Special edge planer for steel band

A technology of edge planing machine and steel strip, applied in the direction of planer groove machine, planer/slotting machine, metal processing equipment, etc., can solve the problems of not meeting production needs, a large number of chamfering equipment and manpower, etc., to achieve a high degree of automation, saving Production cost, the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

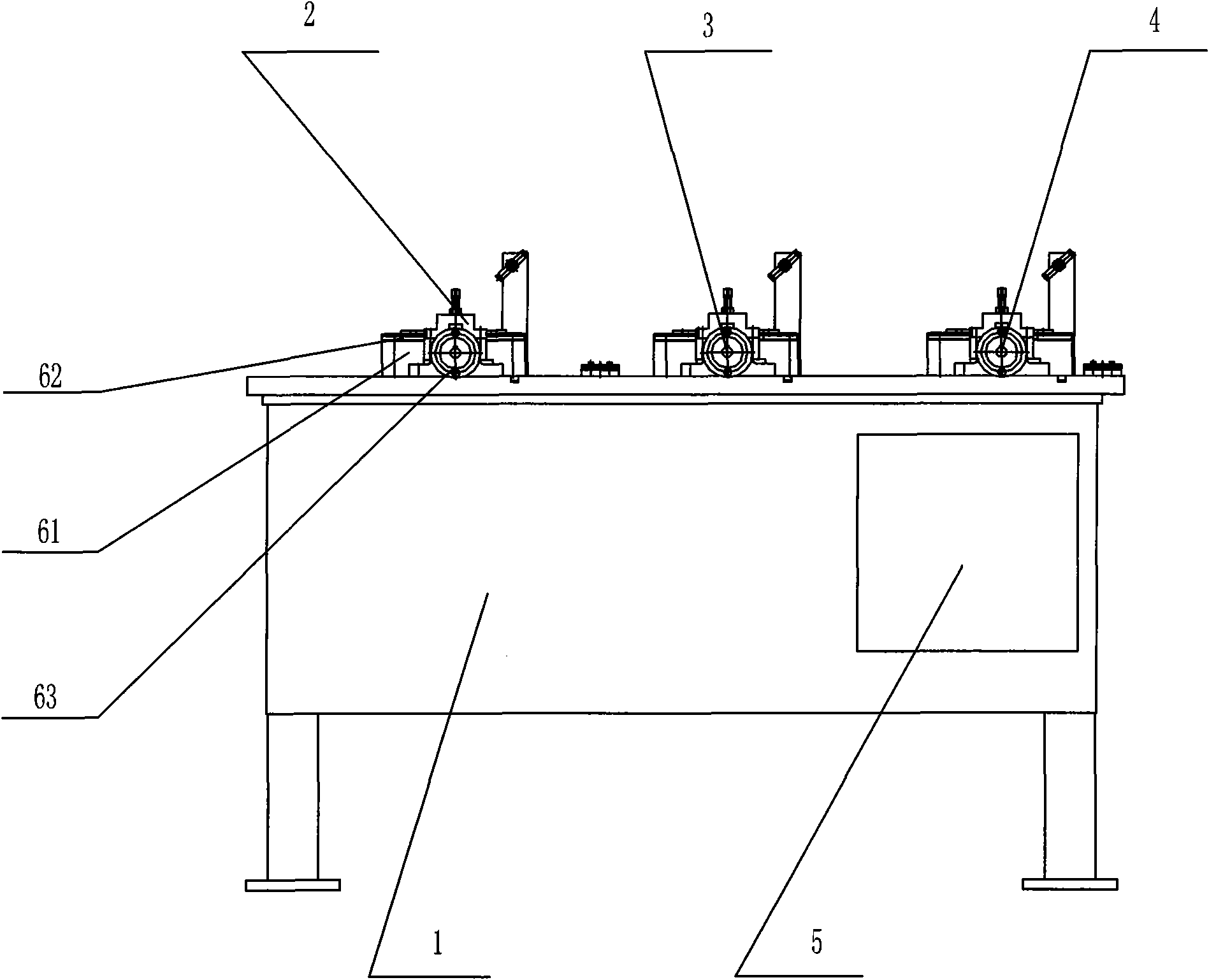

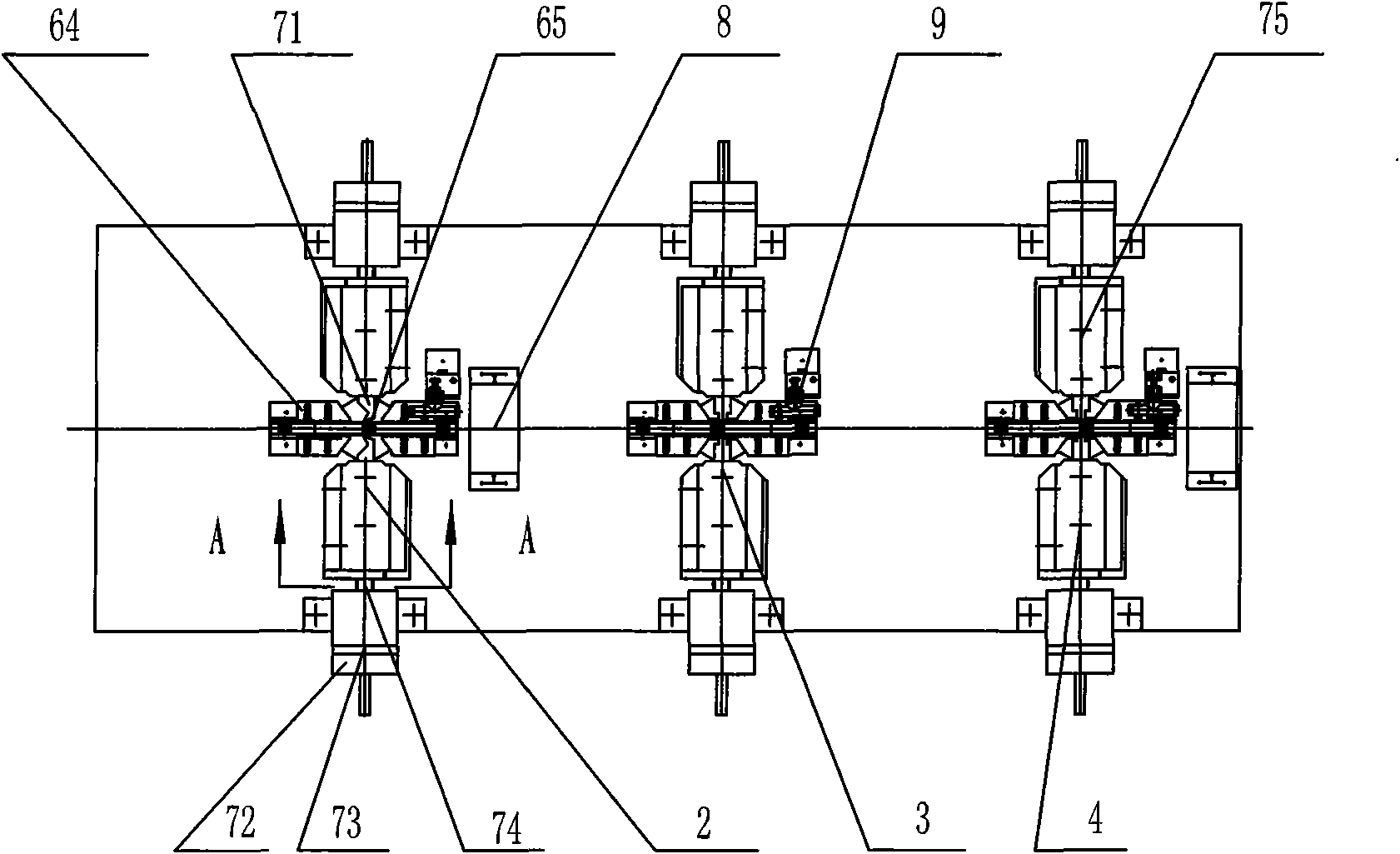

[0017] Such as Figures 1 to 3 As shown, the edge planer for steel strips according to the present invention includes a body 1 and a workbench arranged on the body 1, on which the bottom chamfering planing device 2, End face planing device 3 and upper chamfering planing device 4 .

