Dispergation device and dispergation method thereof

A technology of degumming and carrying devices, applied in chemical instruments and methods, dissolving, dissolving, etc., can solve the problems of high cost, poor degumming, pollution, etc., and achieve the effect of low assembly cost, simple structure, and improved degumming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

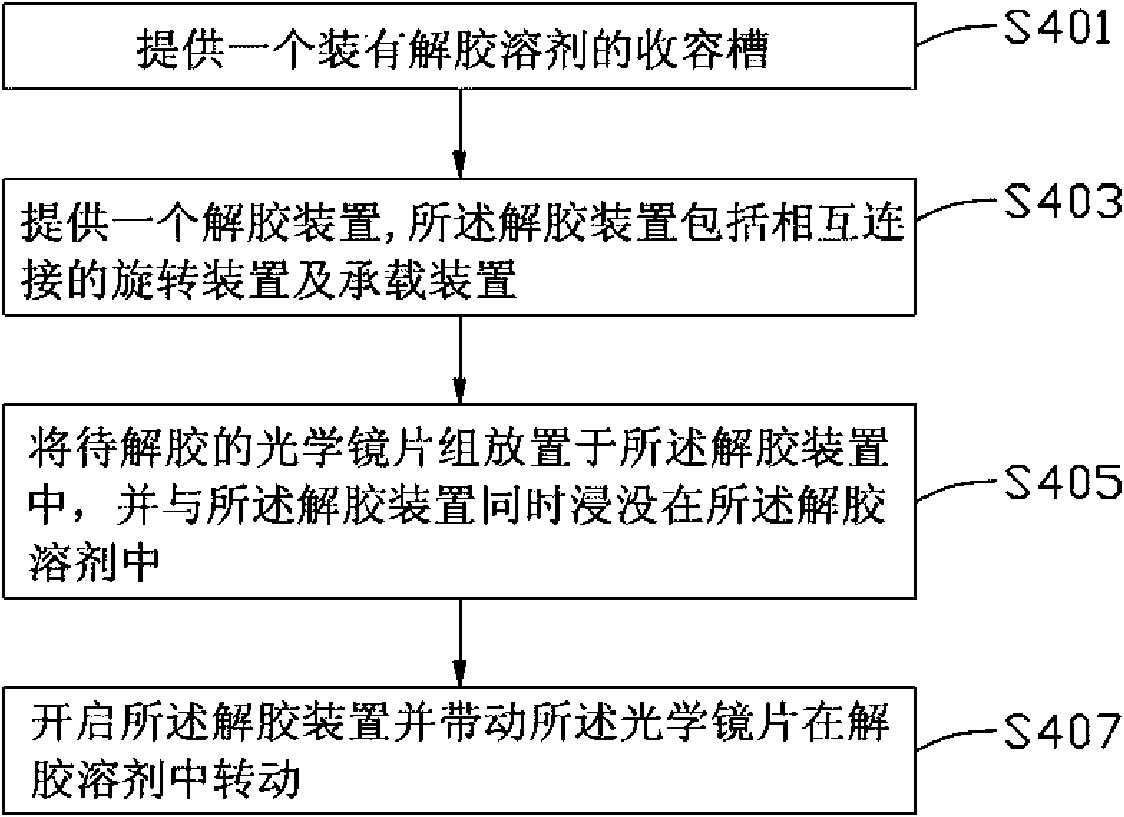

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

