Full automatic numerical control connecting rod milling potential machine tool

A flat milling, fully automatic technology, applied in the field of CNC machine tools, can solve the problems of difficult plane machining by CNC lathes, high workpiece processing cost, slow processing speed, etc., to achieve the effect of fast processing speed, stable processing quality, and small processing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

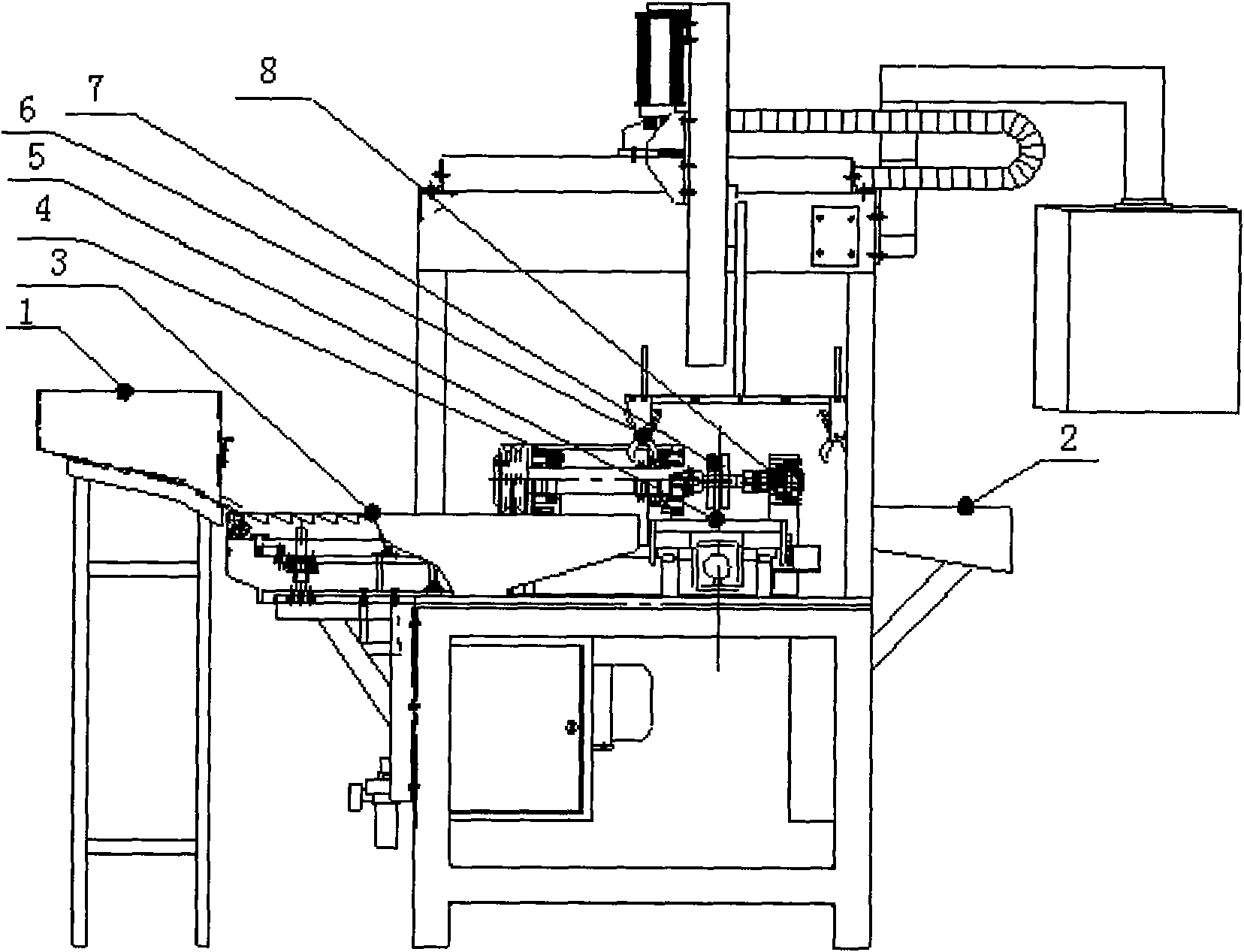

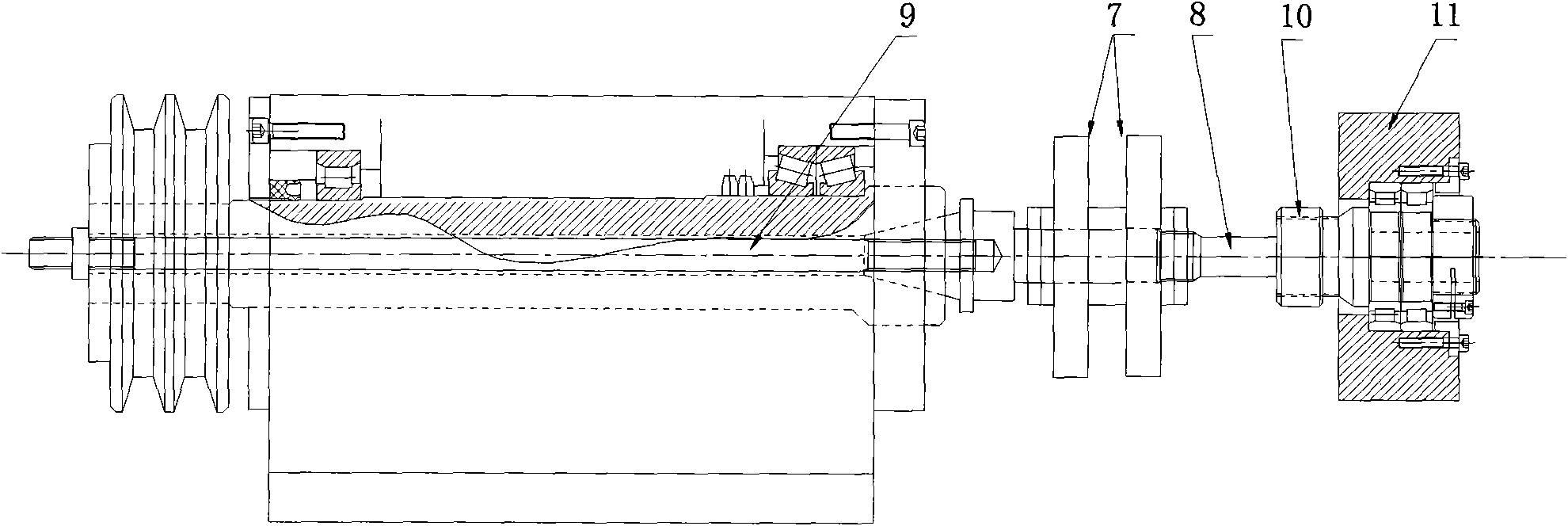

