Padding type yarn continuous mercerizing bleaching and dyeing process and device thereof

A dyeing equipment and mercerizing technology, applied in the field of yarn dyeing process and its equipment, can solve the problems of discontinuous traditional process, low production efficiency and high production cost, and achieve good softness, high production efficiency and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

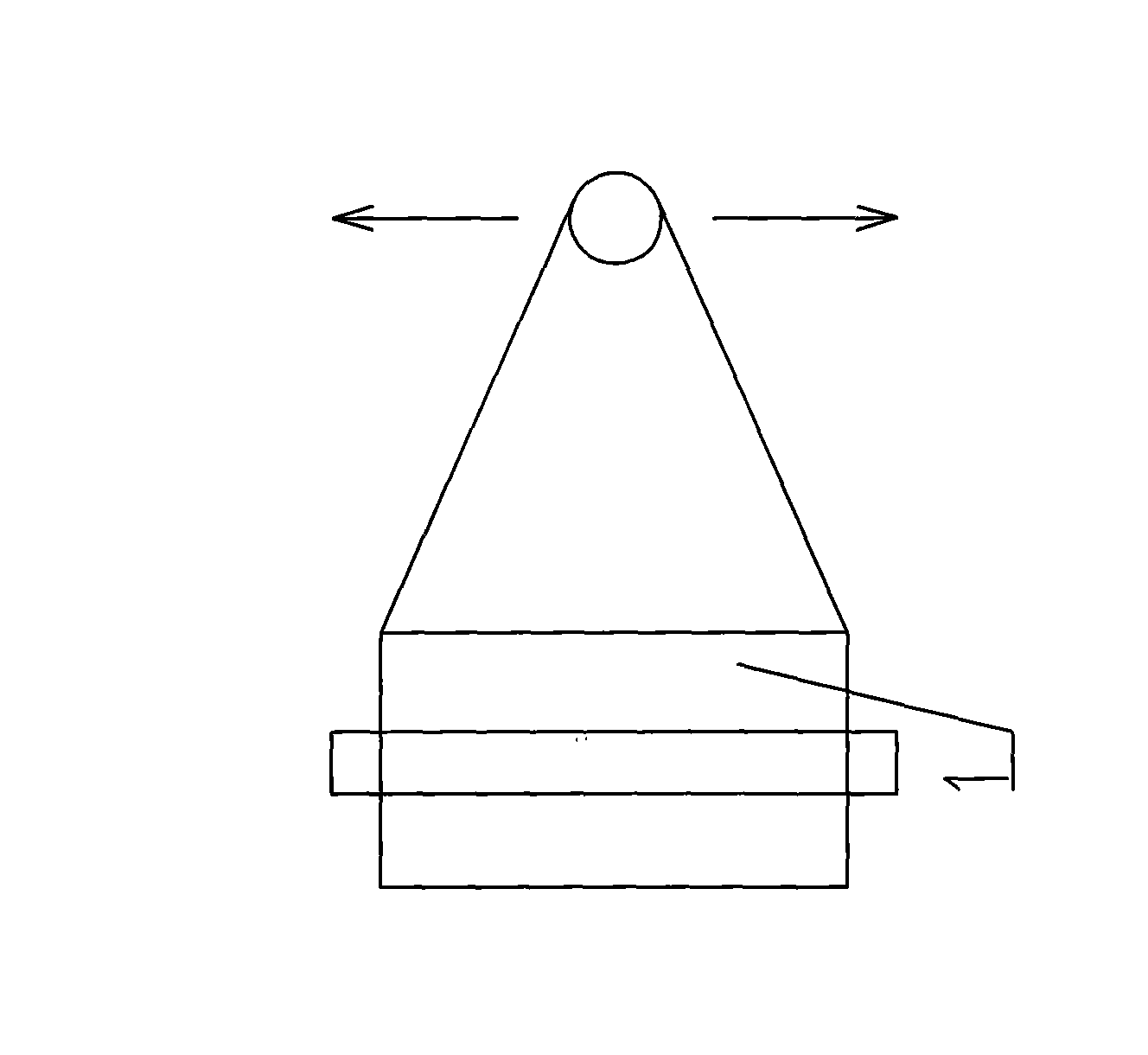

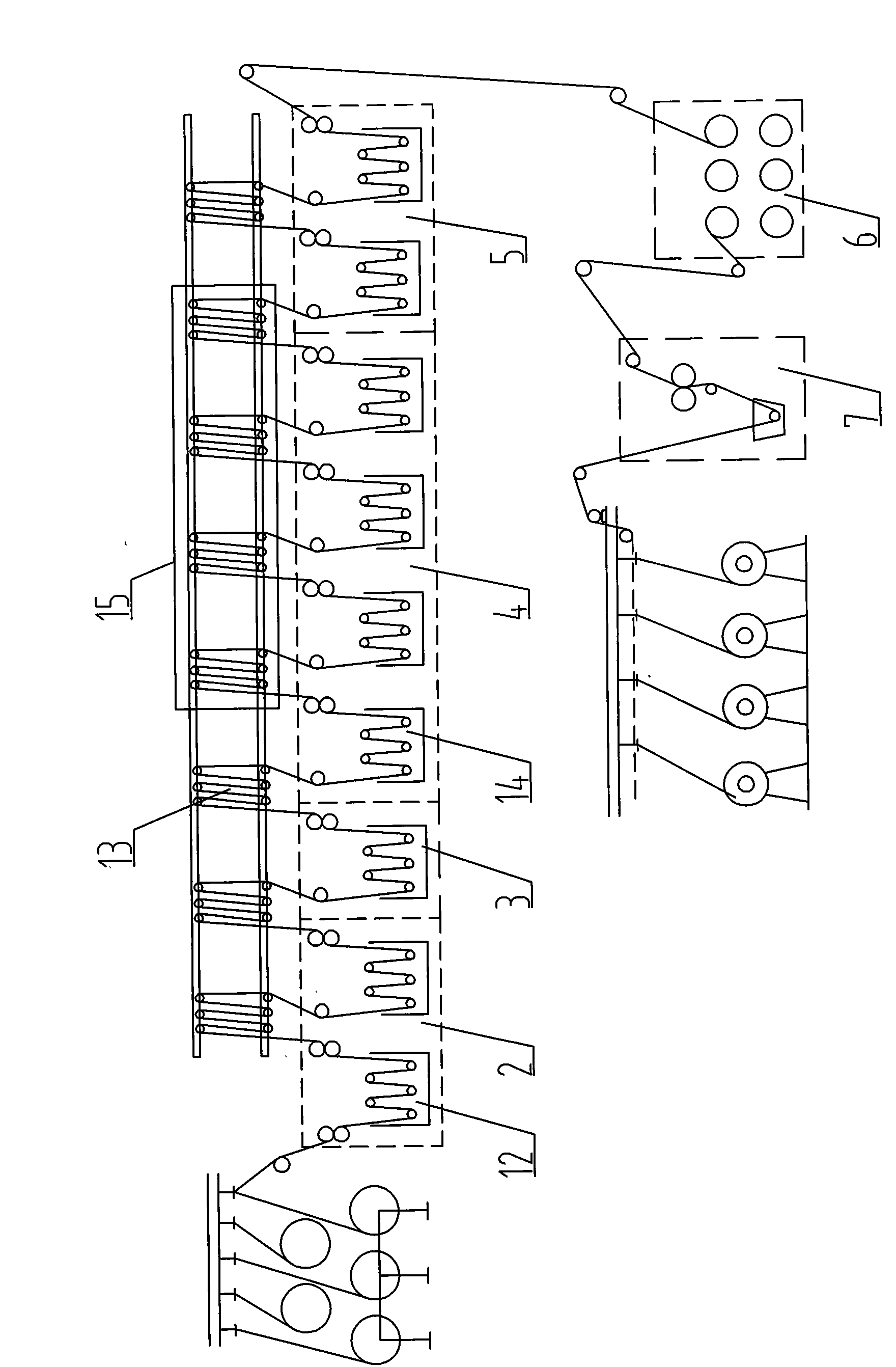

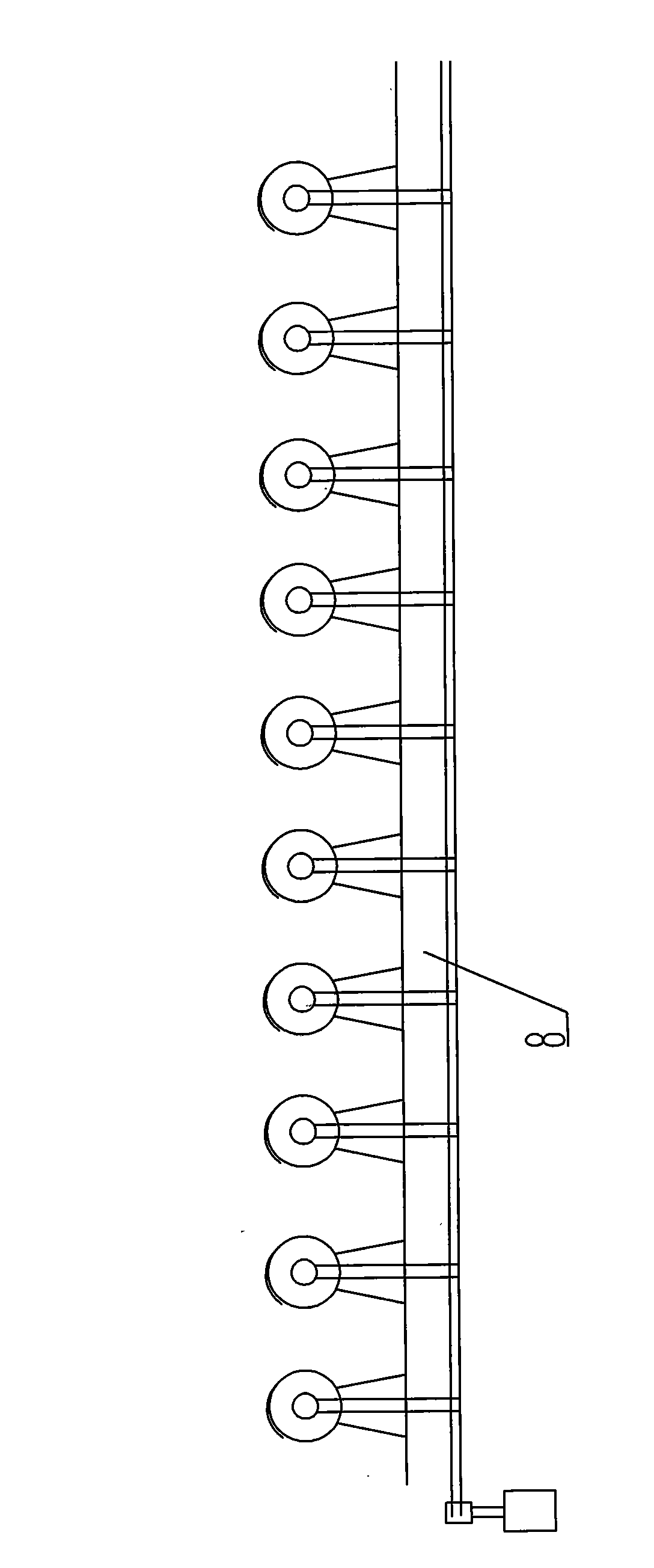

[0019] Such as figure 1 , 2 , shown in 3, 4, a kind of padding type yarn continuous mercerizing bleaching and dyeing process has following process steps successively: Ball warping becomes a ball: with the ball warping machine 1 under the same tension, the bundled yarn is reciprocally spirally wound to On the warp beam; continuous mercerizing bleaching: immerse the bundled yarn delivered in the mercerizing working solution containing 260g / L caustic soda and 1g / L glazing penetrating agent for two consecutive normal temperature padding, and then carry out 70 ℃ hot water washing; then immerse the bundled yarn in the bleaching working solution for at least 4 times of continuous padding at 90℃~95℃, the bleaching working solution contains 2~10g / L H 2 o 2 , 10-20g / L of water glass, 10g / L of caustic soda, 0-5g / L of horseradish and 1-5g / L of alkali-resistant penetrant to ensure that the bleaching time reaches 1Omin, which is the first in the bleaching working solution , H used in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com