollow frame body 1 with a cross-section surrounded by surrounding wall panels. The top surface of the frame body 1 is formed by overlapping two layers of top wall panels 2 and 3. The side wall panels 4 and 5 respectively extend from the panels 2 and 3, and the bottom surface of the frame body 1 is a bottom wall panel 6 bridged between the two side wall panels, and the two layers of top wall panels 2 and 3 are close to the inside The edge of the top wall plate 3 leans against the opposite side wall plate 5, forming a reliable support protection between the opposite side wall plates, preventing the wire clip structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com