System and method for controlling medium consistency disc grinder in a fine tuning way

A technology of fine-tuning control and disc refiner, which is applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc. It can solve problems such as inability to carry out normal production, product quality fluctuations, and unstable production, and achieve optimal The distribution and beating process is stable and the effect of reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

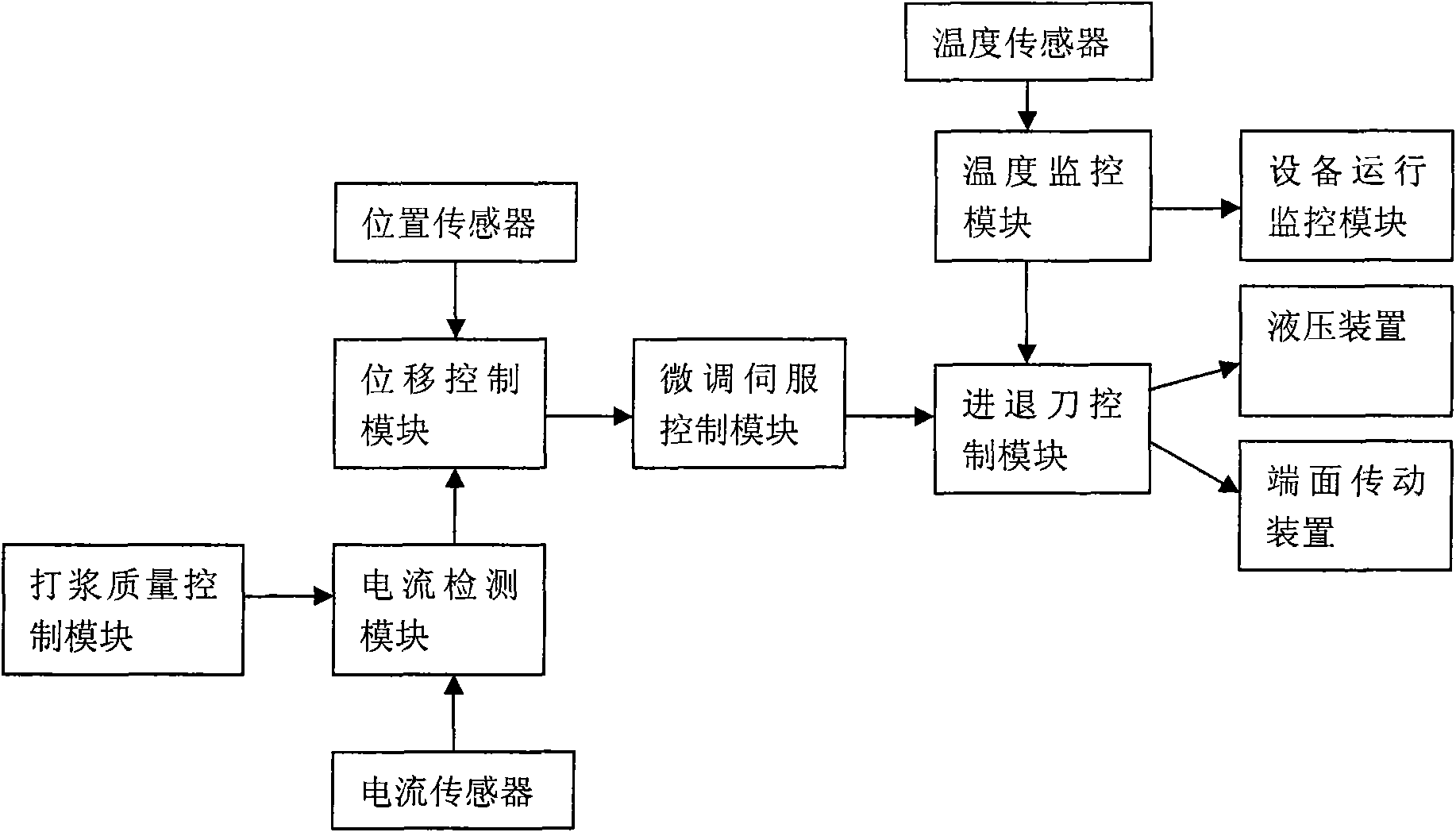

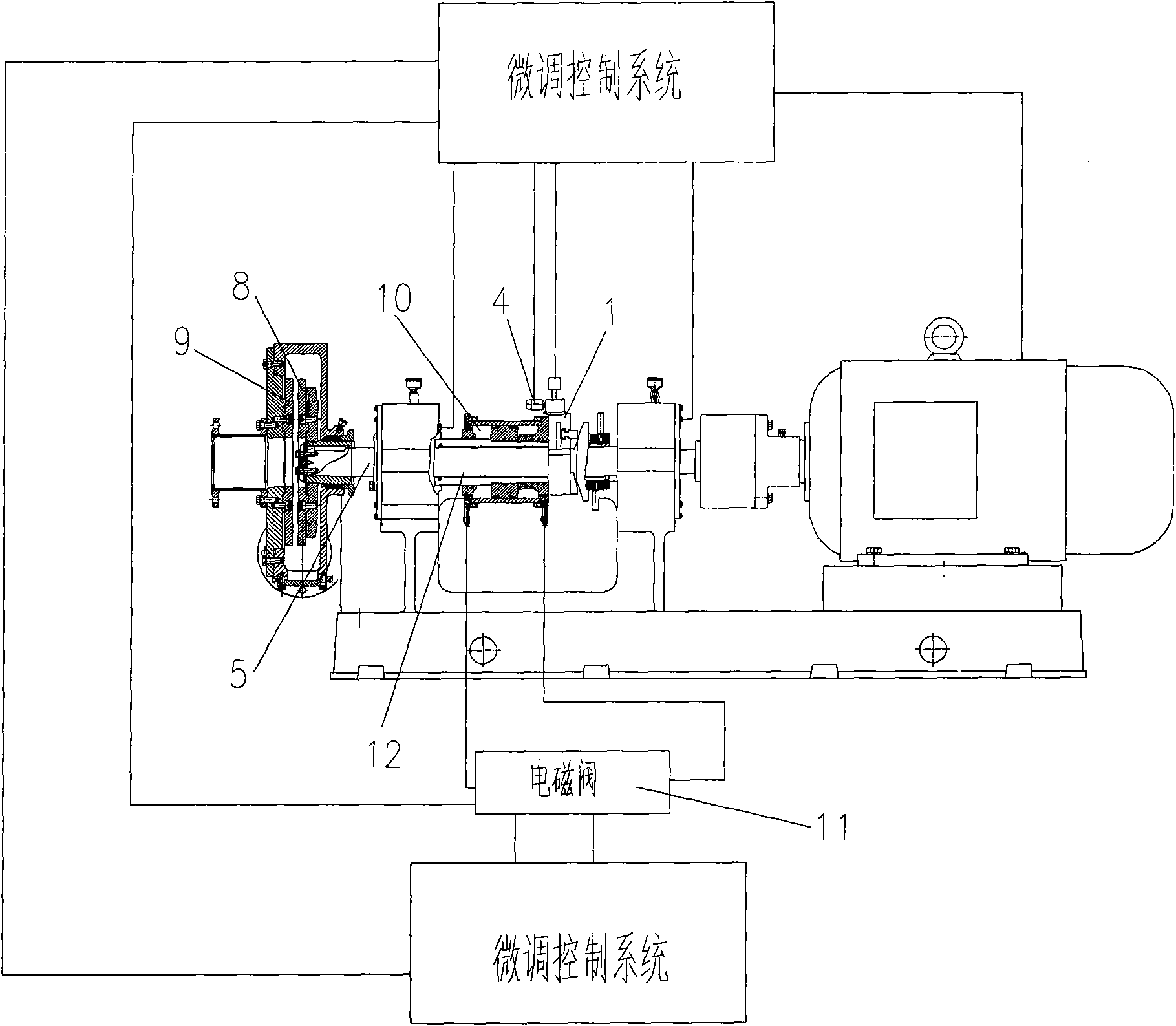