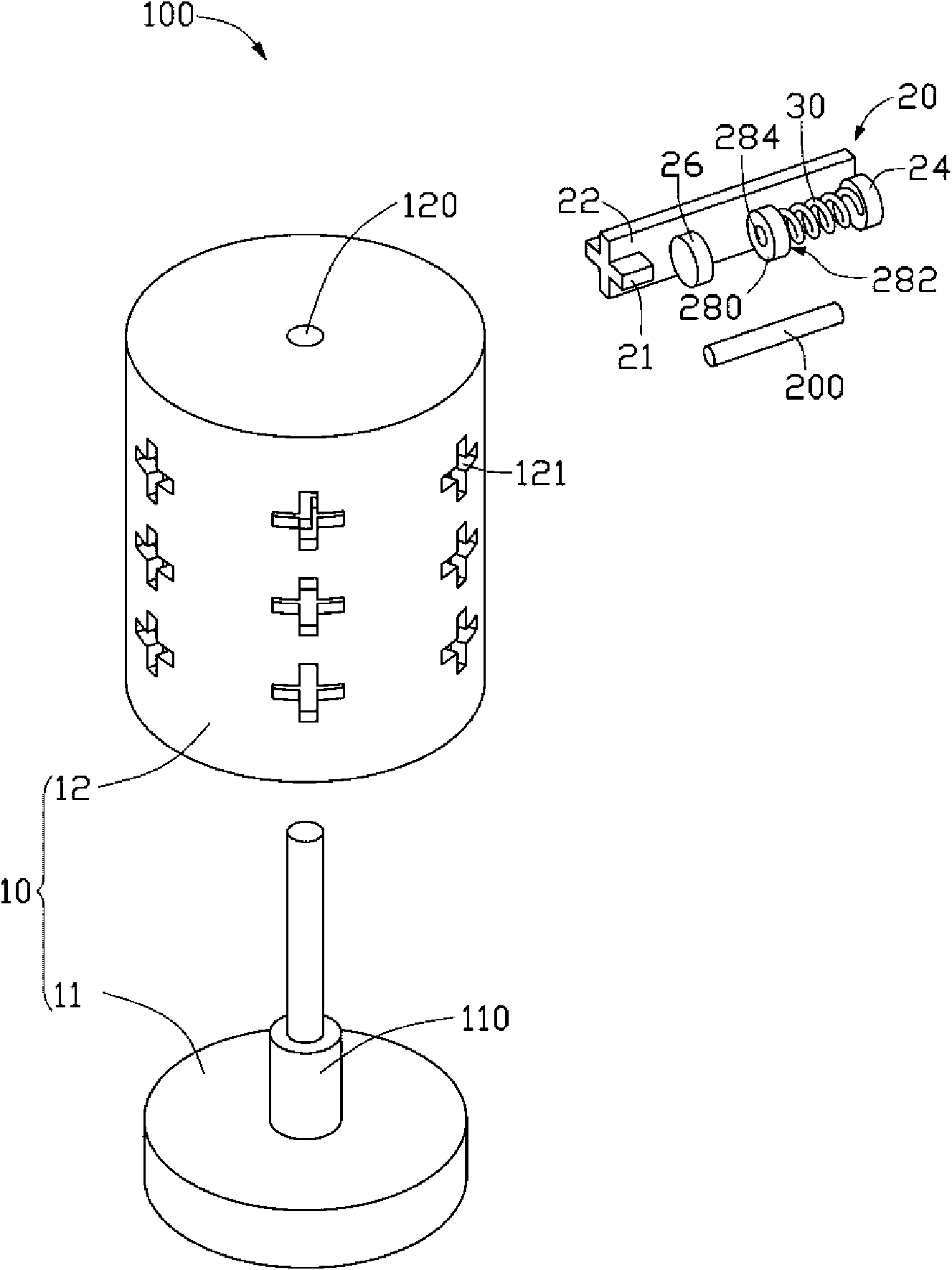

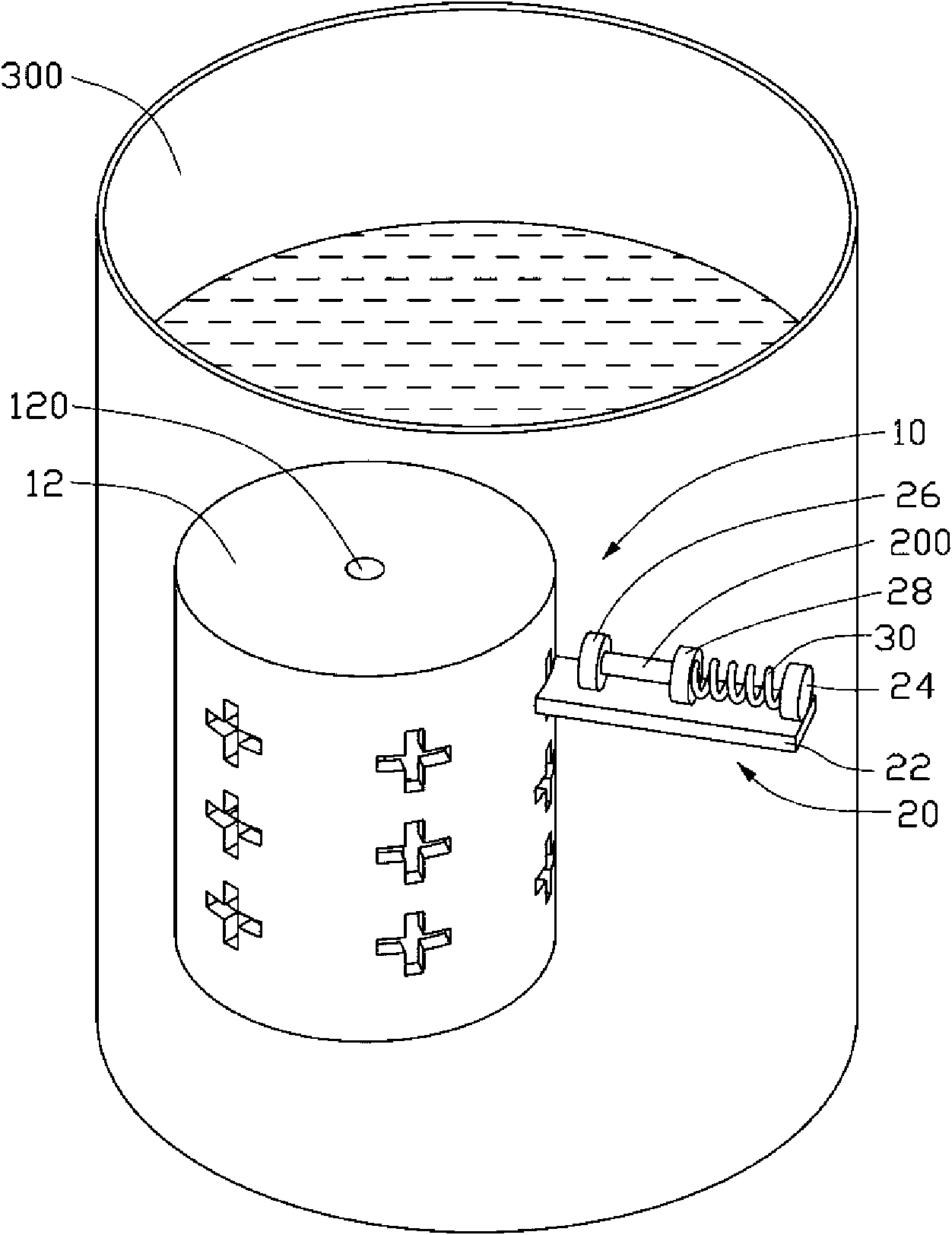

[0014] Please also refer to figure 1 and figure 2 , a degumming device 100 provided in an embodiment of the present invention is used for dissolving the bonding glue between the optical lens groups 200 by being placed in a degumming solvent. The degumming device 100 includes a rotating device 10 and a carrying device 20 . The carrying device 20 is used for carrying the optical lens set 200 . The carrying device 20 is fixed on the rotating device 10 so that the rotating device 10 can drive the carrying device 20 to rotate.

[0015] The peptizing solvent is an organic solvent or water. In this embodiment, the peptizing solvent is water.

[0016] The rotating device 10 includes a rotating shaft 11 and a rotating housing 12 . A rotating motor 110 is arranged on the rotating shaft 11 , and the rotating motor 110 can drive the rotating shaft 11 to rotate. The rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com