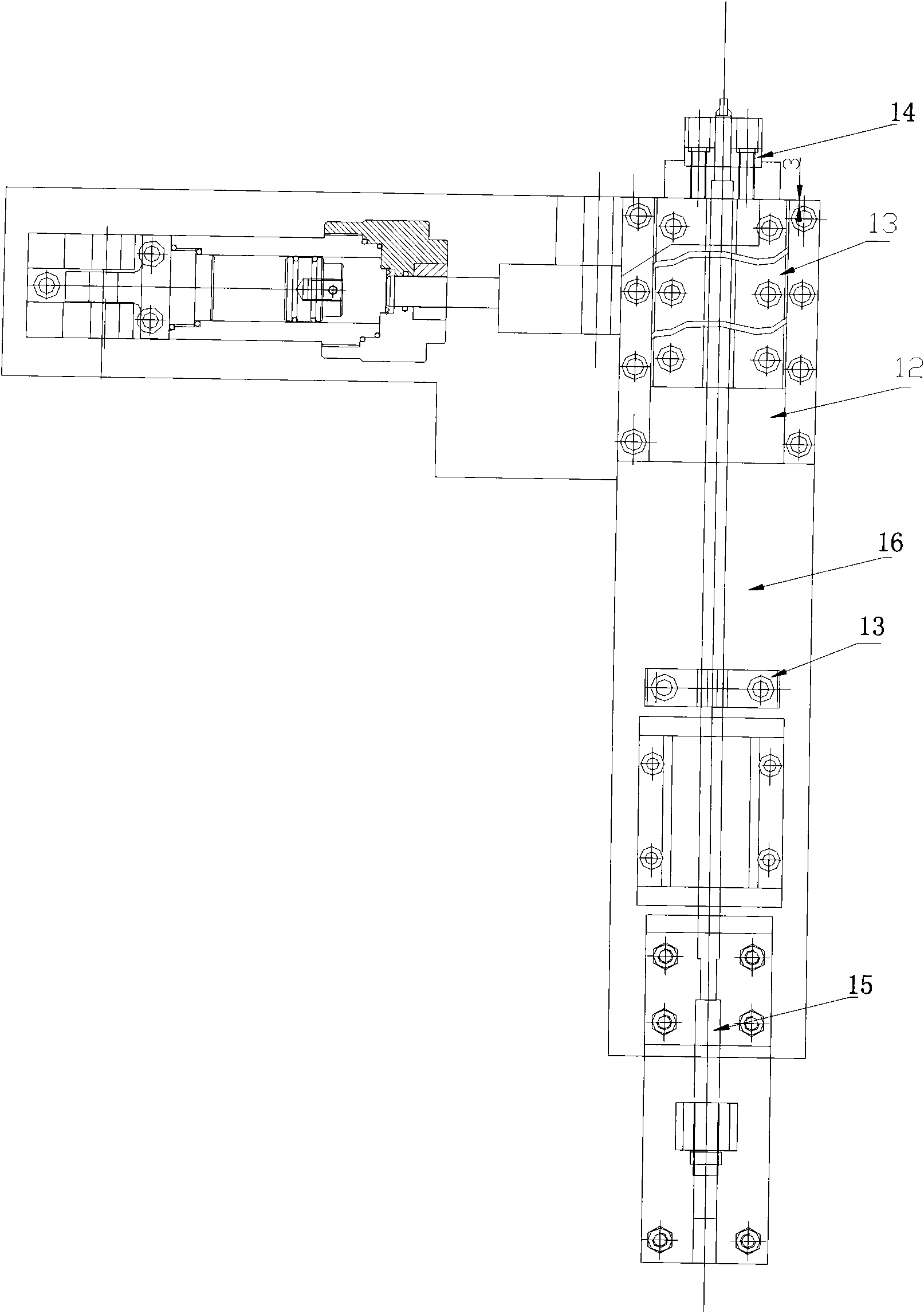

[0035] Such as Figure 1~5 As shown, the fully automatic CNC connecting rod milling and flattening machine tool includes an upper hopper 1, a lower hopper 2, a helical gear conveying mechanism 3, a spindle box 4, a workbench 5, a manipulator 6, positive and negative cutters 7, and a tool bar 8. The upper hopper 1 is connected to the helical-toothed conveying mechanism 3, and the helical-toothed conveying mechanism 3 is set on one side of the workbench 5, and the positive and negative cutters 7 are arranged above the workbench 5, and the positive and negative cutters 7 are installed on the cutter bar 8, one end of the knife rod 8 is tightened with a pull rod 9, and the other end is fixed on the tool holder 11 with a quick chuck 10, and the workpiece to be processed is placed in the upper hopper 1, and is sent by the helical-toothed conveying mechanism 3. Enter the workbench 5, the manipulator 6 automatically takes the workpiece to be processed and puts it into the processing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com