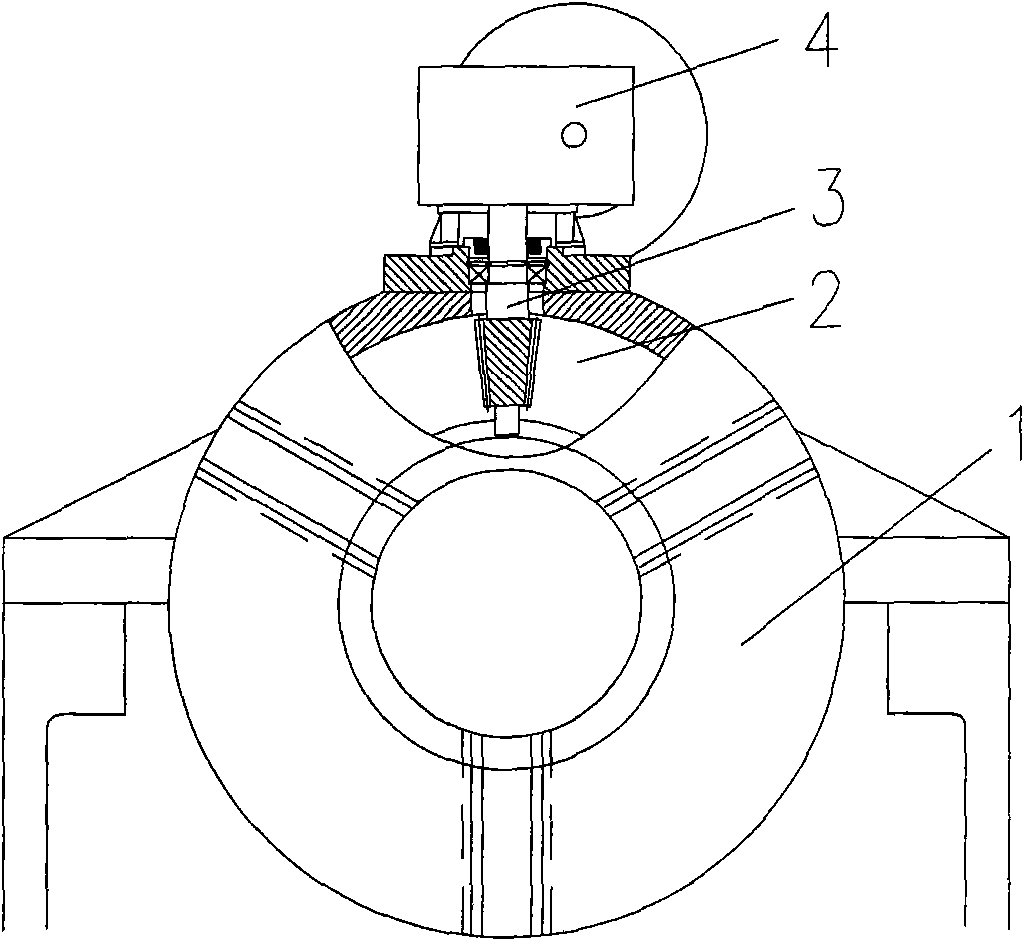

[0037] In this embodiment, a fine-tuning control system for a medium-consistency disc mill, such as figure 1 As shown, it includes a temperature monitoring module, an equipment operation monitoring module, a beating quality control module, a current detection module, a displacement control module, a fine-tuning servo control module, and a knife advance and retreat control module. The output terminals of the equipment are respectively connected with the equipment operation monitoring module and the knife advance and retreat control module, the beating quality control module, the current detection module, the displacement control module, the fine-tuning servo control module and the knife advance and retreat control module are connected in sequence, and the output ends of the knife advance and retreat control module are respectively connected to the The hydraulic device and the end face transmission device of the disc mill; the input end of the displacement control module is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com