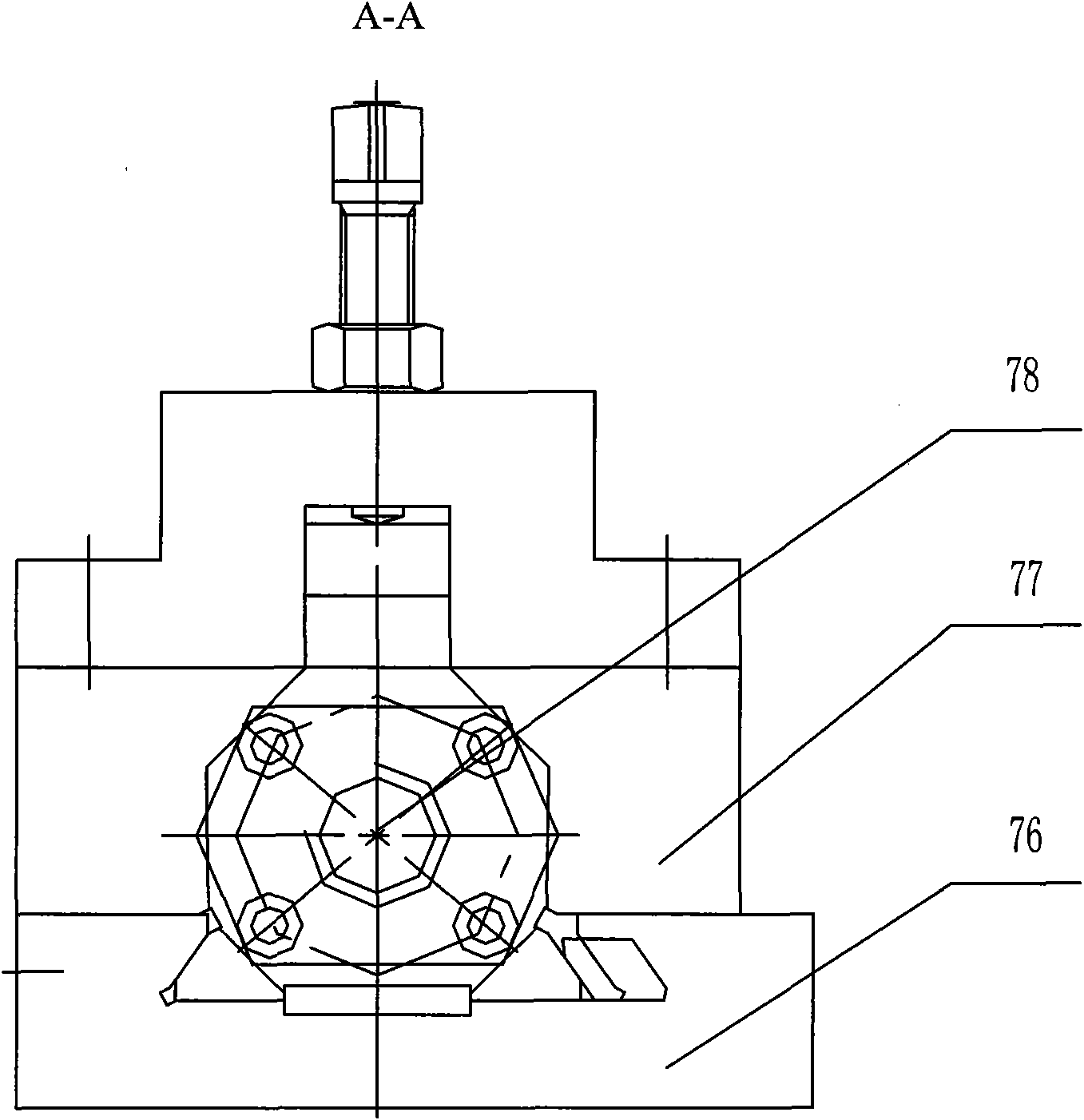

[0018] Described lower chamfering planing device 2, end face planing device 3 and upper chamfering planing device 4 are basically the same in structure, but the tool needs to be installed according to the processing procedure requirements it carries out, the lower chamfering planing device 2, The end face planing device 3 and the upper chamfering planing device 2 all include a guide clamping mechanism and two symmetrically arranged cutter feed mechanisms respectively, and the guide clamp mechanism is located in the middle of the two cutter feed mechanisms, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com